How Are Decorative Pipes Different From Industrial Pipes?

Introduction

Pipes are essential components in various applications, serving both functional and aesthetic purposes. While industrial pipes are designed for utility and performance, decorative pipes focus on enhancing visual appeal. This article explores the key differences between decorative and industrial pipes, highlighting their distinct characteristics, materials, applications, and design considerations.

Understanding Decorative Pipes

Purpose and Function

Decorative pipes are primarily used to enhance the aesthetic appeal of a space or structure. They serve as design elements, adding visual interest and complementing the overall decor. While they may also have functional aspects, their primary purpose is decorative.

Materials

Decorative pipes are often made from materials that offer both beauty and durability. Common materials include:

- Stainless Steel: Known for its sleek appearance and corrosion resistance, stainless steel is a popular choice for decorative pipes.

- Copper: Offers a warm, rich color that develops a natural patina over time, adding character to decorative elements.

- Brass: Provides a classic, elegant look with a golden hue, often used in traditional and vintage designs.

- Glass: Used for transparent or translucent decorative pipes, adding a modern and sophisticated touch.

Applications

Decorative pipes are used in a variety of applications, including:

- Interior Design: As part of architectural features, lighting fixtures, or artistic installations.

- Furniture: Incorporated into tables, chairs, and shelving units for a unique design element.

- Exterior Design: Used in landscaping, facades, and outdoor structures to enhance visual appeal.

Design Considerations

When designing decorative pipes, aesthetics take precedence. Key considerations include:

- Finish and Texture: The finish and texture of the material can significantly impact the overall look, with options such as polished, brushed, or matte finishes.

- Color and Coating: Custom colors and coatings can be applied to match specific design themes or preferences.

- Shape and Form: Decorative pipes can be crafted into various shapes and forms, from simple lines to intricate patterns, to achieve the desired visual effect.

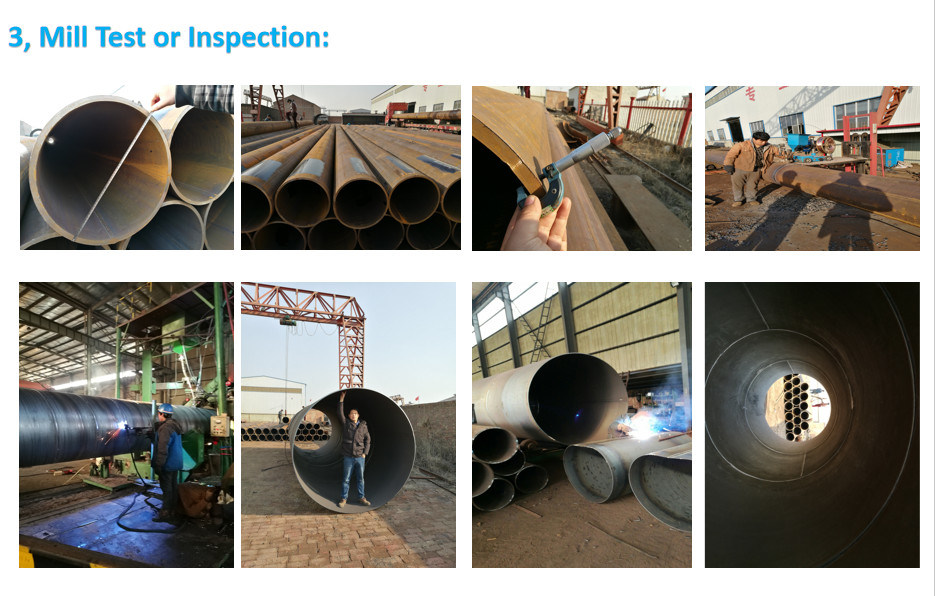

Understanding Industrial Pipes

Purpose and Function

Industrial pipes are designed for utility and performance, serving as conduits for transporting fluids, gases, or solids in various industrial applications. Their primary focus is on functionality, reliability, and safety.

Materials

Industrial pipes are made from materials that offer strength, durability, and resistance to environmental factors. Common materials include:

- Carbon Steel: Known for its strength and affordability, carbon steel is widely used in industrial applications.

- Stainless Steel: Offers excellent corrosion resistance and is suitable for applications involving harsh environments or corrosive substances.

- PVC: A lightweight and cost-effective option for transporting water and other non-corrosive fluids.

- HDPE: High-density polyethylene is used for its flexibility and resistance to chemicals and abrasion.

Applications

Industrial pipes are used in a wide range of applications, including:

- Oil and Gas: For drilling, extraction, and transportation of hydrocarbons.

- Chemical Processing: To transport chemicals and process fluids within industrial facilities.

- Water and Wastewater: For the distribution and treatment of water and wastewater.

- HVAC Systems: To transport air, steam, and other gases in heating, ventilation, and air conditioning systems.

Design Considerations

When designing industrial pipes, functionality and safety are paramount. Key considerations include:

- Pressure and Temperature Ratings: Ensuring the pipe can withstand the operating conditions of the application.

- Corrosion and Chemical Resistance: Selecting materials that can resist corrosion and chemical exposure.

- Size and Capacity: Determining the appropriate size and capacity to meet the flow requirements of the application.

- Compliance and Standards: Adhering to industry standards and regulations to ensure safety and reliability.

Key Differences Between Decorative and Industrial Pipes

Purpose

- Decorative Pipes: Focus on aesthetics and enhancing visual appeal.

- Industrial Pipes: Emphasize functionality, reliability, and safety.

Materials

- Decorative Pipes: Use materials that offer beauty and durability, such as stainless steel, copper, and glass.

- Industrial Pipes: Use materials that provide strength and resistance to environmental factors, such as carbon steel, stainless steel, and PVC.

Applications

- Decorative Pipes: Used in interior and exterior design, furniture, and artistic installations.

- Industrial Pipes: Used in oil and gas, chemical processing, water and wastewater, and HVAC systems.

Design Considerations

- Decorative Pipes: Prioritize aesthetics, including finish, color, and shape.

- Industrial Pipes: Prioritize functionality, safety, and compliance with standards.

Decorative and industrial pipes serve distinct purposes, each playing a vital role in their respective applications. While decorative pipes enhance the visual appeal of spaces and structures, industrial pipes provide essential infrastructure for transporting fluids, gases, and solids. Understanding the differences between these two types of pipes is crucial for selecting the right solution for specific needs, whether it be for aesthetic enhancement or functional performance.

1. What are the main differences between decorative and industrial pipes?

The main differences lie in their purpose, materials, applications, and design considerations. Decorative pipes focus on aesthetics, while industrial pipes prioritize functionality and safety.

2. What materials are commonly used for decorative pipes?

Common materials for decorative pipes include stainless steel, copper, brass, and glass, chosen for their beauty and durability.

3. What materials are commonly used for industrial pipes?

Common materials for industrial pipes include carbon steel, stainless steel, PVC, and HDPE, selected for their strength and resistance to environmental factors.

4. What are some applications of decorative pipes?

Decorative pipes are used in interior and exterior design, furniture, and artistic installations to enhance visual appeal.

5. What are some applications of industrial pipes?

Industrial pipes are used in oil and gas, chemical processing, water and wastewater, and HVAC systems for transporting fluids, gases, and solids.