Steel pipe piles are an essential component in the construction of deep foundations, bridges, offshore platforms, and various other structures. Steel is classified into various grades and types based on its chemical composition, mechanical properties, and manufacturing methods. In this article, we will discuss the different types of steel materials used for steel pipe piles, including their properties, advantages, and applications.

1. Carbon Steel

Carbon steel is the most common type of steel used for pipe piles. It is divided into three main categories based on the carbon content: mild or low-carbon steel, medium-carbon steel, and high-carbon steel.

1.1 Mild or Low-Carbon Steel

Mild steel has a carbon content of up to 0.30%. It is known for its excellent weldability, ductility, and relatively low cost. Some common grades used for pipe piles include:

- ASTM A36: A popular structural steel with a minimum yield strength of 36,000 psi.

- ASTM A283: A low-to-intermediate tensile strength carbon steel suitable for general structural purposes.

1.2 Medium-Carbon Steel

Medium-carbon steel contains between 0.30% and 0.60% carbon and is stronger and harder than low-carbon steel. Some common grades used for pipe piles include:

- ASTM A572: A high-strength, low-alloy steel with improved weldability and formability.

- ASTM A529: A medium-carbon, manganese steel with good strength, ductility, and weldability.

1.3 High-Carbon Steel

High-carbon steel contains between 0.60% and 1.00% carbon, making it harder and stronger than medium-carbon steel. It is less ductile and more challenging to weld, so it is less commonly used for pipe piles.

CARBON STEEL API standard.

| Steel grade according to EN10219-1 | Minimum yield strength Reh (T≤16mm) N/mm2 | Minimum yield strength Reh (16≤T≤40mm) N/mm2 | Minimum ultimate tensile strength Rm (3≤T≤40mm) N/mm2 | Minimum elongation (T≤40mm) % |

| S235JRH | 235 | 225 | 340-47- | 22 |

| S275JOH/J2H | 275 | 265 | 410-560 | 20 |

| S355JOH/JEH | 355 | 345 | 490-630 | 20 |

| S420MH | 420 | 400 | 500-660 | 19 |

| S460MH | 460 | 440 | 530-720 | 17 |

| Steel grade according to API5L,PSL1 | Minimum yield strength Reh N/mm2 | Minimum ultimate tensile strength Rm N/mm2 | Minimum elongation % | |

| B | 245 | 415 | 23 | |

| X42 | 290 | 415 | 23 | |

| X46 | 320 | 435 | 22 | |

| X52 | 360 | 460 | 21 | |

| X56 | 390 | 490 | 19 | |

| X60 | 415 | 520 | 18 | |

| X65 | 450 | 535 | 19 | |

| X70 | 485 | 570 | 17 | |

| 1)PSL:Product Specification Level | ||||

| 2)T:Thickness | ||||

| 3)Depends on tensile test piece cross sectional area | ||||

European steel pipes

| Steel grade according to EN10219-1 | C Max% | Mn Max % | P Max % | S Max % | Si Max % | N Max % | CEV Max % |

| S235JRH | 0.17 | 1.40 | 0.045 | 0.045 | – | 0.009 | 0.35 |

| S275JOH/J2H | 0.20 | 1.50 | 0.040 | 0.040 | – | 0.009 | 0.40 |

| S355JOH/JEH | 0.22 | 1.60 | 0.040 | 0.040 | 0.55 | 0.009 | 0.45 |

| S420MH | 0.16 | 1.70 | 0.035 | 0.030 | 0.50 | 0.020 | 0.43 |

| S460MH | 0.16 | 1.70 | 0.035 | 0.030 | 0.60 | 0.025 | – |

| Steel grade according to API5L,PSL1 | C Max% | Mn Max % | P Max % | S Max % | Ti+V+Nb Max % | ||

| B | 0.26 | 1.20 | 0.030 | 0.030 | 0.15 | ||

| X42 | 0.26 | 1.30 | 0.030 | 0.030 | 0.15 | ||

| X46 | 0.26 | 1.40 | 0.030 | 0.030 | 0.15 | ||

| X52 | 0.26 | 1.40 | 0.030 | 0.030 | 0.15 | ||

| X56 | 0.26 | 1.40 | 0.030 | 0.030 | 0.15 | ||

| X60 | 0.26 | 1.40 | 0.030 | 0.030 | 0.15 | ||

| X65 | 0.26 | 1.45 | 0.030 | 0.030 | 0.15 | ||

| X70 | 0.26 | 1.65 | 0.030 | 0.030 | 0.15 |

1) According to API 5L: For each reduction of 0.01% below the specified maximum carbon content, an increase of 0.05% above the specified maximum manganese content is permissible, up to a maximum of 1.50% for grade X42 to X52, 1.65% for X56 to X65 and 2.00% for X70

2)Unless otherwise agreed, the sum of the niobium and vanadium contents shall be ≤ 0.06 %.

3) Unless otherwise agreed

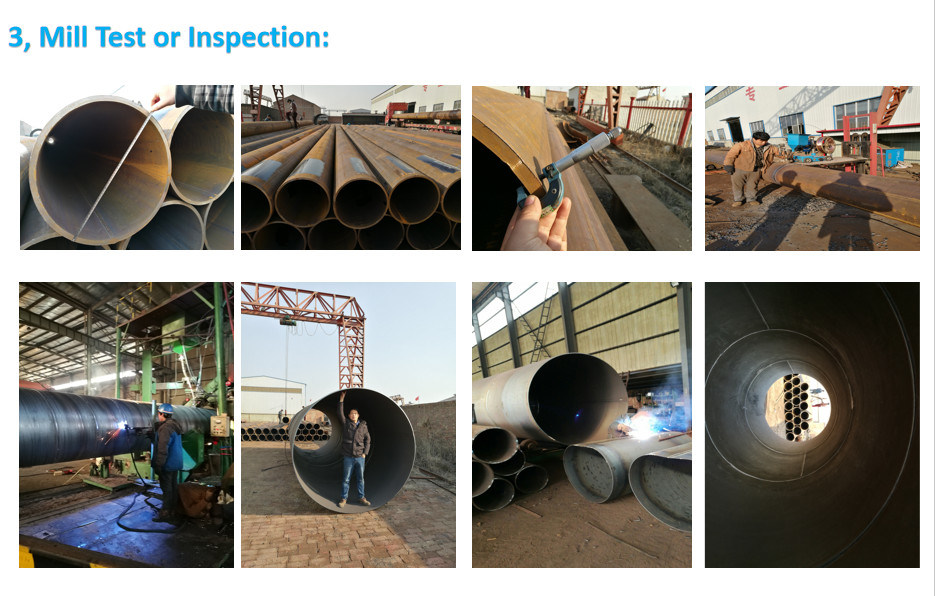

Dimensional tolerances for pipe piles

| Standard | Outside diameter D | Wall Thickness T | Straightness | Out-of-roundness | Mass | Maximum weld bead height | |||

| EN10219-2 | +/-1% Max +/-10.0mm | +/-1% Max +/-2.0mm | 0.20% of total length | +/-2% | +/-6% | T≤14.2mm:3.5mm T >14.2mm:4.8mm | |||

| API5L ISO3183 | ≤1422mm | +/-0.5% ≤4.0mm | <15.0mm:+/-10% ≥ 15.0 mm:+/-1.5mm | 0.20% of total length | D/t≤75 D<1422mm | +/-1.5% ≤15.0mm | +10% -3.5% | T≤13.0mm:3.5mm T >13.0mm:4.8mm | |

| >1422mm | As agreed | Else | As agreed | ||||||

2. Alloy Steel

Alloy steel is a type of steel where other elements, such as chromium, nickel, and molybdenum, are added to improve its mechanical properties and corrosion resistance. Some common alloy steel grades used for pipe piles include:

- ASTM A588: A high-strength, low-alloy steel with excellent atmospheric corrosion resistance.

- ASTM A690: A high-strength, low-alloy steel with improved corrosion resistance in marine environments.

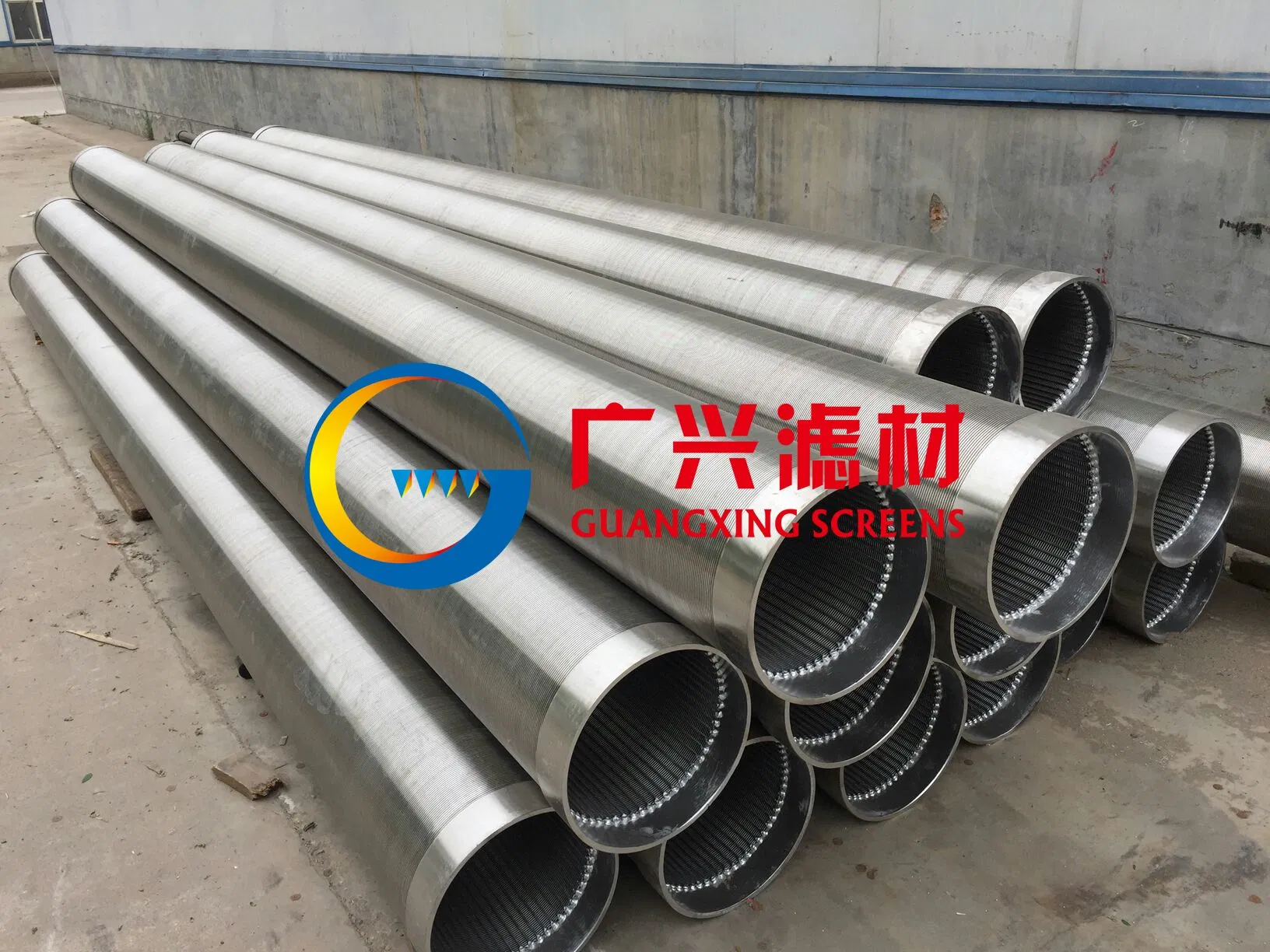

3. Stainless Steel

Stainless steel is a type of steel containing at least 10.5% chromium, which gives it exceptional corrosion resistance. It is often used in environments where corrosion is a concern, such as marine or coastal applications. Some common grades of stainless steel used for pipe piles include:

- 304/304L: A popular austenitic stainless steel with good corrosion resistance and mechanical properties.

- 316/316L: Another austenitic stainless steel with higher corrosion resistance than 304, particularly in chloride environments.

4. High-Strength Low-Alloy (HSLA) Steel

HSLA steel is a type of alloy steel with a small amount of alloying elements, which significantly increases its strength compared to carbon steel. It is designed to have better mechanical properties, corrosion resistance, and weldability. Some common HSLA steel grades used for pipe piles include:

- ASTM A572: As mentioned earlier, this grade offers high strength, improved weldability, and formability.

- ASTM A709: A high-strength, low-alloy steel used primarily for bridge construction.

5. Weathering Steel

Weathering steel, also known as Corten steel, is a type of steel that develops a protective oxide layer when exposed to atmospheric conditions. This layer protects the steel from further corrosion, eliminating the need for paint or other protective coatings. Some common weathering steel grades used for pipe piles include:

- ASTM A588: As mentioned earlier, this grade offers excellent atmospheric corrosion resistance and high strength.

- ASTM A847: A high-strength, low-alloy steel with improved corrosion resistance in comparison to carbon steel.

In conclusion, there are various types of steel materials available for steel pipe piles, each with its unique properties and applications. The selection of the appropriate steel material depends on factors such as the required strength, corrosion resistance, weldability, and cost. By understanding the properties and applications of these steel materials, engineers and contractors can make informed decisions to ensure the success of their projects.