Why Are High Standards Essential for Piling Pipe Suppliers?

Introduction

Piling pipes are critical components in construction and infrastructure projects, providing foundational support and stability to structures such as bridges, buildings, and offshore platforms. Given their crucial role, it is imperative for piling pipe suppliers to adhere to high standards of quality and performance. This article explores the reasons why high standards are essential for piling pipe suppliers, highlighting the impact on safety, durability, and project success.

The Role of Piling Pipes in Construction

Foundation Support

Piling pipes are used to transfer the load of a structure to a stable soil layer or bedrock, ensuring the foundation’s stability and integrity. They are driven deep into the ground, providing support and preventing settlement or shifting.

Versatility

Piling pipes are versatile and can be used in various soil conditions and environments, including soft soils, waterlogged areas, and seismic zones. They are suitable for a wide range of applications, from residential buildings to large-scale infrastructure projects.

Load-Bearing Capacity

The load-bearing capacity of piling pipes is a critical factor in determining the overall stability and safety of a structure. High-quality piling pipes are designed to withstand significant loads and pressures, ensuring the structure’s longevity and performance.

Importance of High Standards for Piling Pipe Suppliers

Ensuring Safety and Reliability

Structural Integrity

High standards in manufacturing and quality control ensure that piling pipes possess the necessary structural integrity to support the intended loads. This minimizes the risk of failure or collapse, protecting both the structure and its occupants.

Compliance with Regulations

Piling pipe suppliers must adhere to industry standards and regulations to ensure safety and reliability. Compliance with standards such as ASTM, ISO, and EN ensures that the pipes meet the required specifications for strength, durability, and performance.

Enhancing Durability and Longevity

Material Quality

The quality of materials used in piling pipes directly impacts their durability and longevity. High standards ensure that suppliers use premium materials, such as high-strength steel, that can withstand environmental factors and resist corrosion.

Advanced Manufacturing Techniques

Adopting advanced manufacturing techniques, such as seamless pipe production and precision welding, enhances the quality and performance of piling pipes. High standards ensure that suppliers utilize the latest technologies to produce reliable and durable products.

Supporting Project Success

Cost-Effectiveness

High-quality piling pipes reduce the risk of structural issues and costly repairs, contributing to the overall cost-effectiveness of a project. By investing in high standards, suppliers help ensure that projects are completed on time and within budget.

Reputation and Trust

Adhering to high standards builds trust and credibility with clients and stakeholders. Piling pipe suppliers with a reputation for quality and reliability are more likely to secure contracts and maintain long-term partnerships.

Challenges in Maintaining High Standards

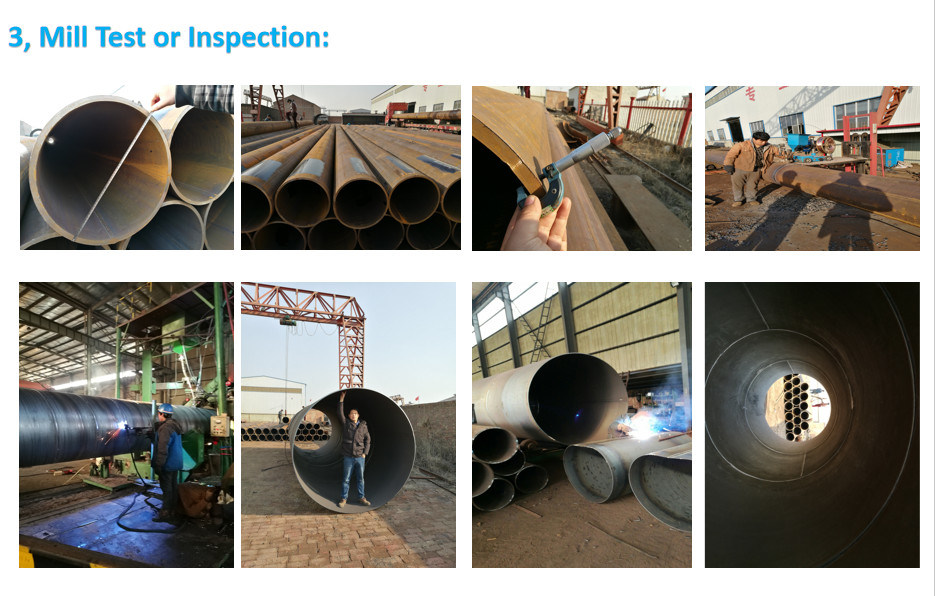

Quality Control and Assurance

Implementing rigorous quality control and assurance processes is essential for maintaining high standards. This involves regular inspections, testing, and certification to ensure that piling pipes meet the required specifications.

Technological Advancements

Staying abreast of technological advancements and industry trends is crucial for maintaining high standards. Piling pipe suppliers must invest in research and development to adopt new materials, techniques, and technologies that enhance product quality.

Supply Chain Management

Effective supply chain management is vital for ensuring the consistent quality of piling pipes. Suppliers must work closely with material providers, manufacturers, and logistics partners to maintain high standards throughout the production and delivery process.

Conclusion

High standards are essential for piling pipe suppliers to ensure the safety, reliability, and success of construction and infrastructure projects. By adhering to stringent quality and performance standards, suppliers contribute to the structural integrity and longevity of the built environment. As the demand for robust and durable foundations continues to grow, maintaining high standards will remain a critical priority for piling pipe suppliers.

FAQ

1. What is the primary role of piling pipes in construction?

Piling pipes provide foundational support and stability to structures, transferring the load to a stable soil layer or bedrock and preventing settlement or shifting.

2. Why are high standards important for piling pipe suppliers?

High standards ensure safety, reliability, durability, and project success by ensuring structural integrity, compliance with regulations, and the use of quality materials and manufacturing techniques.

3. How do high standards enhance the durability and longevity of piling pipes?

High standards ensure the use of premium materials and advanced manufacturing techniques, resulting in piling pipes that can withstand environmental factors and resist corrosion.

4. What challenges do piling pipe suppliers face in maintaining high standards?

Challenges include implementing rigorous quality control and assurance processes, staying abreast of technological advancements, and managing the supply chain effectively.

5. How do high standards contribute to project success?

High-quality piling pipes reduce the risk of structural issues and costly repairs, contributing to cost-effectiveness and building trust and credibility with clients and stakeholders.