Perforated casing and slotted casing are both used in oil and gas drilling operations, but they serve different functions and have different characteristics. Here’s a summary of the differences:

Perforated Casing

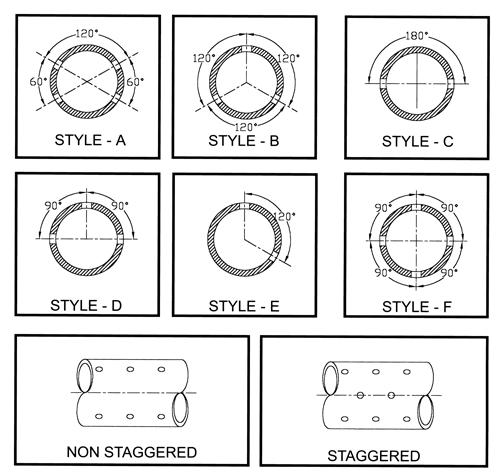

Perforated casing is typically a pipe with holes drilled into it. The size, number, and arrangement of the holes can be customized based on the requirements of the operation.

Key Features:

- It’s used for sand control in coarse-grained formations.

- The perforations allow oil or gas to flow into the casing, where it can be collected and brought to the surface.

- It’s typically used in a well where the formation is stable enough that it won’t collapse into the wellbore.

- The size and placement of the perforations can be precisely controlled, allowing for a high degree of customization based on the specific needs of the well.

- It can also be used to inject fluids into the formation, such as in enhanced oil recovery (EOR) operations or for disposing of wastewater.

Perforated casing is manufacturing with API casing joints with size up to diameter 20″. Every perforated joints is deburred internal and external. Upon request,we can drill standard or customized hole size in any number and any patten.

Technical Specification

| Pipe Size | Holes per feet | Size of hole | Perforated Area per Feet |

| 3/4″ | 78 | 3/16″ | 2.15 |

| 1″ | 54 | 5/16″ | 4.14 |

| 1-1/4″ | 66 | 5/16″ | 5.06 |

| 1-1/2″ | 78 | 5/16″ | 5.98 |

| 2-1/16″ | 78 | 5/16″ | 5.98 |

| 2-3/8″ | 90 | 3/8″ | 9.94 |

| 2-7/8″ | 102 | 3/8″ | 11.26 |

| 3-1/2″ | 126 | 3/8″ | 13.91 |

| 4″ | 138 | 3/8″ | 15.24 |

| 4-1/2″ | 150 | 3/8″ | 16.56 |

| 5″ | 162 | 3/8″ | 17.88 |

| 5-1/2″ | 174 | 3/8″ | 19.21 |

| 6-5/8″ | 186 | 3/8″ | 20.53 |

| 7″ | 222 | 3/8″ | 24.51 |

| 9-5/8″ | 294 | 3/8″ | 32.46 |

Perforated casing is a type of well casing that features a series of small holes drilled into it. The main purpose of these holes is to allow water, gas or oil to flow into the wellbore while blocking out unwanted debris such as sand or shale.

One of the key features of perforated casing is its durability. Because it is made of high-quality steel or other metals, it is highly resistant to corrosion and can withstand harsh wellbore conditions. This makes it an ideal choice for use in oil and gas exploration and production.

Another important characteristic of perforated casing is its flexibility. It can be customized to fit a wide range of wellbore sizes and configurations, ensuring that it provides the best possible fit for each individual well. This adaptability also makes it easy to install and maintain, which can save time and money over the life of a well.

Overall, perforated casing plays a critical role in the success of oil and gas exploration and production. By allowing for the free flow of fluids while keeping out unwanted debris, it helps ensure that wells operate efficiently and effectively for many years to come.

Slotted Casing

Slotted casing is a pipe that has a series of longitudinal slots cut into it. These slots allow fluids to flow into the casing, while at the same time serving to prevent larger particles, like sand, from entering.

Key Features:

- It’s primarily used for sand control in unconsolidated formations.

- The slots are cut in a pattern that provides maximum inflow area while keeping the structural integrity of the pipe.

- The size of the slots is typically larger than the perforations in perforated pipe, meaning that slotted casing can handle a larger volume of fluid.

- However, the larger slot size also means that fine-grained formations may not be effectively controlled, and sand production can be an issue.

- It’s typically easier and cheaper to produce than perforated casing, but it offers less precision in controlling the inflow of fluids.

In summary, the choice between perforated and slotted casing will depend on the specific needs of the well, including the nature of the formation, the volume of fluid expected, and the need for sand control. It’s important to note that both types of casing are just one component of a complex drilling operation, and they need to be considered in the context of the overall drilling plan.