Sheet piling offers several advantages in various construction and civil engineering applications. Here are some of the key advantages of sheet piling:

- Efficient Earth Retention: Sheet piles provide effective earth retention and excavation support, allowing for safe and stable construction in areas with challenging soil conditions. They resist lateral soil pressure and prevent soil movement, minimizing the risk of slope failures and cave-ins.

- Versatility: Sheet piles are available in a variety of shapes, sizes, and materials, making them versatile for different project requirements. They can be easily interlocked and installed in various configurations, allowing for flexibility in design and adaptability to different site conditions.

- Strength and Durability: Steel sheet piles, in particular, offer high strength and durability, making them suitable for demanding applications. They can withstand heavy loads and harsh environmental conditions, such as water, corrosion, and impact forces.

- Rapid Installation: Sheet piles can be installed quickly and efficiently, which is beneficial for projects with tight schedules. They can be driven into the ground using vibratory hammers or hydraulic presses, reducing construction time and labor costs.

- Reusability: Steel sheet piles can be extracted and reused in other projects, providing a sustainable and cost-effective solution. This makes them environmentally friendly and reduces the need for new materials.

- Water Resistance: Sheet piles can be used to create watertight barriers, such as cofferdams and flood control structures. They prevent water seepage and protect against erosion, helping to safeguard construction sites and adjacent areas.

- Noise and Vibration Control: Sheet piling installation techniques, such as the use of vibratory hammers, minimize noise and vibration levels compared to other construction methods. This is particularly advantageous in urban areas or projects near sensitive structures.

- Aesthetics: Sheet piles can be designed to have an aesthetic appearance, especially in waterfront developments or landscaping projects. Options for surface treatments and coatings allow for customization to meet specific design requirements.

It’s important to note that the selection of sheet piling and its advantages may vary depending on project-specific factors, such as soil conditions, water levels, design loads, and environmental considerations. Consulting with a qualified engineer or contractor is recommended to assess the suitability and benefits of sheet piling for a particular project.

Sheet piles and H-piles are two common types of structural sections used in construction and civil engineering projects. Here’s a breakdown of the information provided:

- Sheet Piles:

- Carbon Steel Cold-Rolled Sheet Pile: These are new sheets manufactured in the USA. They are available in various types, including light-weight and heavy Z-type sheets. The production can be customized to the desired length with a quick turnaround time.

- Carbon Steel Hot-Rolled Sheet Pile: These sheets can be both new and used and are manufactured in the USA and offshore. They are available in different types, including Z sheets (PZ22, PZ27, PZ35, PZ40) and flat web sheets (YSP-FXL, PS31). Flat web sheets are suitable for circular cells. Standard specifications offered are ASTM A572 Grade 50 and ASTM A328.

- H-Piles:

- Carbon Steel H-Pile: These piles are manufactured in the abtersteel Inc. They offer a complete line of H-piles with different foot weights and lengths, including HP10 X 42, HP10 X 57, HP12 X 53, HP12 X 74, HP14 X 73, HP14 X 89, HP14 X 102, and HP14 X 117. The products are available in ASTM A-992 or ASTM A572 Grade 50 specifications. Standard stocking lengths are 40′, 50′, and 60′. The finishes are bare.

It’s important to note that sheet piles are primarily used for earth retention and excavation support, while H-piles are commonly used for deep foundation applications, such as pile driving and load-bearing structures. The choice between sheet piles and H-piles depends on the specific project requirements and soil conditions. Consulting with a qualified engineer or contractor is recommended to determine the most suitable option for a particular project.

The U Hot Rolled Steel Sheet Piles offer several advantages, including:

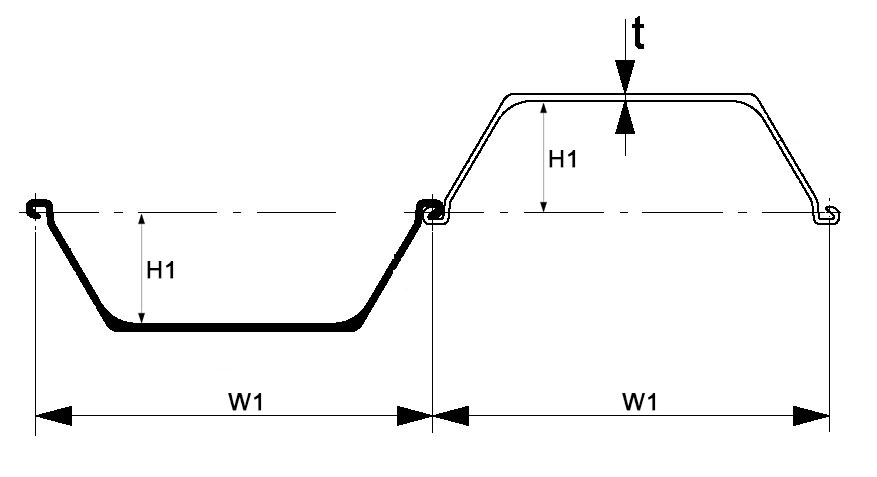

Wide Range of Sections: The U Hot Rolled Steel Sheet Piles are available in various series with different geometrical characteristics. This wide range allows for a technically and economically optimal choice based on the specific project requirements.

Excellent Statical Properties: These sheet piles have a combination of significant profile depth and large flange thickness, resulting in excellent statical properties. This enhances their load-bearing capacity and structural performance.

Convenient for Re-use: The symmetrical form of the single element makes U Hot Rolled Steel Sheet Piles suitable for re-use. This feature allows for cost savings and environmental sustainability by enabling the piles to be dismantled, relocated, and used in future projects.

Improved Installation Quality: The possibility of assembling and crimping the sheet piles into pairs at the mill enhances the installation quality and performance. This ensures better alignment, stability, and overall construction efficiency.

Easy Fixing of Tie-Rods and Attachments: U Hot Rolled Steel Sheet Piles facilitate easy fixing of tie-rods and swivelling attachments, even underwater. This convenience simplifies the installation process and provides flexibility for additional structural elements or accessories.

Good Corrosion Resistance: The steel used in U Hot Rolled Steel Sheet Piles is thickest at critical corrosion points, offering good corrosion resistance. This helps to prolong the lifespan of the sheet piles, especially in marine or corrosive environments.

Overall, U Hot Rolled Steel Sheet Piles provide a versatile and efficient solution for earth retention, excavation support, and various construction projects. Their advantages encompass technical, economic, and practical aspects, making them a preferred choice in many applications.