Stainless Steel 304 V-Wire Wedge Water Well Sand Johnson Screen: A Detailed Overview

Introduction

Stainless steel 304 V-wire wedge water well sand screens, commonly referred to as Johnson screens, are essential components in water well filtration systems. These screens are designed to filter out sand, gravel, and other sediments while allowing water to flow freely into the well. The unique V-wire design ensures that the screen remains unclogged, providing optimal water flow and long-lasting performance.

The V-wire wedge design consists of a V-shaped profile wire wrapped around longitudinal support rods. Each intersection point is fusion welded, creating a durable structure that can withstand the high pressures and mechanical stresses encountered in deep wells. The continuous slot design provides a larger open area, reducing the speed of water entering the well and preventing sand from being drawn in under high pressure.

This article will provide a comprehensive overview of stainless steel 304 V-wire wedge water well sand screens, including their design, advantages, applications, and selection criteria.

Quick details of wire point pipe:

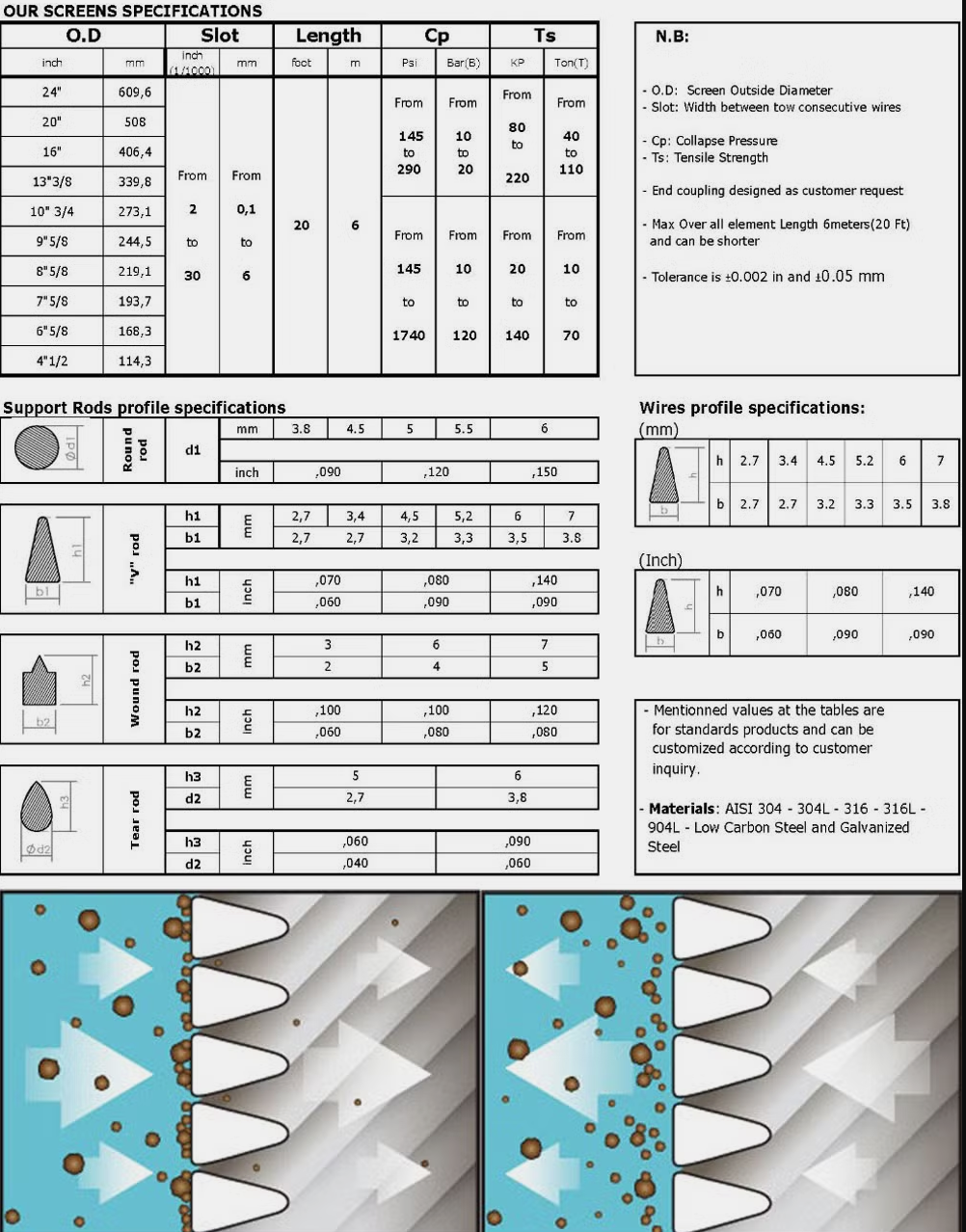

| Name | Stainless Steel 304 V-Wire Wedge Water Well Sand Johnson Screen |

| Material | Stainless steel 304, 304L, 316, 316L, Carbon steel, low carbon steel, low carbon galvanized steel |

| Open area | Up to 60% |

| Slot size | 0.0.2mm~15.00mm |

| Diameter | 25mm to 1500mm |

| Length | <6 meters |

| Application | water purification |

| End Finishing | Thread fitting, Flange, Closed Plated, Metal Ring, etc |

Remark: Customized According To Requirement.

| SIZE (INCH) |

O.D (MM) |

SLOT (INCH) |

LENGTH (M) |

COLLAPSE STRENGTH (PSI) |

TENSILE WEIGHT (TON) |

WRAP(thick*deep) (MM) |

RODS (MM) |

| 4 | 117 | 0.040 | 3 | 395 | 6 | 2.2*3.0 | 3.8MM/22 |

| 4 | 114.3 | 0.040 | 3 | 395 | 6 | 2.3*3.0 | 3.8MM/22 |

| 6 | 168.3 | 0.040 | 3 | 252 | 8 | 2.3*3.5 | 3.8MM/32 |

| 8 | 219.1 | 0.010 | 3 | 399 | 10.5 | 3.0*5.0 | 3.8MM/48 |

| 8 | 219.1 | 0.020 | 3 | 370 | 10.5 | 3.0*5.0 | 3.8MM/48 |

| 8 | 219.1 | 0.040 | 3 | 323 | 10.5 | 3.0*5.0 | 3.8MM/48 |

| 10 | 273.1 | 0.010 | 3 | 206 | 11 | 3.0*5.0 | 3.8MM/50 |

| 10 | 273.1 | 0.020 | 3 | 191 | 11 | 3.0*5.0 | 3.8MM/50 |

| 10 | 273.1 | 0.040 | 3 | 167 | 11 | 3.0*5.0 | 3.8MM/50 |

Table of Contents

- What Is a Stainless Steel 304 V-Wire Wedge Water Well Sand Screen?

- How Does a V-Wire Wedge Water Well Screen Work?

- Advantages of Stainless Steel 304 V-Wire Wedge Screens

- Applications of Johnson Screens

- Materials Used in V-Wire Wedge Screens

- How to Select the Right Stainless Steel 304 V-Wire Screen

- Installation and Maintenance

- Frequently Asked Questions (FAQ)

- Conclusion

What Is a Stainless Steel 304 V-Wire Wedge Water Well Sand Screen? {#what-is-a-stainless-steel-304-v-wire-wedge-water-well-sand-screen}

A stainless steel 304 V-wire wedge water well sand screen is a type of well screen used in water wells to filter out sand and sediment while allowing water to flow into the well. The screen is constructed using a V-shaped profile wire that is wrapped around longitudinal support rods. Each point where the wires intersect is fusion welded, creating a strong and durable structure.

The V-shaped wire is designed to prevent blockage by allowing debris to slide off the screen, ensuring that water can flow freely into the well. The continuous slot design provides a larger open area, which reduces the speed of water entering the pipe and helps prevent sand from being drawn into the well under high pressure.

Stainless steel 304 is a popular material for these screens due to its excellent corrosion resistance, durability, and cost-effectiveness. It is widely used in water wells, oil and gas wells, and geothermal wells where corrosion resistance is critical.

How Does a V-Wire Wedge Water Well Screen Work? {#how-does-a-v-wire-wedge-water-well-screen-work}

The V-wire wedge water well screen works by using its V-shaped profile wire and continuous slot design to filter out sand and sediment while allowing water to flow into the well. Here’s how it works:

1. V-Shape Profile Wire

The V-shaped wire is designed to prevent blockage by allowing particles to slide off the screen. This ensures that the screen remains unclogged and that water can flow freely into the well.

2. Continuous Slot Design

The continuous slot between the wires provides a larger open area, which allows more water to enter the well at a lower velocity. This reduces the pressure on the screen and helps prevent sand from being drawn into the well.

3. Fusion Welding

At each intersection point of the profile wire and the support rods, the wires are fusion welded. This creates a strong and durable structure that can withstand the mechanical stresses and high pressures encountered in deep wells.

4. Slot Size Customization

The slot size of the screen can be customized based on the grain size of the surrounding formation. This ensures that the screen provides the right level of filtration for the specific geological conditions of the well.

Advantages of Stainless Steel 304 V-Wire Wedge Screens {#advantages-of-stainless-steel-304-v-wire-wedge-screens}

Stainless steel 304 V-wire wedge water well screens offer several advantages over other types of well screens. These advantages include:

1. Prevents Blockage

The V-shaped profile wire is designed to prevent blockage by allowing debris to slide off the screen. This ensures that the screen remains unclogged and that water can flow freely into the well.

2. High Open Area

The continuous slot design provides a larger open area, which allows more water to enter the well at a lower velocity. This reduces the risk of sand entering the well and helps maintain high flow rates.

3. Durability

The fusion welding at each intersection point of the wires creates a strong and durable structure that can withstand the mechanical stresses and high pressures encountered in deep wells.

4. Corrosion Resistance

Stainless steel 304 offers excellent corrosion resistance, making it ideal for use in aggressive groundwater environments or saltwater wells. This ensures that the screen has a long service life, even in harsh conditions.

5. Customizable Slot Size

The slot size of the screen can be customized based on the grain size of the surrounding formation. This ensures that the screen provides the right level of filtration for the specific geological conditions of the well.

6. Improved Well Efficiency

By reducing the speed of water entering the well and preventing sand from being drawn into the well, stainless steel 304 V-wire wedge screens help improve the overall efficiency and longevity of the well.

Applications of Johnson Screens {#applications-of-johnson-screens}

Stainless steel 304 V-wire wedge screens, also known as Johnson screens, are used in a variety of applications, including:

1. Water Wells

Johnson screens are widely used in municipal water wells, irrigation wells, and industrial water supply wells. The screens provide effective filtration, ensuring that clean water enters the well while preventing sand and sediment from clogging the well.

2. Oil and Gas Wells

In the oil and gas industry, Johnson screens are used to filter out sand and gravel while allowing oil, gas, or water to flow into the well. The screens are designed to withstand the high pressures and corrosive environments typically found in oil and gas fields.

3. Geothermal Wells

Johnson screens are used in geothermal wells to filter out sediments while allowing geothermal fluids to flow into the well. The screens must be able to withstand the high temperatures and corrosive conditions found in geothermal environments.

4. Environmental Monitoring Wells

Johnson wedge wire screens are used in environmental monitoring wells to sample groundwater and monitor contamination levels. The screens ensure that the samples are free from sediment contamination, providing accurate data for environmental assessments.

5. Water Treatment Systems

In water treatment plants, Johnson wedge wire screens are used to filter out sediments and debris from water before it is treated. The screens help improve the efficiency of the treatment process by preventing clogging and ensuring uninterrupted water flow.

Materials Used in V-Wire Wedge Screens {#materials-used-in-v-wire-wedge-screens}

While stainless steel 304 is the most commonly used material for V-wire wedge screens, other materials may be used depending on the application and environmental conditions.

1. Stainless Steel 304

Stainless steel 304 is a popular material for V-wire wedge screens due to its excellent corrosion resistance, durability, and cost-effectiveness. It is widely used in water wells, oil and gas wells, and geothermal wells.

2. Stainless Steel 316

For more corrosive environments, such as saltwater wells or geothermal wells, stainless steel 316 may be used. Stainless steel 316 offers higher corrosion resistance due to its molybdenum content, making it ideal for use in aggressive environments.

3. Carbon Steel

In less corrosive environments where cost is a concern, carbon steel may be used. While carbon steel does not offer the same level of corrosion resistance as stainless steel, it is still a durable and cost-effective option for many applications.

How to Select the Right Stainless Steel 304 V-Wire Screen {#how-to-select-the-right-stainless-steel-304-v-wire-screen}

Selecting the right stainless steel 304 V-wire wedge screen for your well requires careful consideration of several factors, including:

1. Slot Size

The slot size should be based on the grain size of the surrounding formation. A sieve analysis can help determine the appropriate slot size to ensure efficient filtration and prevent sand from entering the well.

2. Material Selection

The choice of material depends on the corrosiveness of the well environment. Stainless steel 304 is recommended for wells with moderate corrosiveness, while stainless steel 316 may be required for more aggressive environments.

3. Well Depth and Pressure

Deeper wells are subject to higher pressures, so it is important to choose a well screen with sufficient strength and collapse resistance. Thicker-walled screens or high-strength materials may be required for deep wells.

4. Flow Rate Requirements

The open area of the screen will affect the flow rate of the well. Continuous slot designs offer higher open areas and are ideal for wells with high flow rate requirements.

Installation and Maintenance {#installation-and-maintenance}

Installation

Proper installation of stainless steel 304 V-wire wedge screens is critical to ensuring their performance and longevity. The screen should be installed at the correct depth, with the slots oriented to maximize water flow from the aquifer. In some cases, a gravel pack may be used around the screen to enhance filtration and prevent clogging.

Maintenance

Regular inspection and maintenance of the well screen are important to ensure optimal performance. Over time, the screen may become clogged with sediment or biofilm, reducing the flow rate. Jetting, brushing, or chemical treatments can be used to clean the screen and restore its functionality.

Frequently Asked Questions (FAQ) {#faq}

1. What is the purpose of a stainless steel 304 V-wire wedge screen?

A stainless steel 304 V-wire wedge screen is used to filter out sand, gravel, and other sediments while allowing water or fluids to flow into the well. It helps prevent clogging and protects the pumping equipment from damage.

2. Why is the V-shaped wire important in V-wire wedge screens?

The V-shaped wire is important because it prevents blockage by allowing debris to slide off the screen. This ensures that the screen remains unclogged and that water can flow freely into the well.

3. How do I choose the right slot size for my V-wire wedge screen?

The slot size should be based on the grain size of the surrounding formation. A sieve analysis of the formation material can help determine the appropriate slot size to ensure efficient filtration and flow.

4. Can stainless steel 304 V-wire wedge screens be used in saltwater wells?

Yes, stainless steel 304 offers good corrosion resistance and can be used in saltwater wells. However, for more aggressive environments, stainless steel 316 may be a better option due to its higher chloride resistance.

5. How often should a stainless steel 304 V-wire wedge screen be cleaned?

The frequency of cleaning depends on the well conditions and the amount of sediment in the water. Regular inspections can help determine when cleaning is necessary.

Conclusion {#conclusion}

Stainless steel 304 V-wire wedge water well sand screens are a critical component in water wells and water treatment systems, providing effective filtration and ensuring uninterrupted water flow. Their V-shaped profile wire and continuous slot design make them highly efficient at preventing blockage and filtering out sand and sediment.