Applications of Perforated Pipe:

Perforated well screen is a type of filter used in oil and gas wells. It is designed to control the flow of oil and gas from the well, while preventing sand and other debris from entering the well.

perforation in the context of oil wells refers to a hole punched in the casing or liner of an oil well to connect it to the reservoir. Creating a channel between the pay zone and the wellbore to cause oil and gas to flow to the wellbore easily. In cased hole completions, the well will be drilled down past the section of the formation desired for production and will have casing or a liner run in separating the formation from the well bore. The final stage of the completion will involve running in perforating guns, a string of shaped charges, down to the desired depth and firing them to perforate the casing or liner. A typical perforating gun can carry many dozens of explosive charges.

Commonly, perforation guns are run on E-line as it is traditional to use electrical signals from the surface to fire the guns. In more highly deviated wells, coiled tubingmay be used. Newer technologies allow the guns to be run on slickline. Modern slickline technology embeds fiber optic lines that can transmit two-way data on real-time temperature, pressure and seismic responses along the length of the slickline. This information allows very precise operations of various down-hole tools, including perforation guns.

The benefit of this strategy is greater control of the well. Casing the bottom of the hole allows the well to be completed without having to worry about reservoir fluids. It also allows precise selection of where in the formation production will be and to be able to seal off perforations, which are no longer useful or counterproductive, through cementing or straddling.

The disadvantage is that perforating can lead to “skin damage”, where debris from the perforations can hinder productivity of the well. In order to mitigate this, perforating is commonly done underbalanced (lower pressure in the well bore than in the formation) as the lower well bore pressure will cause a surge of fluids into the well at the point of perforating, hopefully carrying the debris with it. Other methods of stimulation such as acidising and proppant fracturing are often required to overcome this damage and bring the well up to its full potential.

Casing and perforating as a method of completion is common place nowadays, though in some unconsolidated formations prone to production of sand (BP Harding as an example), open hole completions using only sandscreens may be the preferred choice.

Oil Well Perforation may be basically classified in two types a) Overbalanced Perforating and b) Underbalanced Perforating. Overbalanced perforating is normally carried out with the help of Perforating Guns or Hollow carriers. In Overbalanced Perforation the weight of the Well-bore Column is more than the Reservoir Pressure, thus it normally ensures that the Well does not start flowing oil or gas immediately after perforation. However, it may have the effect of damaging the formation due to forced entry of well-bore fluid (mud) into the reservoir.

Technical Specifications of Perforated Pipe:

The Slotted Casing Pipe | Slotted Liner Well Screen or Pre-perforated Casing is manufactured with a 44ft 88 spindle drill press. Joints with sizes up to 20” Length range 3 and grades up to 13CR110 are perforated in one handling.

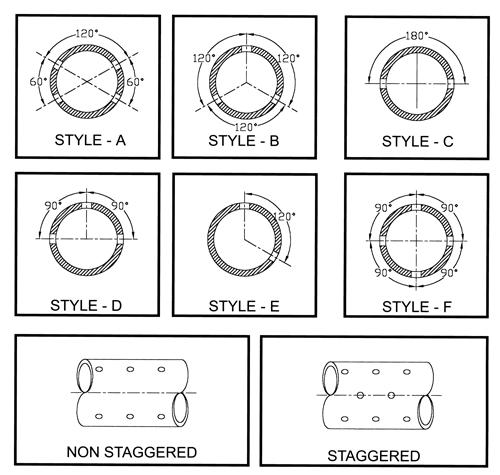

Our standard spiral and staggered perforation patterns use3/8” and 1/2” diameter holes, to create the required open area.

Upon request, custom sizes hold can be drilled in any number and any pattern.

Pipe is deburred internal and external as well as drift tested according to API standards. Every hole is visually inspected and cleaned of burr material.

The size, grade and weight of the base-pipe are according to API casing or tubing specification.

1. Executive standards: API spec 5CT, API spec 5B ASTM A312,ASTM A409,etc

2. Specification range: 2-3/8INCH to 20INCH

3. Carbon Steel Materials grades: J55, K55, N80, L80, C90,T95, P110 and Q125

Stainless steel Material grades:TP304 TP304L TP316 TP316L TP347 TP347H TP321 TP321H TP310 TP310S

TP410 TP410S TP403 S31803/S32205 S32750 S32760|

4. T&C: EUE, NUE, STC, LTC, BTC and Premium connection

5. Pipe/Tube Length: R1,R2,R3(According to customers’ actual demands)

Perforated casing is manufacturing with API casing, joints with size up to diameter 20″and length R3. Every joints perforated is deburred internal and external. Upon request,we can drill standard or customized hole size in any number and nay patter.

Perforated casing is manufacturing with API casing joints with size up to diameter 20″. Every perforated joints is deburred internal and external. Upon request,we can drill standard or customized hole size in any number and any patten.

Technical Specification

| Pipe Size | Holes per feet | Size of hole | Perforated Area per Feet |

| 3/4″ | 78 | 3/16″ | 2.15 |

| 1″ | 54 | 5/16″ | 4.14 |

| 1-1/4″ | 66 | 5/16″ | 5.06 |

| 1-1/2″ | 78 | 5/16″ | 5.98 |

| 2-1/16″ | 78 | 5/16″ | 5.98 |

| 2-3/8″ | 90 | 3/8″ | 9.94 |

| 2-7/8″ | 102 | 3/8″ | 11.26 |

| 3-1/2″ | 126 | 3/8″ | 13.91 |

| 4″ | 138 | 3/8″ | 15.24 |

| 4-1/2″ | 150 | 3/8″ | 16.56 |

| 5″ | 162 | 3/8″ | 17.88 |

| 5-1/2″ | 174 | 3/8″ | 19.21 |

| 6-5/8″ | 186 | 3/8″ | 20.53 |

| 7″ | 222 | 3/8″ | 24.51 |

| 9-5/8″ | 294 | 3/8″ | 32.46 |

| API Casing | ID mm |

Length m |

Slot Length mm |

Slot No. No./m |

Slot width mm |

Slot Tolerance |

Valid Filter Area cm/m |

Max. Strength KN |

||

| Spec mm |

Thickness mm |

Per Weight kg/m |

||||||||

| 60.32 | 5 | 6.84 | 50.3 | 3 | 80 | 200 | 0.3 | ±50 | 48 | 512.54 |

| 73.02 | 5.5 | 9.15 | 62 | 240 | 57.6 | 688.55 | ||||

| 88.9 | 6.5 | 13.22 | 75.9 | 280 | 67.2 | 995.1 | ||||

| 101.6 | 6.5 | 15.22 | 88.6 | 300 | 72 | 1151.2 | ||||

| 114.3 | 7 | 18.47 | 100.3 | 10 | 320 | 76.8 | 1400.4 | |||

| 127 | 7.52 | 22.13 | 112 | 340 | 81.6 | 1673.8 | ||||

| 139.7 | 7.72 | 25.11 | 124.3 | 360 | 86.4 | 1900.2 | ||||

| 9.17 | 29.48 | 121.4 | 360 | 86.4 | 2232.4 | |||||

| 168.3 | 8.94 | 35.09 | 150.4 | 400 | 96 | 2672.95 | ||||

| 177.8 | 8.05 | 33.68 | 161.7 | 440 | 105.6 | 2559.2 | ||||

| 9.19 | 38.19 | 159.4 | 440 | 105.6 | 2940.7 | |||||

Notice: Special sizes which customer required can be provided.

This is a mechanical equipment for manufacturing Perforated Pipe.

Perforated pipe is used for the application of oil reservation layer without much sand or preventing rock bits from dropping off the well bore.

Every joint is put through comprehensive deburring process.

Each hole is visually inspected and cleaned of burr material.

Using multi-spindle milling machines for slotted liners and round hole drilling machines to drill base pipe, we offer a multiple of patterns on 1.900′ – 16” casing. Our slot size capabilities range from 0.012” to .500” and ¼” – ½” ” round holes. All of our machines use a continuous flow of biodegradable coolants to maintain the pipe’s metallurgical integrity.

Perforated pipe Introduction and History

Perforated casing pipe is a type of pipe that is used in many different industries for a variety of different applications. It is a special type of pipe that is made with holes in it that allow for water, oil, gas, or other materials to be pumped through it. It can be used in a variety of different ways, from providing drainage to controlling water flow to providing an efficient means of transporting a variety of materials. This paper will provide an overview of perforated casing pipe, its uses, and its advantages.

The use of perforated casing pipe dates back centuries. Ancient civilizations used it to transport water and other materials, such as grain, through long distances. It was also used in the mining industry to transport ore and other materials. In modern times, the use of perforated casing pipe has become much more widespread. It is used in many different industries and is used in both commercial and residential applications.

Types of Perforated Casing Pipe

Perforated casing pipe comes in a variety of different materials, shapes, and sizes. It can be made from steel, aluminum, plastic, or other materials. The size of the holes in the pipe can also vary, depending on the application. The most common types of perforated casing pipe are round and rectangular, though other shapes can also be made.

Uses

Perforated casing pipe is used in many different industries and applications. In the oil and gas industry, it is used to control water flow, provide drainage, and even for transporting oil and gas. In the agricultural industry, it is used for irrigation, drainage, and crop production. In the construction industry, it is often used for underground water lines and drainage systems. It is also used in the waste management industry for sewage lines and drainage systems.

Advantages

There are many advantages to using perforated casing pipe. It is relatively lightweight and can be easily transported, making it ideal for long-distance applications. It is also easy to install, as it requires only a few simple tools. It is also very durable and can withstand a wide range of temperatures and pressures. As it is made from a variety of materials, it can also be used in a variety of different applications.

Introduction to the working principle of the Perforated Well Screen oil casing:

Perforated well screen is a type of filter used in oil and gas wells. It is designed to control the flow of oil and gas from the well, while preventing sand and other debris from entering the well.

The perforated well screen is made up of several layers of material such as stainless steel, galvanized steel, brass, or other materials. Each layer has small holes or slots in it, allowing oil and gas to pass through while blocking sand and other debris. This type of filter is used to increase the efficiency of the well and to prevent sand and other debris from entering the well and clogging up the production.

Perforated well screens can be used in both surface and subsurface applications. The most common type of perforated well screen is the one used in the production of oil and gas. It is placed between the well casing and the production tubing to control the flow of oil and gas. It is also used in water wells to prevent sand and other debris from entering the well.

Perforated well screens are usually made up of a series of concentric circles, or slots, which are punched into the material. These slots are designed to allow oil and gas to pass through while blocking sand and other debris. The size of the slots will depend on the application. For oil and gas wells, the holes are usually about 0.25 to 0.5 inch in diameter.

The perforated well screen is usually placed in the well casing and then attached to the production tubing with a series of threaded connectors. It is important to ensure that the connectors are securely fastened and that the screen is firmly attached to the well casing.

Perforated well screens come in a variety of materials, including stainless steel and galvanized steel. Stainless steel is the most common material used, as it is highly resistant to corrosion and can withstand the harsh conditions in a well. Galvanized steel is also a popular choice, as it is less expensive and more durable than stainless steel.

Perforated well screens can be installed by a professional or by the well owner. Installing a perforated well screen requires the use of specialized tools, such as a drill, wrenches, and other tools. The installation process can be complicated and requires a certain degree of skill and experience.

Once the perforated well screen is installed, it is important to test it regularly to ensure that it is working properly. This can be done by monitoring the flow of oil and gas through the well. If the flow is not consistent, or if the screen is not working properly, it may need to be replaced.

Perforated well screens can be an effective way to control the flow of oil and gas from a well, while preventing sand and other debris from entering the well. They are easy to install and maintain, and they are available in a variety of materials and sizes.