pipe truss

Pipe truss refers to a lattice structure composed of round rods connected to each other at the ends. The trusses make the truss structure economical in materials and light in weight, and are easy to form various shapes to suit different purposes, such as simply supported trusses, arches, frames and towers.

In recent years, with the continuous growth of my country’s steel production, pipe trusses are being used more and more widely, accounting for an increasing proportion of buildings, industrial plants, automobiles and other industry equipment platform production lines, logistics warehousing, public buildings Gymnasiums, business clubs, high-speed rail platforms, subway platforms, high-rise commercial buildings, etc. are widely used. The steel pipe structure has also made a big breakthrough. The biggest advantage of the steel pipe structure is that it can perfectly combine people’s functional requirements, sensory requirements and economic benefit requirements for buildings.

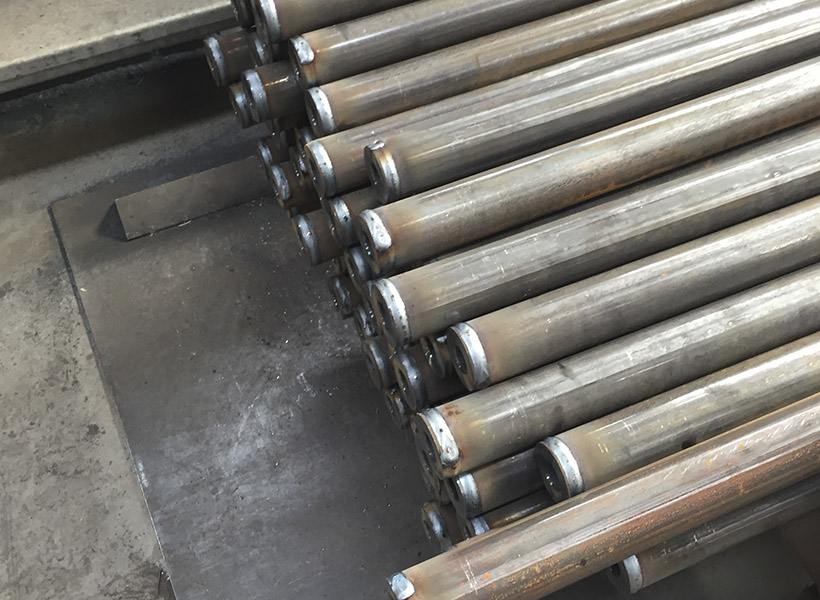

Production and processing display

product description

Compared with the grid structure, the Pipe truss structure saves the lower chord longitudinal members and the ball joints of the grid, which can meet the requirements of various architectural forms, especially the construction of round arches and arbitrary curved shapes has more advantages than the grid structure. Its isotropic stability is the same, saving material consumption. The steel pipe truss structure is developed on the basis of the grid structure. Compared with the grid structure, it has its unique advantages and practicability, and the amount of steel used in the structure is also more economical.

Compared with the traditional open section (H-shaped steel and I-shaped steel) steel pipe truss, the section material of the pipe truss structure is more evenly distributed around the neutral axis, so that the section has good compressive and bending torsional bearing capacity and greater rigidity at the same time. Simple structure without gusset plate. The most important thing is that the pipe truss structure has a beautiful appearance, which is convenient for modeling and has a certain decorative effect. The overall performance of the pipe truss structure is good, the torsional rigidity is large and the appearance is beautiful, and it is relatively easy to manufacture, install, turn over, and lift; the steel pipe roof truss made of cold-formed thin-walled steel has light structure, good rigidity, and saves steel. Advantages such as material strength, especially in the compression rod and support system controlled by the slenderness ratio, are more economical. The buildings that adopt this structure basically belong to public buildings at present. The structure has the characteristics of beautiful appearance (flat plate shape, circular arch shape, arbitrary curve shape), convenient manufacture and installation, good structural stability, high roof rigidity, and good economic effect.

Construction Site

product detail presentation

Applications

Pipe Truss refers to a lattice structure composed of rods connected to each other at the ends, and Pipe truss means that the rods in the structure are all round pipe rods. In most cases, the rods in the truss are only subjected to axial tension or pressure, and the stress is evenly distributed on the cross-section, so it is easy to play the role of the material. These characteristics make the truss structure economical in materials and small in weight. It is easy to form various shapes to suit different purposes, for example, it can be made into simply supported trusses, arches, frames and towers, etc. Therefore, truss structures are used in many large-span venue buildings today, such as convention centers, stadiums or other large-scale buildings. It is widely used in public buildings.

Most of the rods in the truss structure are connected by welding at the joints, and before welding, it is necessary to pre-cut the web and chord according to the weld shape of each rod to be welded, which requires the web Intersecting line cutting at the end and slotting of the chord. Since the bars in the truss structure intersect with each other in the form of intersecting lines, and the cross-sectional shape of the end of the bars is relatively complicated, two methods of mechanical automatic cutting and manual cutting are generally used in the actual cutting process. processing.

Enterprise strength