Analysis of Soil Strength Degradation Around Large-Diameter Steel Pipe Piles During Driving

1. Introduction

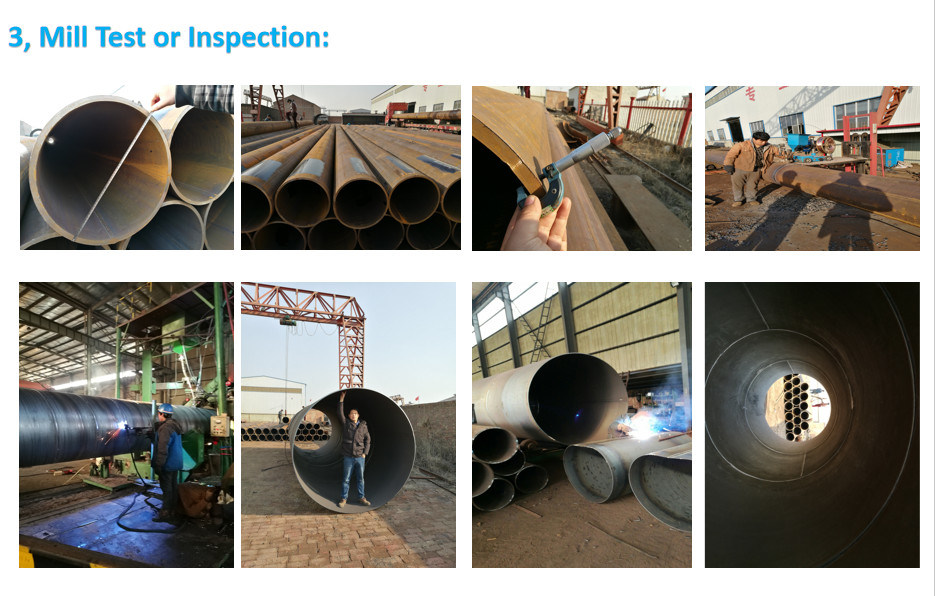

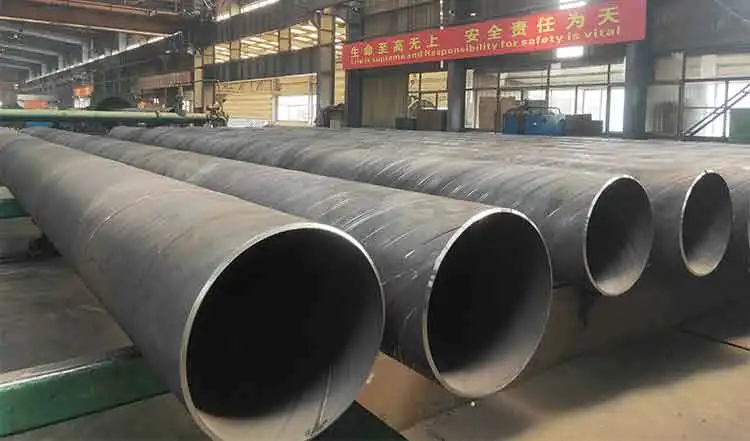

Large-diameter steel pipe piles (typically exceeding 48 inches in diameter) are critical in modern infrastructure, such as offshore platforms, high-rise buildings, and bridges, due to their high load-bearing capacity, lateral resistance, and adaptability to diverse geotechnical conditions . However, during pile driving, the surrounding soil undergoes significant strength degradation, which affects the short-term drivability and long-term performance of the foundation. This phenomenon arises from dynamic soil-pile interactions, including pore pressure buildup, soil remolding, and thixotropic effects . Understanding these mechanisms is essential for optimizing pile design, mitigating risks, and ensuring structural integrity.

2. Mechanisms of Soil Strength Degradation

2.1 Pore Water Pressure Development

During driving, rapid shearing of soil particles generates excess pore water pressure, particularly in low-permeability soils like clays. This reduces effective stress and shear strength, leading to temporary liquefaction in saturated sands or undrained strength loss in cohesive soils . For example, in offshore wind turbine foundations, lateral friction resistance decreases by up to 30–50% during high-energy hammer impacts due to pore pressure accumulation .

2.2 Soil Remolding and Structural Disruption

The mechanical disturbance from pile penetration remolds the soil matrix, breaking particle bonds and reorienting grains. In clays, this causes a reduction in undrained shear strength (up to 50% within a zone extending 2× pile diameter from the shaft) . Ring shear tests simulating pile driving in marine clays show that shear strength decreases exponentially with increasing shear rate, reflecting strain-softening behavior .

2.3 Thixotropy and Time-Dependent Recovery

Post-driving, remolded soils regain strength over time through thixotropic reorientation of particles and pore pressure dissipation. For instance, reconsolidated clays around driven piles may exhibit shear strengths exceeding their original undisturbed values due to increased effective stress . This recovery is critical for long-term shaft capacity but complicates short-term drivability predictions .

3. Key Influencing Factors

3.1 Pile Diameter and Mass

Larger-diameter piles induce broader stress fields, amplifying soil disturbance. Model tests on offshore wind piles reveal that lateral friction degradation scales with pile diameter, as larger masses displace more soil and generate higher pore pressures . For example, a 2.5 m diameter pile caused 40% greater strength reduction than a 1.5 m pile under identical hammer energy .

3.2 Soil Type and Drainage Conditions

- Clayey Soils: High sensitivity to remolding and slow pore pressure dissipation lead to pronounced short-term strength loss.

- Sandy Soils: Rapid drainage minimizes pore pressure effects, but cyclic shearing can densify loose sands, increasing lateral resistance post-driving .

- Intermediate Soils (Silts): Exhibit mixed behavior, with partial pore pressure buildup and moderate remolding effects .

3.3 Hammer Energy and Driving Technique

High-energy impact hammers exacerbate soil degradation by increasing shear strain rates. Vibratory driving, while reducing noise and vibration, may cause less remolding due to lower peak stresses . Field data from offshore projects show that hammer energies exceeding 400 kJ/m³ correlate with >50% reductions in near-pile shear strength .

3.4 Pile Length and Installation Depth

Long piles in soft clays experience progressive strength degradation along the shaft due to repeated shearing of the same soil layers. API guidelines note that “pile whip” (lateral oscillations during driving) can displace soil laterally, further reducing shaft resistance .

4. Numerical Modeling of Pile-Soil Interaction

4.1 Finite Element Analysis (FEA)

Advanced 3D FEA models (e.g., ABAQUS) simulate soil-pile contact using penalty-based algorithms and nonlinear soil constitutive laws (e.g., Mohr-Coulomb, Modified Cam-Clay). These models capture stress redistribution, pore pressure evolution, and strain localization around the pile . For instance, simulations of laterally loaded piles in sand show that soil modulus and friction angle significantly influence bending moment distributions .

4.2 Subgrade Reaction and p-y Curves

The Winkler spring model simplifies soil response using p-y curves to represent lateral soil resistance. While less computationally intensive, it ignores continuum effects and is less accurate for large-diameter piles under combined axial-lateral loading . Hybrid approaches, such as coupling p-y springs with FEA, improve predictions for offshore monopiles subjected to cyclic wave loads .

4.3 Wave Equation Analysis (WEAP)

WEAP predicts driving stresses and soil resistance using stress wave theory. It is particularly effective for granular soils, where damping and quake parameters can be calibrated via CAPWAP® signal matching . For example, CAPWAP analyses of restrike tests in clays have quantified setup effects, showing 2–3× increases in shaft capacity over 30 days .

5. Case Studies and Field Observations

5.1 Offshore Wind Turbine Foundations

Field measurements from Chinese offshore wind projects demonstrate that soil strength degradation during driving is proportional to both pile mass and hammer energy. A degradation formula derived from ring shear tests was integrated into piling software, reducing prediction errors by 15–20% .

5.2 Liquefaction-Induced Pile Failures

In the 2011 Tohoku earthquake, piles in liquefied sands experienced buckling and settlement due to loss of lateral support. Post-liquefaction reconsolidation increased shaft friction but caused differential settlements exceeding 200 mm in some cases .

5.3 Corrosion and Long-Term Degradation

Acidic soils accelerate steel pile corrosion, reducing cross-sectional area and adhesion at the pile-soil interface. Model tests show that corroded piles exhibit 20–30% higher settlements due to weakened skin friction .

6. Monitoring and Mitigation Strategies

6.1 Real-Time Dynamic Monitoring

- Pile Driving Analyzer (PDA): Measures force and velocity waves to calculate driving stresses, energy transfer, and soil resistance .

- CAPWAP®: Refines PDA data via signal matching to estimate static capacity and resistance distribution .

6.2 Soil Improvement Techniques

- Pre-Drilling or Jetting: Reduces driving resistance in dense sands or stiff clays, minimizing remolding .

- Grouting: Enhances soil-pile adhesion post-installation, particularly in corrosive environments .

- Vibroflotation: Densifies loose sands around piles to improve lateral stability .

6.3 Design Adjustments

- Energy Optimization: Using wave equation analyses to select hammers with energy levels balancing drivability and soil preservation .

- Pile Coatings: Epoxy or bitumen coatings reduce skin friction during driving and mitigate corrosion .

7. Conclusions and Future Directions

- Multi-Scale Modeling: Integrating micro-scale soil fabric changes into macro-scale pile-soil interaction models.

- Smart Piles: Embedding fiber-optic sensors for continuous health monitoring post-installation.

- Sustainable Materials: Developing corrosion-resistant alloys and bio-based grouts to enhance durability.