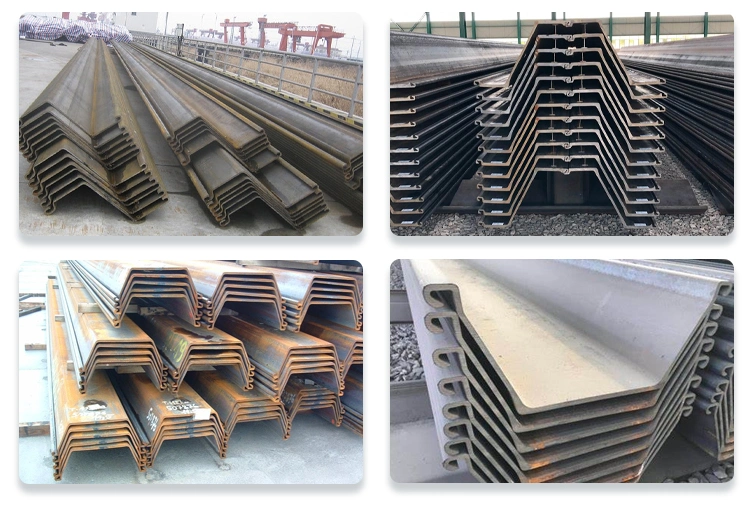

Steel Pipe Piles / Steel Pipe Sheet Piles

Steel pipe piles and steel pipe sheet piles are essential components in various construction projects, particularly in foundation and retaining wall systems. They offer numerous advantages that make them a popular choice among engineers and contractors. Let’s explore the salient features and benefits of using steel pipe piles and steel pipe sheet piles.

1. Large Vertical-Bearing Capacity

One of the key advantages of steel pipe piles and steel pipe sheet piles is their ability to withstand heavy vertical loads. These piles are designed to support structures and transfer the loads to the underlying soil or rock layers. They offer a high vertical-bearing capacity, making them suitable for constructing deep foundations in challenging soil conditions.

2. High Bending Strength

Steel pipe piles and steel pipe sheet piles possess high bending strength, allowing them to withstand lateral forces and resist deformation. This is crucial in applications where the piles need to resist the lateral pressure exerted by soil or water. The excellent bending strength of these piles ensures stability and durability in various projects, including bridges, wharfs, and waterfront structures.

3. Excellent Environmental Performance

Steel pipe piles and steel pipe sheet piles exhibit excellent environmental performance. They are resistant to corrosion, erosion, and deterioration, even in harsh environments. This makes them an ideal choice for projects located in marine environments, contaminated soils, or areas with high groundwater levels. The durability of these piles ensures the longevity of the structure while minimizing maintenance requirements.

4. Custom Fit for Each Structure

Steel pipe piles and steel pipe sheet piles can be customized to fit the specific requirements of each structure. They are available in various sizes, diameters, and thicknesses, allowing engineers to select the most suitable pile dimensions based on the design and load requirements. This versatility ensures that the piles are tailored to provide optimal performance and efficiency in different projects.

5. Easy Production of Longer Piles and Jointing Piles

Steel pipe piles and steel pipe sheet piles can be easily produced in longer lengths compared to other piling materials. This eliminates or reduces the need for splicing or joining multiple shorter piles together, providing a continuous and seamless foundation system. Longer piles not only simplify the construction process but also enhance the structural integrity and load-bearing capacity.

6. Easy Jointing with Superstructures

Steel pipe piles and steel pipe sheet piles have a straightforward jointing process with superstructures. They can be easily connected to pile caps, pile heads, or other structural components, ensuring a secure and efficient connection. This ease of jointing simplifies the construction process and allows for faster installation, saving time and labor costs.

7. Easy Handling

Steel pipe piles and steel pipe sheet piles are lightweight compared to other types of piles, such as concrete or timber piles. This makes them easier to handle and transport on construction sites. Additionally, their modular nature allows for efficient storage and logistics during the construction process.

In conclusion, steel pipe piles and steel pipe sheet piles offer significant advantages in terms of vertical-bearing capacity, bending strength, environmental performance, customization, production of longer piles, jointing with superstructures, and ease of handling. These factors make them a preferred choice for various construction projects, including foundation systems, retaining walls, marine structures, and waterfront developments.

UOE SAWL PIPES

Outside Diameter:Φ508mm- 1118mm (20″- 44″)

Wall Thickness: 6.0-25.4mm 1/4″-1″

Quality Standards: API,DNV,ISO,DEP,EN,ASTM,DIN,BS,JIS,GB,CSA

Length: 9-12.3m (30′- 40′)

Grades: API 5L A-X90,GB/T9711 L190-L625JCOE SAWL PIPES

Outside Diameter:Φ406mm- 1626mm (16″ – 64″ )

Wall Thickness:6.0- 75mm (1/4″ – 3″ )

Quality Standards:API,DNV,ISO,DEP,EN,ASTM,DIN,BS,JIS,GB,CSA

Length:3-48m

Grades:API 5L A-X100, GB/T9711 L190-L690

Tolerance of Outside Diameter and Wall Thickness

Tolerance of Outside Diameter and Wall Thickness

| Types | Standard | |||||

| SY/T5040-2000 | SY/T5037-2000 | SY/T9711.1-1977 | ASTM A252 | AWWA C200-97 | API 5L PSL1 | |

| Tube end OD deviation | ±0.5%D | ±0.5%D | -0.79mm~+2.38mm | <±0.1%T | <±0.1%T | ±1.6mm |

| Wall thickness | ±10.0%T | D<508mm, ±12.5%T | -8%T~+19.5%T | <-12.5%T | -8%T~+19.5%T | 5.0mm<T<15.0mm, ±0.11 |

| D>508mm, ±10.0%T | T≥15.0mm, ±1.5mm | |||||

Chemical Composition and Mechanical Properties

| Standard | Grade | Chemical Composition(max)% | Mechanical Properties(min) | |||||

| C | Mn | Si | S | P | Yield Strength(Mpa) | Tensile Strength(Mpa) | ||

| GB/T700-2006 | A | 0.22 | 1.4 | 0.35 | 0.050 | 0.045 | 235 | 370 |

| B | 0.2 | 1.4 | 0.35 | 0.045 | 0.045 | 235 | 370 | |

| C | 0.17 | 1.4 | 0.35 | 0.040 | 0.040 | 235 | 370 | |

| D | 0.17 | 1.4 | 0.35 | 0.035 | 0.035 | 235 | 370 | |

| GB/T1591-2009 | A | 0.2 | 1.7 | 0.5 | 0.035 | 0.035 | 345 | 470 |

| B | 0.2 | 1.7 | 0.5 | 0.030 | 0.030 | 345 | 470 | |

| C | 0.2 | 1.7 | 0.5 | 0.030 | 0.030 | 345 | 470 | |

| BS En10025 | S235JR | 0.17 | 1.4 | – | 0.035 | 0.035 | 235 | 360 |

| S275JR | 0.21 | 1.5 | – | 0.035 | 0.035 | 275 | 410 | |

| S355JR | 0.24 | 1.6 | – | 0.035 | 0.035 | 355 | 470 | |

| DIN 17100 | ST37-2 | 0.2 | – | – | 0.050 | 0.050 | 225 | 340 |

| ST44-2 | 0.21 | – | – | 0.050 | 0.050 | 265 | 410 | |

| ST52-3 | 0.2 | 1.6 | 0.55 | 0.040 | 0.040 | 345 | 490 | |

| JIS G3101 | SS400 | – | – | – | 0.050 | 0.050 | 235 | 400 |

| SS490 | – | – | – | 0.050 | 0.050 | 275 | 490 | |

| API 5L PSL1 | A | 0.22 | 0.9 | – | 0.03 | 0.03 | 210 | 335 |

| B | 0.26 | 1.2 | – | 0.03 | 0.03 | 245 | 415 | |

| X42 | 0.26 | 1.3 | – | 0.03 | 0.03 | 290 | 415 | |

| X46 | 0.26 | 1.4 | – | 0.03 | 0.03 | 320 | 435 | |

| X52 | 0.26 | 1.4 | – | 0.03 | 0.03 | 360 | 460 | |

| X56 | 0.26 | 1.1 | – | 0.03 | 0.03 | 390 | 490 | |

| X60 | 0.26 | 1.4 | – | 0.03 | 0.03 | 415 | 520 | |

| X65 | 0.26 | 1.45 | – | 0.03 | 0.03 | 450 | 535 | |

| X70 | 0.26 | 1.65 | – | 0.03 | 0.03 | 585 | 570 | |

Types of galvanized steel pipe

| STANDARDS | PRODUCTS | RANGES |

| IS:1239 (Part-I) | Mild Steel Tubes, Tubular | 15mm NB – 150mm NB |

| IS:1161 | Mild Steel pipe trusses for Structural | 15mm NB – 200mm NB |

| IS:3601 | Mild Steel tubes for Mechanical & General Eng. purpose | 20mm x 0.80mm to 165.10 x 7.00 mm |

| IS:3589 | ERW Pipes for water Gas & Sewage | 168.3 x 4.00 mm to 219.1 x 7.00mm |

| IS:9295 | Steel Tubes for Idlers for Belt conveyors | 63.5 x 4.00 mm to 219.1 x 7.0 mm |

| IS:4270 | Steel Tubes for Water Wells | 114.3 x 5.00mm to 219.1mm x 7.1mm |

| IS:7138 | Steel Tubes for furniture | 20.0 x .60mm to 60.0 x 2.0mm |

| IS:4923 | Hollow Steel sections for structural purpose | 12.5 x 12.5 x 0.80 to 150 x 150 x 6.0mm 10 x 20 x 0.80mm to 150 x 200 x 6.0mm |

| IS:3074 | Steel Tubes for Automobile purpose | 19.7 x 1.00mm to 101.6 x 6.0mm |

| BS:1387 | Screwed & Socket Steel Tubes & Tubular | ½”NB to 6″NB 2.00 mm – 5.40 mm wall thick |

| BS:3601 | Steel Pipes & Tubes for pressure purpose | ½”NB to 6″NB 2.00 mm – 7.00 mm wall thickness |

| BS:6323 | Steel tubes for mechanical & general engineering purposes | 21.3″ to 219.1mm OD wall thickness-1.60-7.00 mm |

FAQ

- What are steel pipe piles and steel pipe sheet piles?

Steel pipe piles and steel pipe Z sheet pile are components used in foundation and retaining wall systems to support vertical loads and resist lateral forces. They are typically made of steel and possess unique properties suitable for various construction applications. - What is the vertical-bearing capacity of steel pipe piles and steel pipe sheet piles?

Steel pipe piles and steel pipe sheet piles offer a large vertical-bearing capacity, allowing them to support heavy loads and transfer them to the underlying soil or rock layers. - Are steel pipe piles and steel sheet pile resistant to corrosion?

Yes, these piles exhibit excellent resistance to corrosion, erosion, and deterioration, ensuring long-term durability and environmental performance. - Can steel pipe piles and steel pipe sheet piles be customized for each structure?

Yes, these piles can be customized in terms of size, diameter, and thickness to meet the specific requirements of each structure, ensuring optimal performance and efficiency. - Are steel pipe piles and steel pipe sheet piles lightweight and easy to handle?

Yes, these piles are relatively lightweight compared to other types of piles, making them easier to handle, transport, and store on construction sites.

It is important to consult with a professional engineer or contractor for specific design considerations and recommendations based on the project requirements.