Trench Sheets: Comprehensive Overview

Introduction

Trench sheets are essential components in civil engineering and construction, particularly for supporting vertical faces of small to medium excavations. They are designed to provide temporary or permanent earth support, ensuring safety and structural integrity during excavation projects. This paper delves into various aspects of trench sheets including their design, materials, installation techniques, applications, and benefits.

Design and Specifications

Trench sheets are typically designed to be lightweight yet strong enough to support vertical soil faces. They come in various profiles and lengths to suit different excavation needs. The design considerations for trench sheets include:

Profiles and Lengths

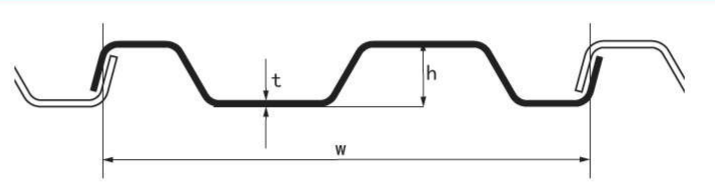

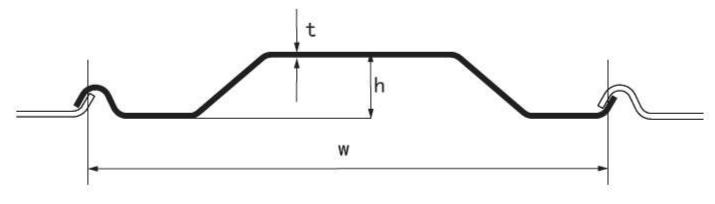

Trench sheets are available in multiple profiles, including:

- Flat Sheets: Simple and easy to handle, suitable for light-duty applications.

- Corrugated Sheets: Offer greater strength and rigidity, suitable for more demanding applications.

Steel Grades

Steel trench sheets are manufactured from various steel grades to meet different strength and durability requirements. Common steel grades include:

- S235: Standard structural steel with good weldability and moderate strength.

- S275: Offers higher strength than S235 and is also easy to weld.

- S355: High-strength steel used for demanding applications where higher load-bearing capacity is required.

Trench Sheeting Catalog

| Section | Dimensions | Mass | Per meter of wall | ||||

| Width | Height | Thickness | Single pile |

Wall | Modulus of Section |

Moment of Inertia |

|

| w | h | t | W | I | |||

| mm | mm | mm | Kg/m | kg/m2 | cm3 | cm4 | |

| GPT600-6 | 600 | 78 | 6 | 37.5 | 62 | 184 | 722 |

| GPT600-7 | 600 | 79 | 7 | 44.5 | 74.1 | 232 | 835 |

| GPT600-8 | 600 | 80 | 8 | 50 | 83 | 237 | 955 |

| GPT600-9 | 600 | 81 | 9 | 55.53 | 92.55 | 263 | 1072 |

| Section | Dimensions | Mass | Moment of inertia | Modulus of Section | |||

| Width | Height | Thickness | Per pile | Wall | |||

| w | h | t | |||||

| mm | mm | mm | kg/m | kg/m2 | cm4/m | cm3/m | |

| GPT 330-3 | 330 | 34 | 3 | 9.72 | 29.45 | 68 | 40 |

| GPT 330-3.5 | 330 | 34.5 | 3.5 | 11.34 | 34.36 | 79 | 46 |

| GPT 330-4 | 330 | 35 | 4 | 12.96 | 39.29 | 91 | 52 |

| GPT 330-4.5 | 330 | 35.5 | 4.5 | 14.53 | 44.04 | 103 | 57 |

| GPT 330-5 | 330 | 36 | 5 | 16.09 | 48.76 | 114 | 63 |

| GPT 400-4 | 400 | 37 | 4 | 15.62 | 39.05 | 100 | 49 |

| GPT 400-5 | 400 | 49 | 5 | 18.52 | 46.3 | 208 | 84 |

| GPT 400-5.5 | 400 | 49.5 | 5.5 | 20.37 | 50.92 | 229 | 91 |

| GPT 400-6 | 400 | 50 | 6 | 22.23 | 55.57 | 250 | 99 |

| GPT 500-5 | 500 | 49 | 5 | 22.45 | 44.9 | 215 | 86 |

| GPT 500-6 | 500 | 50 | 6 | 26.94 | 53.88 | 258 | 101 |

| GPT 742-5 | 742 | 91 | 5 | 33.79 | 45.54 | 745 | 163 |

| GPT 742-6 | 742 | 92 | 6 | 40.9 | 54.66 | 893 | 194 |

| GPT 742-6.5 | 742 | 92.5 | 6.5 | 43.72 | 58.9 | 967 | 209 |

| GPT 742-7 | 742 | 93 | 7 | 47.03 | 63.4 | 1042 | 224 |

| GPT 742-7.5 | 742 | 93.5 | 7.5 | 50.3 | 67.8 | 1116 | 239 |

| GPT 742-8 | 742 | 94 | 8 | 53.56 | 72.18 | 1197 | 254 |

| GPT 742-9 | 742 | 95 | 9 | 60.26 | 81.21 | 1346 | 283 |

| GPT 880-4 | 880 | 152 | 4 | 41.2 | 46.8 | 1897 | 261 |

| GPT 880-6 | 880 | 154 | 6 | 61.9 | 70.3 | 2858 | 382 |

| GPT 880-8 | 880 | 156 | 8 | 84.6 | 96.1 | 3890 | 510 |

Note: This table is only part of our sizes. We have over 1000 different sizes. We can adjust our machine to produce in any width,Height and thickness. Please contact us if your size is not in above table.

Overlapping and Interlocking

Trench sheets can be either overlapping or interlocking:

- Overlapping Trench Sheets: These do not have interlocks and are placed adjacent to each other with a slight overlap. This method is simpler and quicker but may require additional sealing to prevent soil and water ingress.

- Interlocking Trench Sheets: These have interlocking edges that connect to form a continuous barrier, providing better soil and water retention.

Installation Techniques

The installation of trench sheets involves several steps and specialized equipment to ensure proper placement and safety:

Equipment

- Excavators with Quick Release Shackle: Used for handling and positioning trench sheets through slinging holes at the ends of the sheets.

- Driving Cap: Protects the trench sheets from damage during driving by distributing the impact force evenly.

- Extraction Clamps: Used to safely remove trench sheets without causing deformation.

Installation Process

- Site Preparation: Clear the excavation site and mark the trench lines.

- Sheet Handling: Use excavators with quick release shackles to position the trench sheets.

- Driving Sheets: Drive the trench sheets into the ground using a driving cap. Ensure alignment and proper overlap or interlock.

- Sealing Joints: If using overlapping sheets, apply sealant to prevent soil and water ingress.

- Bracing and Support: Install any necessary bracing to maintain trench stability.

- Extraction: After excavation work is completed, use extraction clamps to safely remove the trench sheets for reuse.

Applications

Trench sheets are versatile and find applications in various construction and civil engineering projects:

Pipeline Installation

Trench sheets are commonly used to support excavations for pipeline installations. Their lightweight design and ease of reuse make them ideal for this application.

Earth Retention

In construction projects, trench sheets provide temporary support for vertical soil faces, preventing collapse and ensuring worker safety.

Waterway Banks

Due to their strength, speed of installation, and flexibility, trench sheets are often used to support waterway banks, preventing erosion and maintaining structural integrity.

Urban Excavations

In urban environments, trench sheets are used to support excavations for utilities, foundations, and other infrastructure projects, minimizing disruption and ensuring safety.

Advantages

Trench sheets offer several advantages that make them a preferred choice in many construction projects:

Strength and Durability

Manufactured from high-quality steel, trench sheets provide excellent strength and durability, capable of withstanding significant loads and harsh environmental conditions.

Speed of Installation

The lightweight design and simple handling procedures allow for quick and efficient installation, reducing project timelines and costs.

Flexibility

Trench sheets can be easily adapted to various profiles and lengths, making them suitable for a wide range of applications. Their ability to be reused multiple times further enhances their flexibility and cost-effectiveness.

Reusability

Trench sheets can be extracted and reused multiple times without significant deformation, making them a sustainable and economical choice for construction projects.

Safety

By providing reliable earth support, trench sheets enhance safety on construction sites, protecting workers and ensuring structural stability during excavation activities.

Regional Popularity

Trench sheets are especially popular in regions with softer soils, such as the Middle East and Australia. In these areas, the soil conditions allow for easier driving and extraction of trench sheets, making them an ideal solution for various excavation projects.

Design and Calculation Services

To ensure optimal performance and cost-effectiveness, comprehensive design and calculation services are available for trench sheet projects. These services include:

- Trench Sheeting Design: Customized design solutions tailored to specific project requirements.

- Load Calculations: Detailed calculations to ensure the trench sheets can support the expected loads.

- Cost Estimations: Accurate cost estimations to help clients budget their