ERW (Electric Resistance Welded) pipe piling is a type of steel pipe that is commonly used in construction and foundation applications, such as in the building of bridges, wharves, and other structures. ERW pipe piling is created by using a process in which a flat steel strip is rolled into a tube shape, and then the edges are heated and welded together using an electric current.

ERW pipe piling has a number of advantages over other types of piling, including:

Cost-effective: ERW pipe piling is generally less expensive than other types of piling, such as seamless pipe piling.

High strength: ERW pipe piling is highly resistant to bending, making it a strong and durable option for foundation applications.

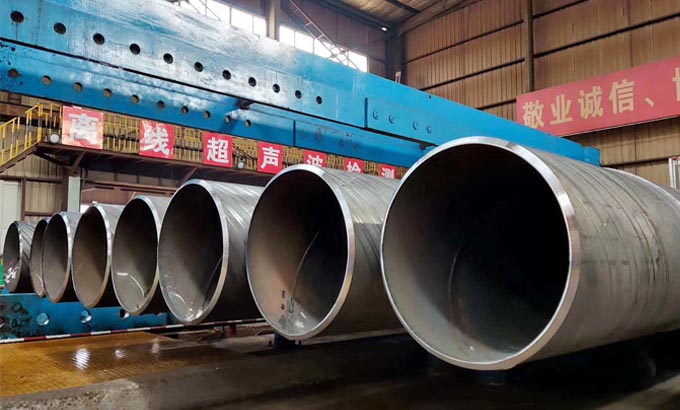

Customizable: ERW pipe piling can be manufactured to meet specific size and length requirements, making it highly customizable and adaptable to different project needs.ERW Pipe Piling is available in a range of sizes and thicknesses, and can be produced in lengths of up to 100 feet or more. It is typically made from carbon steel or alloy steel, and can be coated with a layer of protective material to help prevent corrosion and extend the lifespan of the pipe.

Versatile: ERW pipe piling can be used in a variety of soil conditions, including hard rock, clay, and soft soil.

ERW Pipe Piling is characterized by its high strength and durability, making it suitable for use in heavy-duty applications. It is also relatively inexpensive compared to other types of steel pipe, making it a popular choice for projects with tight budgets. It’s important to consult with a structural engineer or construction professional to determine the best type of piling for your specific project needs.

Why is erw steel pipe used for piling pipe

Depending on the characteristics of the pipe in question, such as its diameter, wall thickness and type of weld used, a steel pipe pile foundation is capable of bearing millions of pounds weight.

Wood piles can be subject to a host of erosion and rotting issues in water, limiting their life span and usability. Driving concrete piles can cause significant vibration and displacement issues, and depending on the environment may not be a viable option.

In contrast,ERW steel pipe pilings can be coated and treated to withstand corrosion, and driving steel piles underwater is easily achieved with the right equipment.ERR Steel pipe can be tailored to fit your precise loading requirements, meaning they can be cheaper to source and install.

They’re relatively lightweight relative to concrete pilings, making them cheaper to transport. And testing and inspection of steel pipe pilings prior to installation is very straightforward.

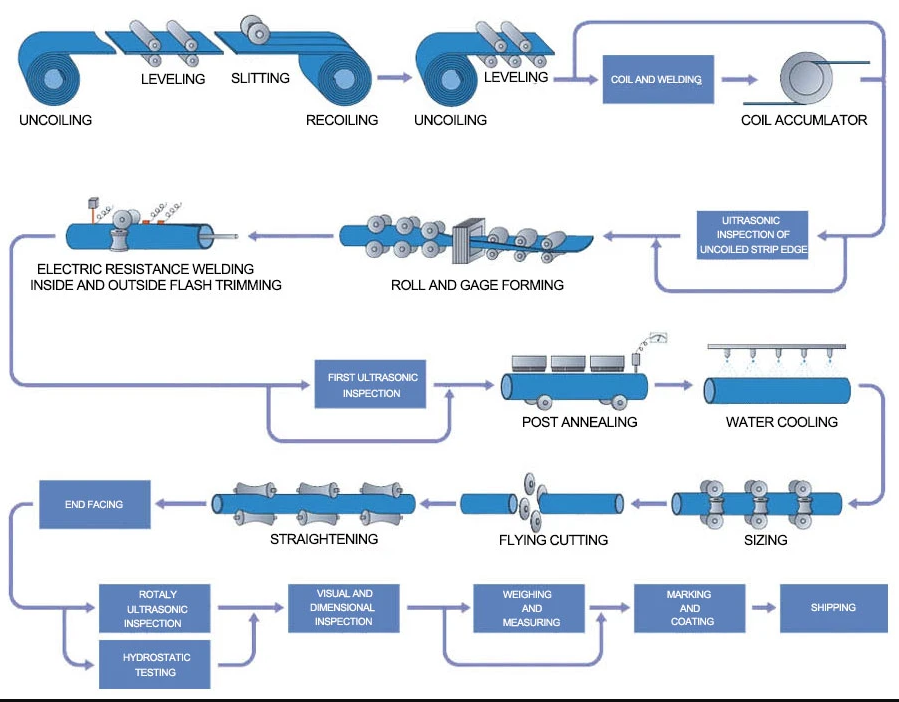

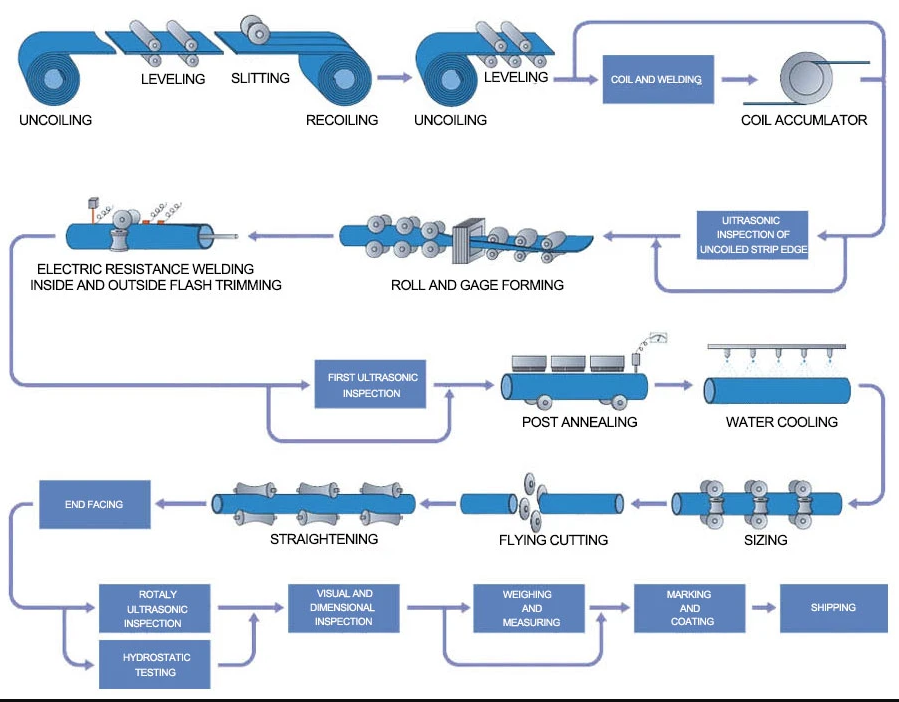

Electric Resistance Welding (ERW) Process

In the Electric Resistance Welding (ERW) process, a flat sheet of steel is cold-formed into a cylindrical shape to manufacture pipe. Then current is applied to either edge of the steel cylinder, and the steel is heated to the point that the edges forcibly form a bond without welding filler material.

This type of welded pipes are majorly used for pipe pile and piling pipe.

API 5L PSL1, PSL2 ERW piling pipe

| Product |

ERW Line Pipe,erw pipe, |

| Process |

Electrical Resistance Weld |

| Standard |

API 5L PSL1, PSL2 |

| Material |

GR.B,X42,X46,X52,X56,X60,X65,X70 |

| O.D |

1/2”–26”(21.3–660mm) |

| W.T |

0.055”–1.602”(1.65–26.97mm) |

| Length |

As per customer’s requirement |

| Surface Treatment |

Bared,Black painted,Corrosion Resistant Coating + Cap |

| Application |

Used for gas,water and oil transportation in oil and gas industry.line pipe, |

ASTM / ASME

| Product Name |

Executive Standard |

Dimension (mm) |

Steel Code / Steel Grade |

| Electric-Resistance-Welded Steel Pipes |

ASTM A135 |

Ø42.2~114.3 x WT2.11~2.63 |

A |

Electric-Resistance-Welded Carbon Steel and

Carbon-Manganese Steel Boiler and Superheater Tubes |

ASTM A178 |

42.2-114.3 x 2.11-2.63 |

A, C, D |

| ERW and Hot-dip Galvanized Steel Pipes |

ASTM A53 |

Ø21.3~273 x WT2.11~12.7 |

A, B |

Pipes for Piling Usage

|

ASTM A252

|

Ø219.1~508 x WT3.6~12.7

|

Gr.2, Gr.3

|

Tubes for General Structural Purpose

|

ASTM A500 |

Ø21.3~273 x WT2.11~12.7 |

Gr.2, Gr.3 |

| Square Pipes for General Structural Purpose |

ASTM A500 |

25 x 25~160 x 160 x WT1.2~8.0 |

Carbon Steel |

DIN

| Product Name |

Executive Standard |

Dimension (mm) |

Steel Code / Steel Grade |

| Threaded Steel Pipes |

DIN 2440 |

Ø21~164 x WT2.65~4.85 |

Carbon Steel |

BS

| Product Name |

Executive Standard |

Dimension (mm) |

Steel Code / Steel Grade |

| Screwed and Socketed Steel Tubes |

BS 1387 |

Ø21.4~113.9 x WT2~3.6 |

Carbon Steel |

EN

| Product Name |

Executive Standard |

Dimension (mm) |

Steel Code / Steel Grade |

| Scaffolding Pipes |

EN 39 |

Ø48.3 x WT3.2~4 |

Carbon Steel |

JIS

| Product Name |

Executive Standard |

Dimension (mm) |

Steel Code / Steel Grade |

| Carbon Steel Tubes for General Structure Purpose |

JIS G3444 |

Ø21.7~216.3 x WT2.0~6.0 |

Carbon Steel |

| Carbon Steel Tubes for Machine Structure Purpose |

JIS G3445 |

Ø15~76 x WT0.7~3.0 |

STKM11A, STKM13A |

| Carbon Steel Pipes for Ordinary Piping |

JIS G3452 |

Ø21.9~216.3 x WT2.8~5.8 |

Carbon Steel |

| Carbon Steel Pipes for Pressure Service |

JIS G3454 |

Ø21.7~216.3 x WT2.8~7.1 |

Carbon Steel |

| Carbon Steel Rigid Steel Conduits |

JIS G8305 |

Ø21~113.4 x WT1.2~3.5 |

G16~G104, C19~C75, E19~E75 |

| Carbon Steel Rectangular Pipes for General Structure |

JIS G3466 |

16 x 16~150 x 150 x WT0.7~6 |

Carbon Steel |

Related Posts

ASTM A252 Pipe Pile

WELDED Steel Pipe Piles (ERW ,LASW, DSAW ,SSAW.) The two most common methods for steel pipe welding are straight seam or spiral seam welding. Welded steel pipes are typically used to transport fluid (water or oil) and natural gas. It is typically less expensive than seamless steel pipe. Both types of welding are applied after the pipe has been rolled, which involves shaping a sheet of steel into the end shape. Straight Seam: Straight seam welded steel pipes are manufactured by adding a welding parallel to the pipe seam. The process is fairly straightforward: Straight seam pipes are formed when a sheet of steel is bent and formed into a pipe shape, then welded longitudinally. Straight seam pipes can be submerged arc welded (SAW) or double-submerged arc welded (DSAW). Spiral Seam: Spiral seam welded pipes are manufactured when hot-rolled strip steel is formed into a pipe through spiral bending and welded along the then spiraled seam of the pipe. This results in the weld length being 30-100% longer than that of a straight seam welded pipe. This method is more commonly used on large diameter pipe. (Note: this method of welding may also be referred to as helical submerged arc Read more

SSAW Pipe Pile | Spiral Weld Steel Pipe Pilings

Spiral weld pipe pile, otherwise known as SSAW Pipe pile, is a type of pipe piling product used in the construction of deep foundations. It is made from steel that has been formed into a spiral shape and welded together. It is used in a variety of applications, including bridge foundations, retaining walls, deep foundations for buildings, dams, and other large structures. Spiral weld pipe pile is a high-strength, low-alloy steel pipe made from a combination of rolled steel plates and helically wound steel strips. It is highly resistant to corrosion and has a high strength-to-weight ratio, making it an ideal choice for deep foundations and other high-load applications. The process of creating spiral weld pipe pile begins with hot-rolling a steel plate into a coil. This coil is then fed into a machine which shapes it into a spiral shape. This spiral is then cut into sections and welded together to form a single pipe pile. After the welding is complete, the pipe pile is then heat treated and tested to ensure it meets the desired specifications. Spiral weld pipe pile is a strong and reliable choice for any deep foundation or other high-load application. It is resistant to Read more

The technical transition of spiral welded steel pipe piles, ASTM A252, EN10219, AWWA C200

Introduction Steel pipe piles have been used for many years as a foundation element in various construction projects. They are commonly used in the construction of bridges, buildings, and other structures that require a strong and stable foundation. The use of steel pipe piles has evolved over the years, with new technologies and techniques being developed to improve their performance and durability. One of the most significant advancements in the use of steel pipe piles is the transition from traditional steel pipe piles to spiral steel welded pipe piles. This paper will explore the technical transition of steel pipe piles to spiral steel welded pipe piles, including the benefits and challenges associated with this transition. PDF Downloads:Tubular Pile, pipe piles, steel piles, tubular pipes Background Steel pipe piles are typically made from steel plates that are rolled into cylindrical shapes and welded together. They are commonly used in deep foundation applications where the soil conditions are poor or where the structure being built is heavy. Steel pipe piles are typically driven into the ground using a pile driver, which forces the pile into the soil until it reaches a predetermined depth. Once the pile is in place, it provides Read more

ASTM A252 Standard Specification for Welded and Seamless Steel Pipe Piles

Standard Specification for Welded and Seamless Steel Pipe Piles1 This standard is issued under the fixed designation A 252; the number immediately following the designation indicates the year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript epsilon (e) indicates an editorial change since the last revision or reapproval. 1. Scope 1.1 This specification covers nominal (average) wall steel pipe piles of cylindrical shape and applies to pipe piles in which the steel cylinder acts as a permanent load-carrying member, or as a shell to form cast-in-place concrete piles. 1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions of the values in inch-pound units to values in SI units. 1.3 The text of this specification contains notes and footnotes that provide explanatory material. Such notes and footnotes, excluding those in tables and figures, do not contain any mandatory requirements. 1.4 The following precautionary caveat pertains only to the test method portion, Section 16 of this specification. This standard does not purport to address all of the safety problems, if any, associated Read more

Steel Pipe Piles / Steel Pipe Sheet Piles

Steel pipe piles and steel pipe sheet piles have found extensive applications in various construction projects, including ports/harbors, urban civil engineering, bridges, and more. These versatile piles are used in the construction of piers, seawalls, breakwaters, earth-retaining walls, cofferdams, and foundations for steel pipe sheet pile foundations. With the increasing size of structures, deeper water depths, and construction work on sites with deep soft ground, the usage of steel pipe piles and steel pipe sheet piles has expanded significantly.

SAWH Steel Piles and Manufacturing Process

In conclusion, SAWH steel piles and SSAW steel pipe piles are essential components in the construction industry, providing strong and reliable foundation systems. Their unique characteristics, manufacturing processes, and advantages make them suitable for a wide range of applications. Whether it's supporting buildings, bridges, or offshore structures, these piles offer the strength, durability, and versatility required for successful construction projects.