Galvanized Bridge Slot Screen Pipe: Enhancing Filtration Efficiency and Durability

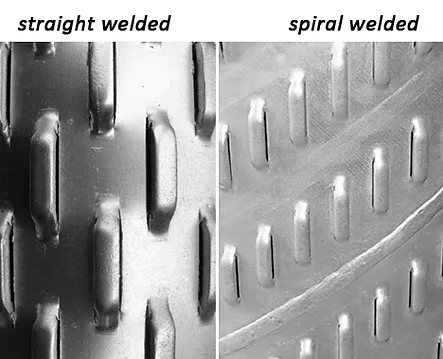

A galvanized bridge slot screen pipe is a type of filtration pipe that offers enhanced durability and corrosion resistance. Manufactured using a straight seam welded (ERW) or spiral welded (SSAW) process, this pipe is designed to effectively control sand and other particles in various applications. In this article, we will explore the advantages of galvanized bridge slot screens, their specifications, and their applications in different industries.

Manufacturing Process and Slot Patterns:

The manufacturing process of galvanized bridge slot screens involves pressing flat sheets or plates of bridge-type perforated steel into cylinders, which are then seam welded. This process ensures a strong and seamless construction, capable of withstanding high pressures and harsh environments. Additionally, there are two options for the bridge-type slot patterns: straight in rows and staggered. These patterns provide flexibility in filtration performance based on specific requirements.

Advantages of Galvanized Bridge Slot Screens:

Galvanized bridge slot screens offer several advantages over other sand control screens. Some of the key advantages include:

- Non-Plugging: The unique structure of the slot design makes it difficult for particles to get stuck, preventing clogging and improving the discharge capacity. This non-plugging feature ensures efficient filtration performance, even in challenging conditions.

- High Mechanical Strength: The special construction of galvanized bridge slot screens enhances their mechanical strength. This allows them to withstand high pressures, resist deformation, and provide long-term durability. The galvanized coating further enhances the strength and corrosion resistance of the screens.

- Flexible Customization: Galvanized bridge slot screens can be custom-made to meet specific requirements. The slot size can be adjusted to accommodate different filtration needs, providing flexibility in achieving optimal filtration performance. This customization ensures that the screens are tailored to the unique demands of each project.

- Lightweight and Cost-Effective: Galvanized bridge slot screens are lighter in weight compared to other sand control screens, making them easier to handle and install. Additionally, they are often more cost-effective, offering a budget-friendly solution without compromising on performance. The galvanized coating also contributes to their cost-effectiveness by extending the service life of the screens.

Specifications of Galvanized Bridge Slot Screens:

Galvanized bridge slot screens are available in various specifications to suit different applications. Some common specifications include:

- Wall Thickness: The wall thickness of galvanized bridge slot screens typically ranges from 3mm to 10mm. This thickness ensures structural integrity and durability, while the galvanized coating provides added protection against corrosion.

- Outside Diameter: The outside diameter of galvanized bridge slot screens can vary from 89mm to 2000mm, providing flexibility in choosing the appropriate size for specific projects. The larger diameter screens are suitable for applications that require higher flow rates.

- Slot Width: The slot width of galvanized bridge slot screens can range from 0.5mm to 5mm. This precise slot size allows for effective filtration while minimizing the risk of clogging. The galvanized coating on the screens ensures that the slots remain clear and unobstructed.

- Length: Galvanized bridge slot screens are available in lengths of up to 12 meters, allowing for customization based on the depth and requirements of the filtration project. Longer screens can be used to cover larger areas and provide continuous filtration.

- End Connection: The end connections of galvanized bridge slot screens can be plain beveled, flanged, or couplings, providing options for easy installation and connection to other components. The galvanized coating on the screens ensures a secure and leak-free connection.

Applications of Galvanized Bridge Slot Screens:

Galvanized bridge slot screens find applications in various industries and sectors, including:

- Water Wells: Galvanized bridge slot screens are commonly used in water well projects for efficient filtration and sand control. They prevent the entry of sand and other unwanted particles while allowing the flow of water. The galvanized coating protects the screens from corrosion caused by exposure to groundwater.

- Mining and Mineral Processing: Galvanized bridge slot screens are utilized in mining and mineral processing operations for dewatering, filtration, and separation of materials. They aid in the removal of solids and ensure the smooth flow of liquids. The galvanized coating provides resistance against corrosive substances present in mining environments.

- Municipal Water Supply: Galvanized bridge slot screens play a crucial role in municipal water supply systems, providing effective filtration to remove impurities and ensure the delivery of clean and safe drinking water. The galvanized coating extends the service life of the screens, reducing maintenance and replacement costs.

- Refining and Petrochemical Industry: Galvanized bridge slot screens are used in the refining and petrochemical industry for filtration and separation processes. They help remove contaminants and ensure the quality of the final product. The galvanized coating protects the screensfrom corrosion caused by exposure to chemicals and harsh substances.

- Water Treatment: Galvanized bridge slot screens are widely employed in water treatment plants for the filtration and purification of water. They remove suspended solids, sediments, and other impurities, ensuring the production of clean and safe water. The galvanized coating enhances the longevity of the screens, reducing the need for frequent replacements.

- Architecture and Construction: Galvanized bridge slot screens are also utilized in architectural and construction projects. They are used for drainage systems, retaining walls, and underground structures, providing effective filtration and preventing soil erosion. The galvanized coating protects the screens from corrosion caused by exposure to moisture and environmental elements.

Frequently Asked Questions (FAQ):

- What is the difference between a straight seam welded (ERW) and spiral welded (SSAW) bridge slot screen?

- The difference lies in the manufacturing process. ERW bridge slot screens are manufactured by pressing flat sheets or plates into cylinders and then seam welding them. On the other hand, SSAW bridge slot screens are made by rolling bridge-type perforated steel sheets or plates into cylinders and then seam welding them. Both types offer similar filtration capabilities but differ in their manufacturing techniques.

- What are the advantages of using galvanized bridge slot screens over other materials?

- Galvanized bridge slot screens offer enhanced durability, corrosion resistance, and cost-effectiveness. The galvanized coating provides an additional layer of protection against corrosion, extending the service life of the screens. They are also lighter in weight, making them easier to handle and install. Furthermore, the slot size of galvanized bridge slot screens can be customized to meet specific filtration requirements.

- Can galvanized bridge slot screens be used in high-pressure applications?

- Yes, galvanized bridge slot screens are designed to withstand high pressures. Their special construction and precise slot design enhance their mechanical strength, allowing them to perform effectively in high-pressure environments. The galvanized coating further enhances their resistance to corrosion and pressure.

- Are galvanized bridge slot screens suitable for use in saltwater environments?

- Yes, galvanized bridge slot screens are suitable for use in saltwater environments. The galvanized coating provides excellent corrosion resistance, protecting the screens from the corrosive effects of saltwater. This makes them ideal for applications such as offshore drilling, desalination plants, and coastal water filtration.

- Can galvanized bridge slot screens be customized for specific projects?

- Yes, galvanized bridge slot screens can be customized according to specific project requirements. The slot width, length, wall thickness, and end connections can be tailored to meet the filtration needs of different applications. Customization ensures optimal filtration performance and compatibility with existing systems.

Conclusion:

Galvanized bridge slot screens are highly efficient filtration pipes that offer numerous advantages in terms of durability, corrosion resistance, and cost-effectiveness. Their unique slot design prevents clogging and enhances discharge capacity, making them ideal for various industries such as water well drilling, mining, municipal water supply, refining, water treatment, architecture, and construction. The galvanized coating further enhances their longevity and resistance to corrosion. With their flexible customization options and ability to withstand high pressures, galvanized bridge slot screens are a reliable choice for effective sand control and filtration requirements.