Standard Specification for Welded and Seamless Steel Pipe Piles1

This standard is issued under the fixed designation A 252; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers nominal (average) wall steel pipe piles of cylindrical shape and applies to pipe piles in

which the steel cylinder acts as a permanent load-carrying member, or as a shell to form cast-in-place concrete piles.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions of the values in inch-pound units to values in SI units.

1.3 The text of this specification contains notes and footnotes that provide explanatory material. Such notes and footnotes, excluding those in tables and figures, do not contain any

mandatory requirements.

1.4 The following precautionary caveat pertains only to the test method portion, Section 16 of this specification. This

standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user

of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

|

Products Details

|

|||||

|

Commodity

|

Competitice price / quality ERW/ SSAW / LSAW steel pipe pile

|

||||

|

Outer diameter

|

ERW / HFW

|

LSAW / DSAW

|

SSAW / HSAW

|

RHS

|

SHS

|

|

1/8 – 20 inch

(10.3 – 508 mm) |

12 – 56 inch

(323.8 – 1,420 mm) |

8 – 126 inch

(219.1 – 3,200 mm) |

40 x 20 mm –

1,000 x 800 mm |

15 x 15 mm –

1,000 × 1,000 mm |

|

|

Wall thickness

|

0.4 – 16 mm

|

6.0 – 40 mm

|

6.0 – 26 mm

|

1.0 – 30 mm

|

0.6 – 30 mm

|

|

Length

|

5.8 ~ 12.0 m or upon customers’ requirements

|

||||

|

Standard

|

GB/T 3091, GB/T 13793, ASTM A252, ASTM A53, ASTM A500, EN 10210, EN 10219, API 5L,

DIN 1626/1615, DIN 17120, etc. |

||||

|

Grade

|

SS400, Q235, Q345, Q460, A572 Gr.50, A572 Gr.60, S235, S275, S355, Grade A/B, X42, X52,

X60, X70, etc. |

||||

|

Surface

|

Prime quality (bared, oiled, color paint, 3LPE, or other anti-corrosive treatment)

|

||||

|

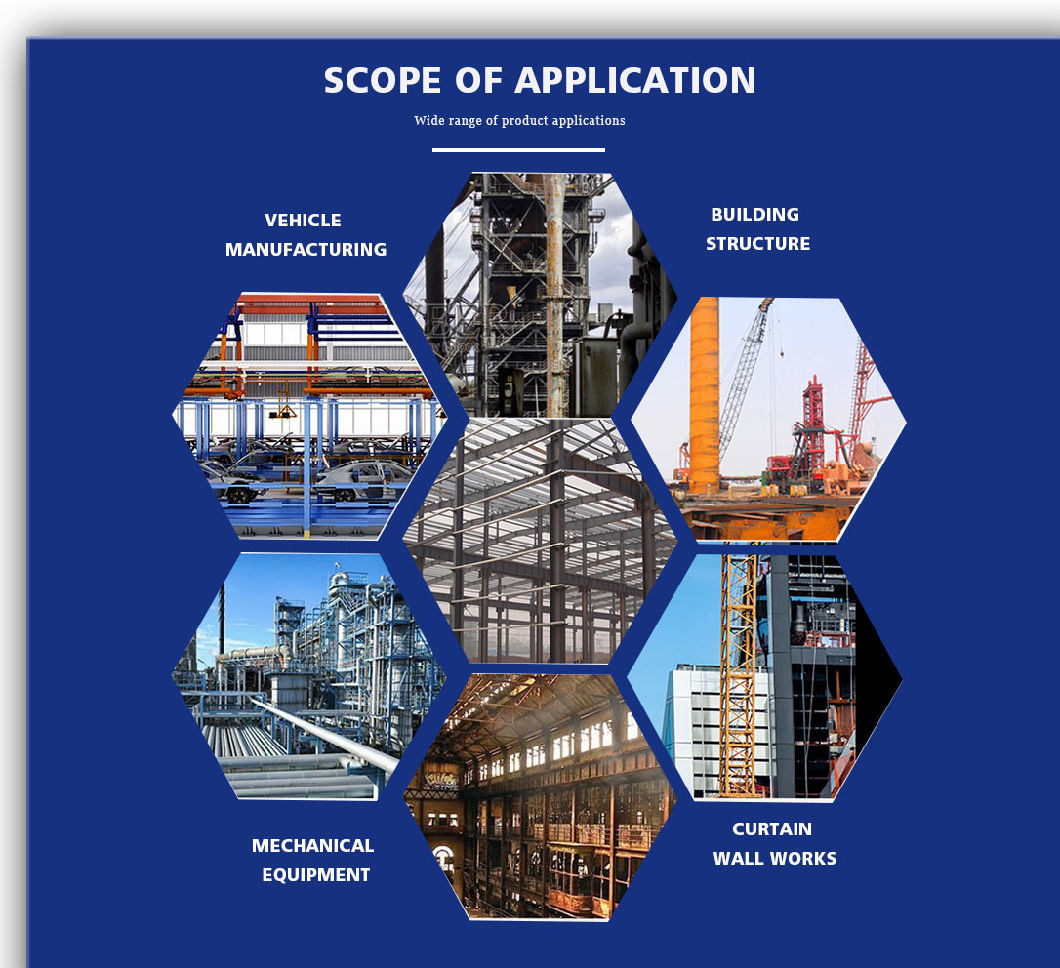

Application

|

structure, electric power transmission tower projects, piling, water, oil & gas pipeline engineering, mechanical industry,

municipal projects, roads and its auxiliary facilities, etc. |

||||

|

Packing

|

Standard export, in bulk / bundles / nylon fabric bags with seaworthy packing;

or according to customers’ requestments. |

||||

|

Delivery Time

|

1. 20-45 days after received deposit or confirmed L/C

2. Depends on your oder quantity |

||||

|

Payment Terms

|

1. T/T: 30% T/T advance, 70% balance copy of B/L

2. L/C: at sight 3. T/T and L/C: 30% T/T advance, 70% L/C |

||||

|

Port

|

China main port

|

||||

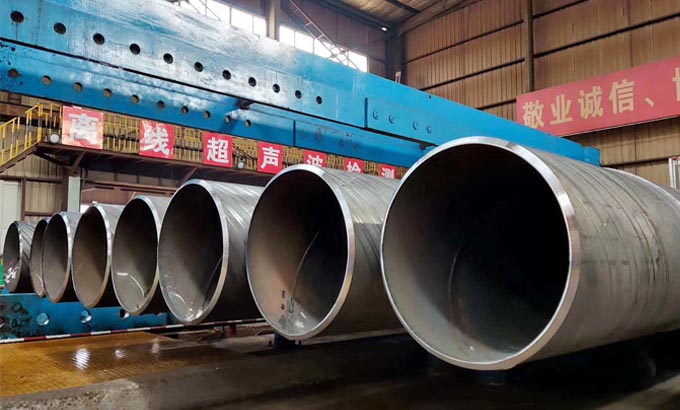

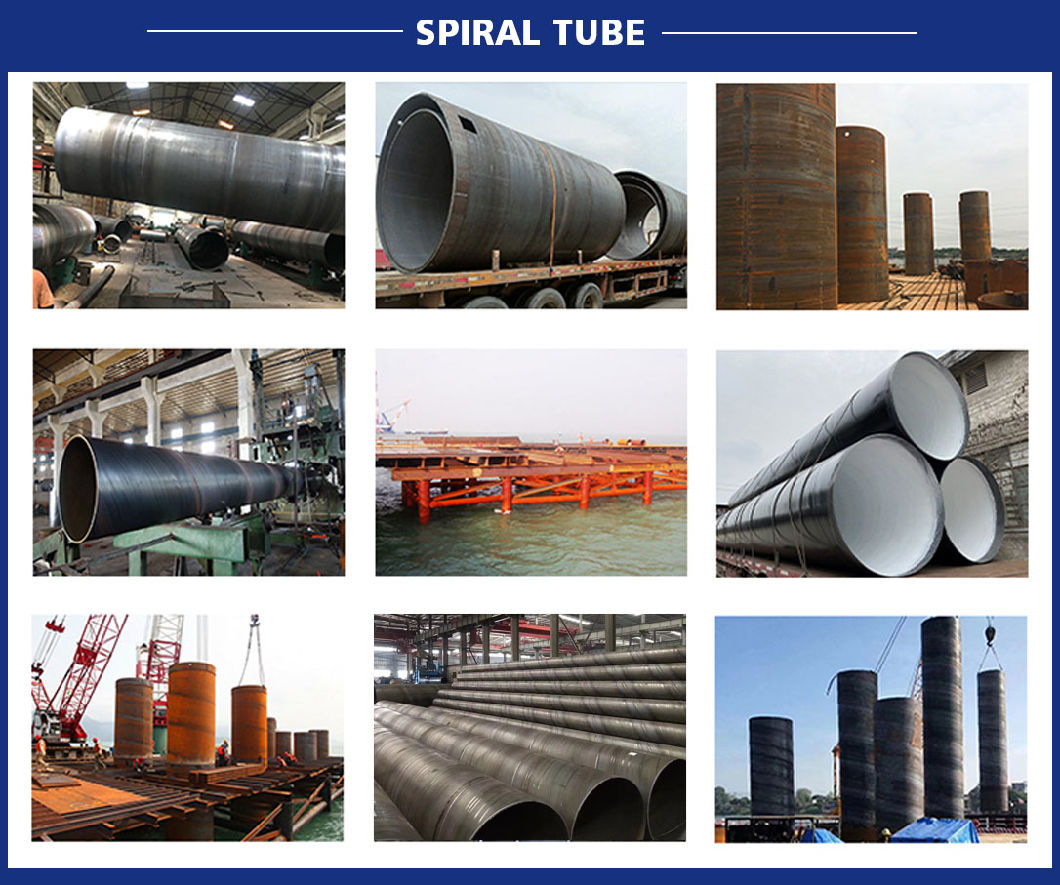

When the cofferdam is used, the steel pipe piles are overlapped with each other in an arc or circular shape. It can enclose water, soil and sand. The utility model has the advantages of novel design, simple structure, convenient use, easy lapping and good sealing. It includes non-circular cross section profile, equal wall thickness, variable wall thickness, variable diameter and variable wall thickness along the length direction, symmetric and asymmetric cross section, etc. Such as square, rectangular, tapered, trapezoidal, spiral tube, etc.

When the cofferdam is used, the steel pipe piles are overlapped with each other in an arc or circular shape. It can enclose water, soil and sand. The utility model has the advantages of novel design, simple structure, convenient use, easy lapping and good sealing. It includes non-circular cross section profile, equal wall thickness, variable wall thickness, variable diameter and variable wall thickness along the length direction, symmetric and asymmetric cross section, etc. Such as square, rectangular, tapered, trapezoidal, spiral tube, etc.

2. Referenced Documents

2.1 ASTM Standards:

A 370 Test Methods and Definitions for Mechanical Testing

of Steel Products2

A 751 Test Methods, Practices, and Terminology for

Chemical Analysis of Steel Products2

A 941 Terminology Relating to Steel, Stainless Steel, Related Alloys, and Ferroalloys3

E 29 Practice for Using Significant Digits in Test Data to

Determine Conformance with Specifications

3. Terminology

3.1 Definitions—Definitions of terms used in this specification shall be in accordance with Terminology A 941.

3.1.1 defect—an imperfection of sufficient size or magnitude to be cause for rejection.

3.1.2 imperfection—any discontinuity or irregularity found

in the pipe.

4. Ordering Information

4.1 Orders for material under this specification shall contain

information concerning as many of the following items as are

required to describe the desired material adequately:

4.1.1 Quantity (feet or number of lengths),

4.1.2 Name of material (steel pipe piles),

4.1.3 Method of manufacture (seamless or welded),

4.1.4 Grade (Tables 1 and 2),

4.1.5 Size (outside diameter and nominal wall thickness),

4.1.6 Lengths (single random, double random, or uniform)

(see Section 13),

4.1.7 End finish (Section 15), and

4.1.8 ASTM specification designation and year of issue,

4.1.9 Location of purchaser’s inspection (see 19.1), and

4.1.10 Bar coding (see 22.2).

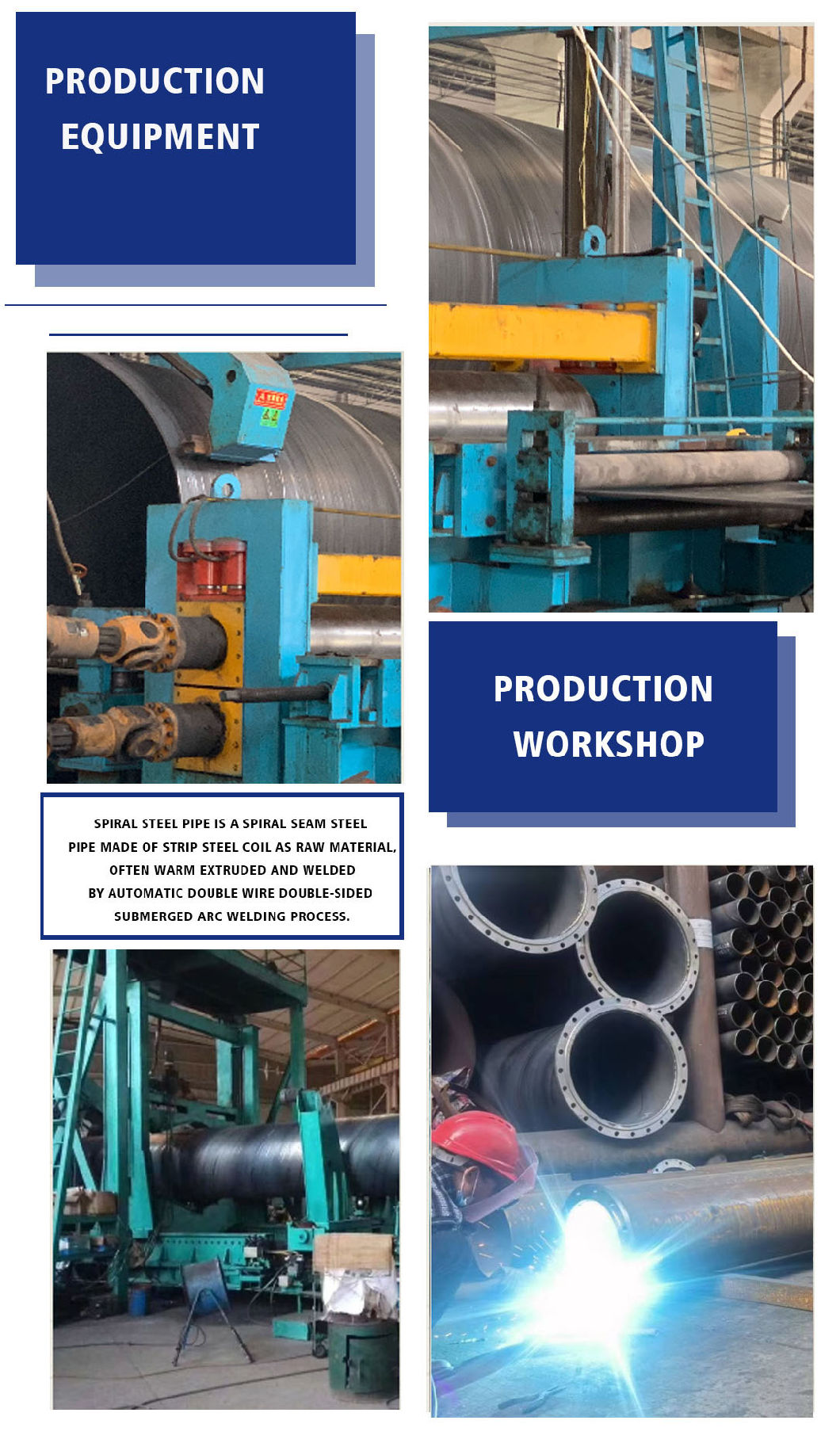

5. Materials and Manufacture

5.1 The piles shall be made by the seamless, electric

resistance welded, flash welded, or fusion welded process. The

seams of welded pipe piles shall be longitudinal, helical-butt,

or helical-lap.

NOTE 1—For welded pipe piles, the weld should not fail when the

product is properly fabricated and installed and subjected to its intended

end use.

6. Process

6.1 The steel shall be made by one or more of the following

processes: open-hearth, basic-oxygen, or electric-furnace.

7. Chemical Composition

7.1 The steel shall contain no more than 0.050 % phosphorous.

8. Heat Analysis

8.1 Each heat analysis shall conform to the requirement

specified in 7.1. When requested by the purchaser, the applicable heat analyses shall be reported to the purchaser ro the

purchaser’s representative.

9. Product Analysis

9.1 Chemical analysis shall be in accordance with Test

Methods, Practices, and Terminology A 751.

9.2 It shall be permissible for the purchaser to make product

analyses using samples from lots of pipe piles as follows:

Pipe Size Outside

Diameter, in. (mm)

Number of Samples and Size of Lot

Under 14 (355.6) 2 from 200 pipe or fraction thereof

14 to 36, incl (355.6

to 914)

2 from 100 pipe or fraction thereof

Over 36 (914) 2 from 3000 ft (914 m) or fraction thereof

The product analyses shall conform to the requirement in

7.1.

9.3 If the chemical compositions of both of the samples

representing a lot fail to conform to the specified requirement,

the lot shall be rejected or analyses of four additional samples

selected from the lot shall be made, and each shall conform to

the specified requirement. If the chemical composition of only

one of the samples representing a lot fails to conform to the

specified requirement, the lot shall be rejected or analyses of

two additional samples selected from the lot shall be made, and

each shall conform to the specified requirement.

10. Tensile Requirements

10.1 The material shall conform to the requirements as to

tensile properties prescribed in Tables 1 and 2.

10.2 The yield point shall be determined by the drop of the

beam, by the halt in the gage of the testing machine, by the use

of dividers, or by other approved methods. When a definite

yield point is not exhibited, the yield strength corresponding to

a permanent offset of 0.2 % of the gage length of the specimen,

or to a total extension of 0.5 % of the gage length under load

shall be determined.

11. Weights Per Unit Length

11.1 The weights per unit length for various sizes of pipe

piles are listed in Table 3.

11.2 For pipe pile sizes not listed in Table 3, the weight per

unit length shall be calculated as follows:

W5 10.69~D 2 t!t (1)

W = weight per unit length, lb/ft,

D = specified outside diameter, in., and

t = specified nominal wall thickness, in.

12. Permissible Variations in Weights and Dimensions

12.1 Weight—Each length of pipe pile shall be weighed

separately and its weight shall not vary more than 15 % over or

5 % under its theoretical weight, calculated using its length and

its weight per unit length (see Section 11).

12.2 Outside Diameter—The outside diameter of pipe piles

shall not vary more than 61 % from the specified outside

diameter.

12.3 Wall Thickness—The wall thickness at any point shall

not be more than 12.5 % under the specified nominal wa

shown in Table X1.1 (see Appendix) for various nominal wall thicknesses.

13. Lengths

13.1 Pipe piles shall be furnished in single random lengths,

double random lengths, or in uniform lengths as specified in

the purchase order, in accordance with the following limits:

Single random lengths 16 to 25 ft (4.88 to 7.62 mm), incl

Double random lengths over 25 ft (7.62 m) with a minimum average

of 35 ft (10.67 m)

Uniform lengths length as specified with a permissible variation of 61 in.

13.2 Lengths that have been spliced at the mill by welding

shall be acceptable as the equivalent of unspliced lengths

provided tension test specimens cut from sample splices

conform to the tensile strength requirements prescribed in

Tables 1 and 2. The welding bead shall not be removed for this

test. Such specimens shall be made in accordance with the

provisions specified in Sections 16-18

PDF DOWNLOADS : ASTM A252 Standard-Specification-for-Welded-and-Seamless-Steel-Pipe-Piles