Heavy-Duty “Z” Sheet Piling: A Strong Foundation for Construction Projects

When it comes to constructing structures near bodies of water or in areas with challenging soil conditions, having a strong foundation is crucial. One effective solution for creating a stable foundation is the use of heavy-duty “Z” sheet piling. In this article, we will explore the features, benefits, and applications of heavy-duty “Z” sheet piling, highlighting its importance in construction projects.

What is Heavy-Duty “Z” Sheet Piling?

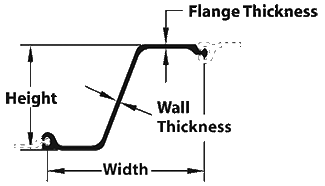

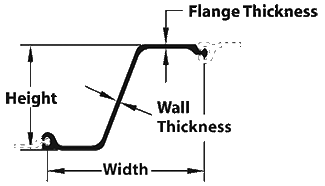

Heavy-duty “Z” sheet piling is a type of interlocking steel sheet pile that is designed to provide exceptional strength and stability in various construction applications. It consists of individual steel sheets that are connected together to form a continuous wall or barrier. The “Z” shape of the sheet pile provides increased strength and stiffness, allowing it to withstand high vertical and horizontal loads.

SPECIFICATIONS

| Section |

PZ 22 |

PZ 27 |

PZ 35 |

PZ 40 |

| Width (in) |

22.0 |

18.0 |

22.6 |

19.7 |

| Height (in) |

9.0 |

12.0 |

14.9 |

16.1 |

| Flange Thickness (in) |

0.375 |

0.375 |

0.600 |

0.600 |

| Web Thickness (in) |

0.375 |

0.375 |

0.500 |

0.500 |

| Area (in2/ft) |

6.47 |

7.94 |

10.29 |

11.77 |

| Pile Weight (lbs/ft) |

40.3 |

40.5 |

66.00 |

65.6 |

| Wall Weight (lbs/ft2) |

22.0 |

27.0 |

35.0 |

40.0 |

| Section Modulus (in3/ft) |

18.1 |

30.2 |

48.5 |

60.7 |

| Moment of Inertia (in4) |

84.38 |

184.20 |

361.22 |

490.85 |

| Coating Area Both Sides (ft2/ft) |

4.48 |

4.48 |

5.37 |

5.37 |

| Coating Area Wall Surface (ft2/ft2) |

1.22 |

1.49 |

1.42 |

1.64 |

Features and Benefits of Heavy-Duty “Z” Sheet Piling

1. Strength and Durability

Heavy-duty “Z” sheet piling is manufactured from high-quality steel, making it incredibly strong and durable. It can withstand heavy loads, including the pressure exerted by soil, water, and other external forces. The strength of the sheet piling ensures the stability and integrity of the structure it supports.

2. Interlocking Design

One of the key features of heavy-duty “Z” sheet piling is its interlocking design. Each sheet pile has interlocking edges that fit together tightly, creating a continuous and watertight barrier. This interlocking mechanism enhances the structural integrity of the sheet piling system, preventing soil erosion and water infiltration.

3. Versatility

Heavy-duty “Z” sheet piling is highly versatile and can be used in a wide range of construction applications. It is commonly used for:

- Retaining walls: Heavy-duty “Z” sheet piling is an excellent choice for constructing retaining walls, especially in areas with soft or loose soil. It provides lateral support and prevents soil movement, ensuring the stability of the structure.

- Cofferdams: In construction projects that require excavation or dewatering, heavy-duty “Z” sheet piling is used to create cofferdams. These temporary structures keep water out of the excavation site, allowing construction activities to take place in a dry environment.

- Flood protection: Heavy-duty “Z” sheet piling is also utilized in flood protection systems. It acts as a barrier to prevent floodwaters from infiltrating critical areas, protecting infrastructure and property from damage.

4. Cost-Effective Solution

Heavy-duty “Z” sheet piling offers a cost-effective solution for construction projects. Its strength and durability eliminate the need for frequent repairs or replacements, resulting in long-term cost savings. Additionally, the ease of installation and removal of sheet piling reduces construction time and labor costs.

These specifications provide valuable information for engineers and contractors when selecting the appropriate heavy-duty “Z” sheet piling for their construction projects. The dimensions, weight, and structural properties of the sheet piling play a crucial role in determining its suitability for specific applications.[/caption]

Applications of Heavy-Duty “Z” Sheet Piling

Heavy-duty “Z” sheet piling finds application in various industries and construction projects, including:

- Marine and waterfront structures: It is commonly used in the construction of docks, piers, seawalls, and bulkheads to provide stability and prevent erosion.

- Bridge abutments and foundations: Heavy-duty “Z” sheet piling is utilized in bridge construction to provide support and stability to abutments and foundations.

- Underground structures: It is used in the construction of underground parking lots, basements, and tunnels to prevent soil movement and water infiltration.

- Environmental protection: Heavy-duty “Z” sheet piling is employed in environmental protection projects, such as land reclamation, shoreline restoration, and erosion control.

Frequently Asked Questions (FAQ)

Q1: How is heavy-duty “Z” sheet piling installed?

A1: Heavy-duty “Z” sheet piling is typically installed using vibratory hammers or hydraulic presses. The sheet piles are driven into the ground sequentially, interlocking with each other to form a continuous wall.

Q2: Can heavy-duty “Z” sheet piling be reused?

A2: Yes, heavy-duty “Z” sheet piling can be reused in certain cases. If the sheet piles are in good condition and meet the required specifications, they can be extracted from one project and used in another.

Q3: What factors should be considered when selecting heavy-duty “Z” sheet piling?

A3: When selecting heavy-duty “Z” sheet piling, factors such as soil conditions, water levels, design requirements, and project specifications should be considered. Consulting with a structural engineer or sheet piling specialist is recommended to ensure the appropriate selection.

Q4: Are there any environmental considerations associated with heavy-duty “Z” sheet piling?

A4: Heavy-duty “Z” sheet piling is made from recyclable steel and has a long lifespan, making it an environmentally friendly choice.A proper installation and maintenance plan should be implemented to minimize any potential environmental impacts.

Q5: Can heavy-duty “Z” sheet piling be used in corrosive environments?

A5: Yes, heavy-duty “Z” sheet piling can be used in corrosive environments. Special coatings or materials can be applied to the sheet piles to enhance their resistance to corrosion, ensuring their longevity and performance.

Conclusion

Heavy-duty “Z” sheet piling is a reliable and versatile solution for creating strong foundations in construction projects. Its interlocking design, strength, and durability make it an ideal choice for various applications, including retaining walls, cofferdams, and flood protection systems. With its cost-effectiveness and environmental benefits, heavy-duty “Z” sheet piling is a preferred option for engineers and contractors. By choosing heavy-duty “Z” sheet piling, construction projects can be built on a solid and stable foundation, ensuring their long-term success.

Remember, when it comes to constructing structures near bodies of water or in challenging soil conditions, heavy-duty “Z” sheet piling is the key to a strong foundation!

Related Posts

ERW piling pipe | ERW Steel Pipe Pile | Welded ERW for Structure

ERW (Electric Resistance Welded) pipe piling is a type of steel pipe that is commonly used in construction and foundation applications, such as in the building of bridges, wharves, and other structures. ERW pipe piling is created by using a process in which a flat steel strip is rolled into a tube shape, and then the edges are heated and welded together using an electric current. ERW pipe piling has a number of advantages over other types of piling, including: Cost-effective: ERW pipe piling is generally less expensive than other types of piling, such as seamless pipe piling. High strength: ERW pipe piling is highly resistant to bending, making it a strong and durable option for foundation applications. Customizable: ERW pipe piling can be manufactured to meet specific size and length requirements, making it highly customizable and adaptable to different project needs.ERW Pipe Piling is available in a range of sizes and thicknesses, and can be produced in lengths of up to 100 feet or more. It is typically made from carbon steel or alloy steel, and can be coated with a layer of protective material to help prevent corrosion and extend the lifespan of the pipe. Versatile: ERW pipe Read more

ASTM A252 Pipe Pile

WELDED Steel Pipe Piles (ERW ,LASW, DSAW ,SSAW.) The two most common methods for steel pipe welding are straight seam or spiral seam welding. Welded steel pipes are typically used to transport fluid (water or oil) and natural gas. It is typically less expensive than seamless steel pipe. Both types of welding are applied after the pipe has been rolled, which involves shaping a sheet of steel into the end shape. Straight Seam: Straight seam welded steel pipes are manufactured by adding a welding parallel to the pipe seam. The process is fairly straightforward: Straight seam pipes are formed when a sheet of steel is bent and formed into a pipe shape, then welded longitudinally. Straight seam pipes can be submerged arc welded (SAW) or double-submerged arc welded (DSAW). Spiral Seam: Spiral seam welded pipes are manufactured when hot-rolled strip steel is formed into a pipe through spiral bending and welded along the then spiraled seam of the pipe. This results in the weld length being 30-100% longer than that of a straight seam welded pipe. This method is more commonly used on large diameter pipe. (Note: this method of welding may also be referred to as helical submerged arc Read more

SSAW Pipe Pile | Spiral Weld Steel Pipe Pilings

Spiral weld pipe pile, otherwise known as SSAW Pipe pile, is a type of pipe piling product used in the construction of deep foundations. It is made from steel that has been formed into a spiral shape and welded together. It is used in a variety of applications, including bridge foundations, retaining walls, deep foundations for buildings, dams, and other large structures. Spiral weld pipe pile is a high-strength, low-alloy steel pipe made from a combination of rolled steel plates and helically wound steel strips. It is highly resistant to corrosion and has a high strength-to-weight ratio, making it an ideal choice for deep foundations and other high-load applications. The process of creating spiral weld pipe pile begins with hot-rolling a steel plate into a coil. This coil is then fed into a machine which shapes it into a spiral shape. This spiral is then cut into sections and welded together to form a single pipe pile. After the welding is complete, the pipe pile is then heat treated and tested to ensure it meets the desired specifications. Spiral weld pipe pile is a strong and reliable choice for any deep foundation or other high-load application. It is resistant to Read more

The technical transition of spiral welded steel pipe piles, ASTM A252, EN10219, AWWA C200

Introduction Steel pipe piles have been used for many years as a foundation element in various construction projects. They are commonly used in the construction of bridges, buildings, and other structures that require a strong and stable foundation. The use of steel pipe piles has evolved over the years, with new technologies and techniques being developed to improve their performance and durability. One of the most significant advancements in the use of steel pipe piles is the transition from traditional steel pipe piles to spiral steel welded pipe piles. This paper will explore the technical transition of steel pipe piles to spiral steel welded pipe piles, including the benefits and challenges associated with this transition. PDF Downloads:Tubular Pile, pipe piles, steel piles, tubular pipes Background Steel pipe piles are typically made from steel plates that are rolled into cylindrical shapes and welded together. They are commonly used in deep foundation applications where the soil conditions are poor or where the structure being built is heavy. Steel pipe piles are typically driven into the ground using a pile driver, which forces the pile into the soil until it reaches a predetermined depth. Once the pile is in place, it provides Read more

ASTM A252 Standard Specification for Welded and Seamless Steel Pipe Piles

Standard Specification for Welded and Seamless Steel Pipe Piles1 This standard is issued under the fixed designation A 252; the number immediately following the designation indicates the year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript epsilon (e) indicates an editorial change since the last revision or reapproval. 1. Scope 1.1 This specification covers nominal (average) wall steel pipe piles of cylindrical shape and applies to pipe piles in which the steel cylinder acts as a permanent load-carrying member, or as a shell to form cast-in-place concrete piles. 1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions of the values in inch-pound units to values in SI units. 1.3 The text of this specification contains notes and footnotes that provide explanatory material. Such notes and footnotes, excluding those in tables and figures, do not contain any mandatory requirements. 1.4 The following precautionary caveat pertains only to the test method portion, Section 16 of this specification. This standard does not purport to address all of the safety problems, if any, associated Read more

Steel Pipe Piles / Steel Pipe Sheet Piles

Steel pipe piles and steel pipe sheet piles have found extensive applications in various construction projects, including ports/harbors, urban civil engineering, bridges, and more. These versatile piles are used in the construction of piers, seawalls, breakwaters, earth-retaining walls, cofferdams, and foundations for steel pipe sheet pile foundations. With the increasing size of structures, deeper water depths, and construction work on sites with deep soft ground, the usage of steel pipe piles and steel pipe sheet piles has expanded significantly.