Emerging Trends in the Steel Pipe Industry for 2025: A Glimpse into the Future

Introduction

The steel pipe industry is a critical component of global infrastructure, playing a vital role in sectors such as construction, energy, and transportation. As we approach 2025, the industry is poised for significant transformation, driven by technological advancements, environmental considerations, and evolving market demands. This article explores the emerging trends that are set to shape the steel pipe industry in 2025, offering insights into the future of this dynamic sector.

Technological Advancements

Smart Manufacturing

The integration of smart manufacturing technologies is revolutionizing the steel pipe industry. By leveraging the Internet of Things (IoT), artificial intelligence (AI), and data analytics, manufacturers can optimize production processes, enhance quality control, and reduce waste. Smart manufacturing enables real-time monitoring and predictive maintenance, leading to increased efficiency and cost savings.

Advanced Materials

The development of advanced materials is another key trend in the steel pipe industry. Researchers are exploring new alloys and coatings that offer superior strength, corrosion resistance, and durability. These materials are designed to withstand harsh environments and extend the lifespan of steel pipes, making them ideal for demanding applications such as offshore drilling and chemical processing.

Environmental Sustainability

Green Manufacturing Practices

As environmental concerns continue to rise, the steel pipe industry is adopting green manufacturing practices to reduce its carbon footprint. This includes the use of energy-efficient technologies, recycling of scrap materials, and the implementation of sustainable supply chain practices. Companies are also investing in renewable energy sources to power their operations, further minimizing their environmental impact.

Eco-Friendly Products

In response to growing demand for sustainable solutions, manufacturers are developing eco-friendly steel pipe products. These products are designed to be fully recyclable and are produced using environmentally responsible methods. The focus on sustainability is not only beneficial for the environment but also aligns with the values of environmentally conscious consumers and businesses.

Market Dynamics

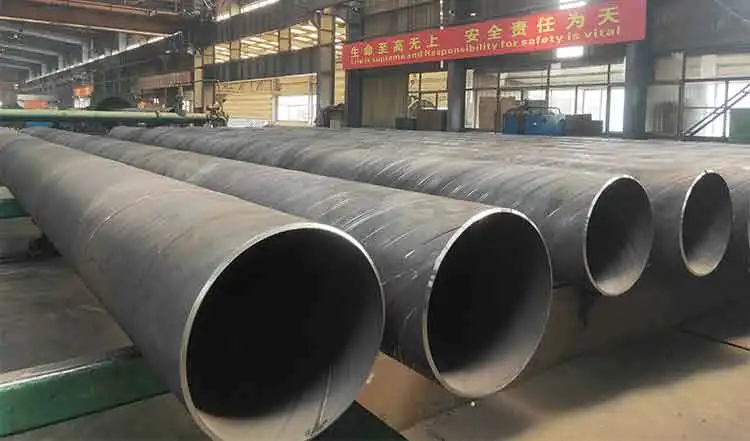

Increasing Demand for Infrastructure Development

The global push for infrastructure development is driving demand for steel pipes. Emerging economies are investing heavily in infrastructure projects, including transportation networks, water supply systems, and energy pipelines. This trend is expected to continue, providing significant growth opportunities for the steel pipe industry.

Shift Towards Renewable Energy

The transition to renewable energy sources is reshaping the steel pipe industry. As countries strive to reduce their reliance on fossil fuels, there is an increasing need for steel pipes in renewable energy projects such as wind farms, solar power plants, and hydrogen production facilities. This shift presents new challenges and opportunities for manufacturers to innovate and adapt to changing market demands.

Regulatory and Compliance Considerations

Stricter Environmental Regulations

Governments worldwide are implementing stricter environmental regulations to combat climate change and protect natural resources. The steel pipe industry must comply with these regulations, which may require investments in cleaner technologies and sustainable practices. Companies that proactively address regulatory requirements will be better positioned to succeed in the evolving market landscape.

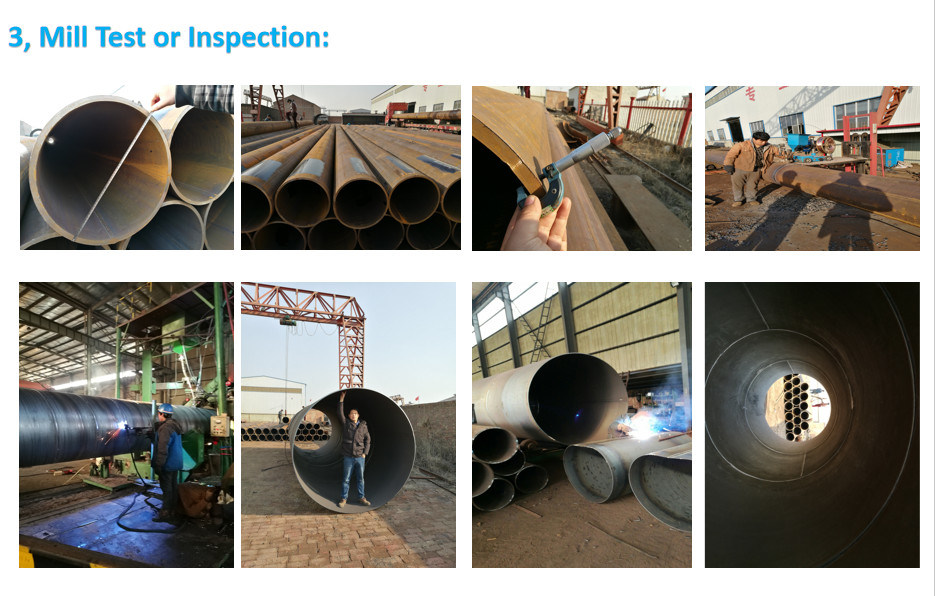

Quality and Safety Standards

As the industry evolves, there is a growing emphasis on quality and safety standards. Manufacturers must adhere to rigorous standards to ensure the reliability and safety of their products. This includes implementing robust quality control measures and obtaining relevant certifications to meet customer and regulatory expectations.

FAQ

What are the key technological advancements in the steel pipe industry for 2025?

Smart manufacturing technologies, such as IoT, AI, and data analytics, are optimizing production processes, while advanced materials offer superior strength and durability.

How is the steel pipe industry addressing environmental sustainability?

The industry is adopting green manufacturing practices, developing eco-friendly products, and investing in renewable energy sources to reduce its carbon footprint.

What market dynamics are influencing the steel pipe industry?

Increasing demand for infrastructure development and the shift towards renewable energy are driving growth and innovation in the industry.

What regulatory considerations must the steel pipe industry address?

The industry must comply with stricter environmental regulations and adhere to quality and safety standards to meet customer and regulatory expectations.

How can manufacturers succeed in the evolving steel pipe industry?

By embracing technological advancements, prioritizing sustainability, and adapting to changing market demands, manufacturers can position themselves for success in the future.