pipe piles

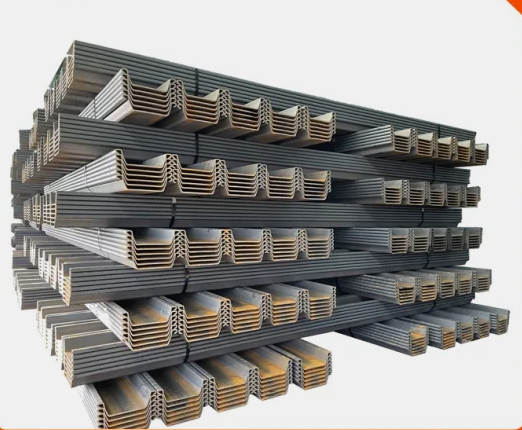

Carbon Steel Sheet Pile Retaining Walls

Abtersteel's Carbon Steel Sheet Pile Retaining Walls, encompassing Cold Formed and Hot Rolled Sheet Piles, represent the pinnacle of construction technology. With detailed specifications, versatile applications, and a commitment to quality, these products are designed to meet the evolving needs of modern infrastructure. Whether you're building a temporary cofferdam or a permanent seawall, our sheet piles deliver the strength, durability, and efficiency required to bring your vision to life. Contact Abtersteel today to explore how our solutions can elevate your next project.

Hot-Rolled Steel Sheet Pile VS Cold-Formed Steel Sheet Pile

The choice between HRSSP and CFSSP depends on project requirements. HRSSP offers superior strength, watertightness, and durability, while CFSSP provides flexibility, availability, and cost savings. By understanding their parameters, dimensions, and scientific underpinnings, engineers can optimize designs for performance and economy.

EN 10248-1 Steel Sheet Piles for Levee Strengthening

EN 10248-1 steel sheet piles are indispensable for levee strengthening projects, offering durability, cost-effectiveness, and sustainability. As flood risks grow, their importance in civil engineering will only increase. Engineers and decision-makers should prioritize these solutions for reliable flood control.

ASTM A252 GR.1 GR.2 GR.3 Welded Steel Pipe Pile

ASTM A252 GR.1-GR.3 welded steel pipe piles are critical components in modern construction and foundation engineering. Known for their exceptional strength, weldability, and versatility, they play a pivotal role in ensuring stability for buildings, bridges, marine structures, and offshore platforms.

By selecting the appropriate grade, manufacturing process, and corrosion protection, engineers and contractors can achieve reliable, long-lasting solutions for their structural needs. ASTM A252 remains a cornerstone specification for projects demanding high performance under challenging conditions.

Profile Steel Piles – H-Beam | U-Shaped | Z-Shaped | Pipe Steel Pile

Profile steel piles are a cornerstone of modern infrastructure, providing unmatched strength, durability, and versatility. Their applications range from deep foundations to marine construction, making them indispensable in the civil engineering industry. By selecting the appropriate pile type, coating, and installation method, engineers can achieve long-term structural stability while minimizing costs and environmental impact.

Steel Pipe Piling Manufacturing Process

The manufacturing process of steel pipe piling is a highly specialized and controlled procedure designed to produce durable, high-quality piles for demanding applications. From preparation and rolling to welding, assembly, and coating, each stage is optimized to meet stringent industry standards. Non-destructive testing and comprehensive documentation ensure the reliability and traceability of the final product.

Tubular Combined Walls

Pipe piles are very simple and easy to understand deep foundation system. A pre-manufactured steel pipe section is driven into the ground until refusal is reached. Installing Pipe Piles can be achieved with three different types of equipment types, vibratory, drilled and pneumatic hammer (Pile design, Pile depth and Site Conditions are major factor) The pile designs will vary depending on the soil conditions and load requirements.

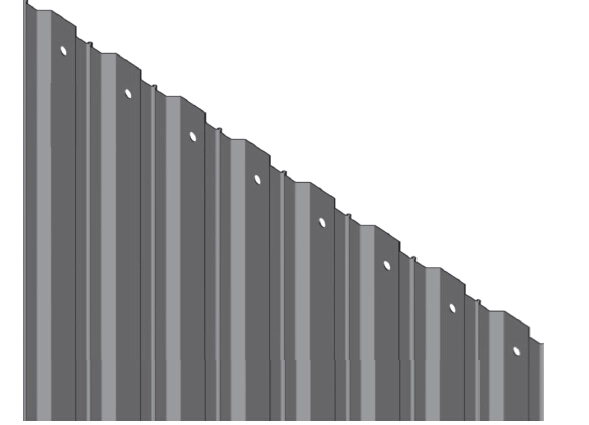

Trench Sheet Piles

Steel trench sheets can be supplied in a variety of profiles and length and steel grades. Overlapping trench sheets are without interlocks. While interlocking trench sheeting is like other kind of sheet piles, connected with interlocks. Since trench sections are also produced from cold rolling technology, so any sections can be produced, like RC sections etc.

Overlap Sheet Pile

The Overlap Sheet Pile, is designed to be used as a means of temporary closing off an open side of a trench shield. Overlap design allows for easy installation of the sheets.

Heavy-Duty Anti-Corrosion Steel Pipe Pile

Pipe piling has a wide range of applications across different sectors due to its versatility and strength. Here are some of the primary uses:

Foundational Support

For buildings, bridges, and other structures requiring deep foundations, pipe piles are driven deep into the ground to reach load-bearing strata. This ensures stability and prevents settlement.

High-Rise Buildings: In urban areas with soft soils, pipe piles provide necessary support for skyscrapers and other tall structures.

Industrial Facilities: Factories and warehouses with heavy equipment and machinery often require robust foundations provided by pipe piles.

Omega Type Sheet Piles

Ω Sheet Pile

Advantages:

1. An innovative section to ease sheet piling installation that is adjacent to existing building.

2. An innovative manufacturing process allows changing of profile width that provides a wide range of omega sections.

3. High-width reduces the number of interlock per meter run of wall and directly improves water tightness control of wall.

Heavy-Duty “Z” Sheet Piling: A Strong Foundation for Construction Projects

By considering the specifications of heavy-duty "Z" sheet piling, you can make informed decisions and ensure the success and stability of your construction project.

Open-End vs. Closed-End Pipe Piles: Understanding the Differences

By understanding the differences between open-end and closed-end pipe piles, you can make an informed decision that will contribute to the stability and longevity of your construction project. Whether you opt for the easy penetration and cost-effectiveness of open-end pipe piles or the minimized soil disturbance and suitability for cohesive soils of closed-end pipe piles, selecting the right pile type is crucial for a successful foundation.

Steel Pipe for Friction Pile

Steel Pipe for Friction Pile: An Overview Steel pipe piles are commonly used in construction projects, particularly in foundation systems such as friction piles. Friction piles rely on the frictional resistance between the pile and the surrounding soil to transfer the load to the ground. In this article, we will explore the use of steel...

EN10219 Welded Steel Pipe Piles

EN10219 spiral welded steel pipe piles offer numerous advantages in terms of strength, durability, cost-effectiveness, versatility, and environmental sustainability. Their applications in foundation construction, marine structures, retaining walls, infrastructure projects, and the oil and gas industry highlight their versatility and reliability. When it comes to choosing a foundation solution that provides stability and long-term performance, EN10219 spiral welded steel pipe piles are an excellent choice. Their unique features and benefits make them a preferred option for construction professionals seeking reliable and efficient foundation solutions.

SAWH Steel Piles and Manufacturing Process

In conclusion, SAWH steel piles and SSAW steel pipe piles are essential components in the construction industry, providing strong and reliable foundation systems. Their unique characteristics, manufacturing processes, and advantages make them suitable for a wide range of applications. Whether it's supporting buildings, bridges, or offshore structures, these piles offer the strength, durability, and versatility required for successful construction projects.

Steel Pipe Piles / Steel Pipe Sheet Piles

Steel pipe piles and steel pipe sheet piles have found extensive applications in various construction projects, including ports/harbors, urban civil engineering, bridges, and more. These versatile piles are used in the construction of piers, seawalls, breakwaters, earth-retaining walls, cofferdams, and foundations for steel pipe sheet pile foundations. With the increasing size of structures, deeper water depths, and construction work on sites with deep soft ground, the usage of steel pipe piles and steel pipe sheet piles has expanded significantly.

ASTM A252 Standard Specification for Welded and Seamless Steel Pipe Piles

Standard Specification for Welded and Seamless Steel Pipe Piles1 This standard is issued under the fixed designation A 252; the number immediately following the designation indicates the year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript epsilon...

The technical transition of spiral welded steel pipe piles, ASTM A252, EN10219, AWWA C200

Introduction Steel pipe piles have been used for many years as a foundation element in various construction projects. They are commonly used in the construction of bridges, buildings, and other structures that require a strong and stable foundation. The use of steel pipe piles has evolved over the years, with new technologies and techniques...

SSAW Pipe Pile | Spiral Weld Steel Pipe Pilings

Spiral weld pipe pile, otherwise known as SSAW Pipe pile, is a type of pipe piling product used in the construction of deep foundations. It is made from steel that has been formed into a spiral shape and welded together. It is used in a variety of applications, including bridge foundations, retaining walls, deep foundations...

ASTM A252 Pipe Pile

WELDED Steel Pipe Piles (ERW ,LASW, DSAW ,SSAW.) The two most common methods for steel pipe welding are straight seam or spiral seam welding. Welded steel pipes are typically used to transport fluid (water or oil) and natural gas. It is typically less expensive than seamless steel pipe. Both types of welding are applied after...

ERW piling pipe | ERW Steel Pipe Pile | Welded ERW for Structure

ERW (Electric Resistance Welded) pipe piling is a type of steel pipe that is commonly used in construction and foundation applications, such as in the building of bridges, wharves, and other structures. ERW pipe piling is created by using a process in which a flat steel strip is rolled into a tube shape, and then...

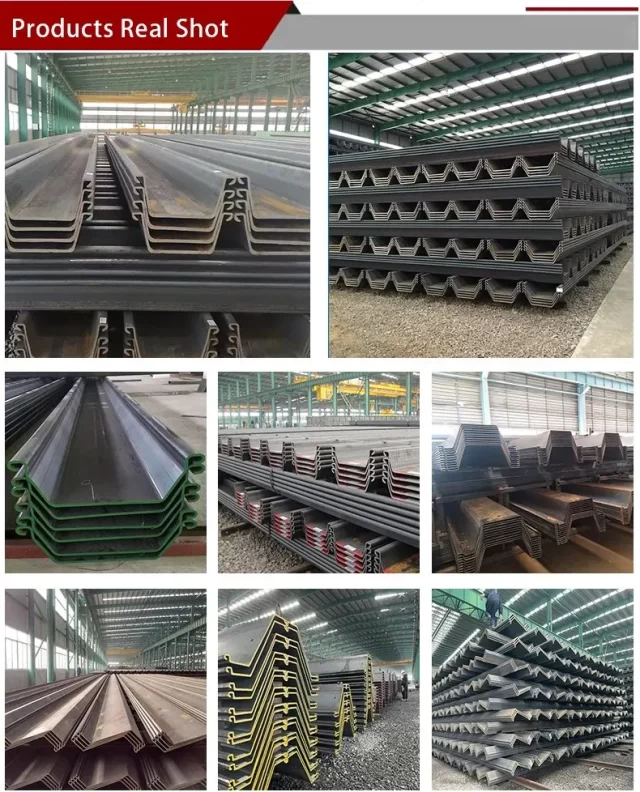

Steel sheet piles

Z-Shaped Steel Sheet Piles for Construction

Outline for “Z-Shaped Steel Sheet Piles for Construction” Main Topics Subtopics Introduction to Z-Shaped Steel Sheet Piles – What are Z-shaped steel sheet piles? – Importance in construction Features of Z-Shaped Steel Sheet Piles – Design and geometry – Durability and material composition Applications of Z-Shaped Steel Sheet Piles – Retaining walls – Cofferdams –...

ERW Steel Pipe Piles

ERW steel pipe piles are a versatile and cost-effective solution for various industrial applications. Their high corrosion resistance, toughness, and strength make them ideal for water well drilling, construction projects, and engineering facilities. The electric resistance welding process ensures consistent quality and structural integrity, making ERW pipe piles a reliable choice for many projects.

JIS 5528 Steel Sheet Piles : SY295, SY390, SYW295 steel grades

JIS 5528 - Japanese Industrial Standard for Steel Sheet Piles

JIS 5528 is a Japanese Industrial Standard that outlines the technical requirements for steel sheet piles. Similar to En 10249, JIS 5528 covers various types of sheet pile profiles, including U-type, Z-type, and straight web sections. It specifies the dimensions, tolerances, steel grades, and mechanical properties of the sheet piles.

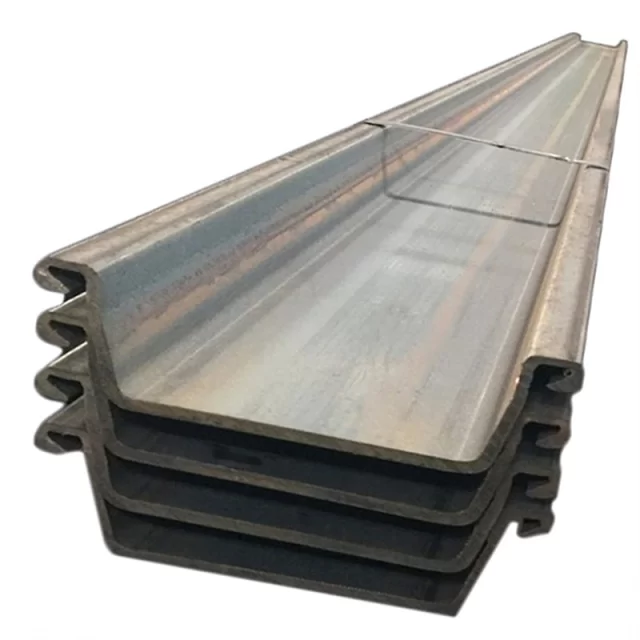

U-Shaped Steel Sheet Piles

The steel sheet pile is very wide, in the permanent structure of the building, can be used for wharf, unloading yard, embankment revetment, wall, retaining wall, breakwater, diversion embankment, dock, gate, etc.; In temporary structures, can be used to seal the mountain, temporary shore expansion, cut-off, bridge cofferdam, large pipeline laying temporary ditch excavation retaining, water, sand, and so on; In flood fighting, it can be used for flood control, collapse prevention, sand and so on.

Z-Shaped Steel Sheet Piles

Z-shaped steel sheet piles are produced in a zigzag form and are typically driven in crimped or welded doubles. These piles offer a unique set of benefits, particularly for port construction and deep foundations where their higher modulus and use as intermediate piles in tubular & HZ combination walls is advantageous.

Advantages of Z-Shaped Steel Sheet Piles

Flexible Design and High Section Modulus: Z-shaped steel sheet piles offer a high section modulus and mass ratio, allowing for flexible design according to the project's needs.

Higher Moment of Inertia: The higher moment of inertia increases the stiffness of the sheet pile wall and reduces displacement deformation.

Large Width: The large width of these piles saves time during lifting and piling.

Corrosion Resistance: Parts of the sheet pile that are prone to serious corrosion undergo thickening treatment, enhancing corrosion resistance.

Lighter Weight: The weight per square meter of a Z sheet pile is always less than that of a U sheet pile for a similar section modulus, making it a more efficient choice.

Use as Infill Pile: Z-shaped sheet piles can be used as infill piles together with steel pipes and H-beams. They are typically used to achieve a very high modulus.

U-type Steel Sheet Piles

U-type Steel Sheet Pile

U-type profile interlocked on both sides to form a continuous wall with centerline in the middle of a double U section wall.

What are the advantages of sheet piling?

Like other steel piling shapes, sheet piling is driven into the ground to provide stability and support for a range of construction applications. As its name suggests, these are steel sheets that form a support wall, rather than the round or H-shaped cross sections of other piling shapes. Sheet piling has both temporary and permanent uses, usually as retaining walls for excavation, underground structures, or seawalls.

STEEL SHEET PILING Types and Applications

Hot Rolled Sheet Piles are formed by profiling the steel with high temperatures as the rolling process occurs. Typically, hot rolled sheet piles are produced to BS EN 10248 Part 1 & 2. Greater thicknesses are achievable than cold rolled sheet piles. The interlocking clutch tends to be tighter as well.

Z-type sheet piles

We sell and rent three different hot-rolled, "Z" type sheet piling products, flat piling and combination systems to ensure that we can match the needs of your application.The Z shape of each section lends to its structural strength which is determined not only by the size, but also by the thickness of the steel. Of course, the soil conditions in which the section is driven will also affect the performance of the foundation or wall.

What types of Steel Sheet Piles ? Z-type Steel Sheet Piles advantages

There are three forms or shapes of steel sheet piles: Z-shaped, U-shaped and Straight Web Sections.Z-shaped sheet piles are considered to be the most efficient of the shapes. They are used for intermediate and deep wall construction and commonly for tied back and cantilever retaining walls. U-shaped profiles are used for similar applications, but their resistance to bending is lower than Z-shaped piles.

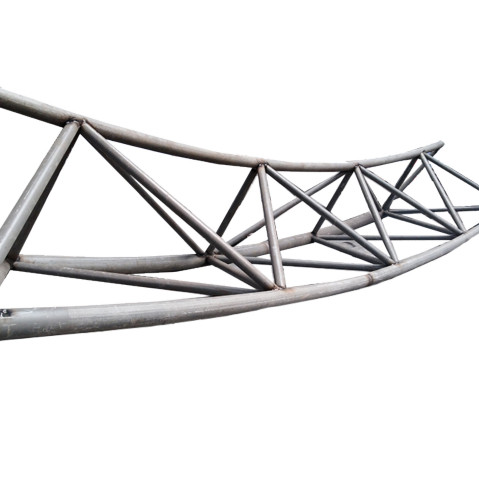

steel trusses for construction

Steel Pipe Truss – Metal Structure Buildings

Comprehensive Guide to Steel Pipe Trusses Introduction In modern construction, steel pipe trusses have become a popular choice for supporting large-span structures due to their strength, versatility, and aesthetic appeal. These trusses are widely used in various industries, including industrial buildings, warehouses, stadiums, and bridges, where the ability to span large distances without internal...

Large Span Roof Structure Space Frame

By understanding the key features, materials, and design considerations involved in the construction of space frames, you can make informed decisions when selecting the right structure for your project. Additionally, the advantages of Abter Steel space frames, including their lightweight design, high strength, and cost-effectiveness, make them an ideal choice for large-span roof applications.

Research of Large-Span Steel Pipe Truss Structures

Large-span steel pipe truss structures represent the pinnacle of engineering and architectural collaboration, enabling the creation of expansive, open spaces that inspire and serve diverse functions. Through advanced design, analysis, and construction techniques, these structures achieve remarkable strength, flexibility, and aesthetic appeal. As technology and materials continue to evolve, the capabilities and applications of large-span trusses will expand, offering new possibilities in the built environment. If you have any more questions or need further details, feel free to ask!

Steel Pipe Truss System: Customized Engineering and Professional Production

Customized engineering and professional production are essential for creating steel pipe truss systems that meet the specific needs of modern construction projects. By leveraging advanced design tools, skilled craftsmanship, and rigorous quality control, these systems offer unparalleled strength, flexibility, and aesthetic appeal. As technology and materials continue to evolve, the capabilities and applications of customized truss systems will expand, offering new possibilities in architecture and engineering. If you have any more questions or need further details, feel free to ask!

Custom Metal Welding Fabrication of Pipe Truss Steel Structures

Custom metal welding fabrication of pipe truss steel structures is a complex process that requires expertise, precision, and careful planning. By understanding the materials, techniques, and challenges involved, fabricators can create strong, reliable structures that meet the demands of modern construction. As technology and materials continue to evolve, the capabilities and applications of these structures will expand, offering new possibilities in the field of engineering and architecture. If you have any more questions or need further details, feel free to ask!

Cold-Bent and Hot-Bent Carbon Steel Pipe Truss

Cold-bent and hot-bent carbon steel pipe trusses each offer unique advantages and are suited to different applications. Understanding their characteristics and limitations is essential for selecting the right truss type for a given project. As technology and materials continue to evolve, the capabilities and applications of these trusses will expand, offering new possibilities in construction and engineering. If you have any more questions or need further details, feel free to ask!

The Lateral Stability of Trusses: Ensuring Structural Integrity Introduction

Explore the principles of lateral stability in trusses, covering factors affecting stability, methods to enhance it, and the critical role of lateral bracing to ensure structural integrity and safety.

Pipe Bending | bend pipe for construction

The seasoned professionals at Abter Steel set the standard for Pipe bending with the following three processes:

Space pipe trusses for long-span steel structures

if you're planning a construction project that requires a long-span steel structure, consider the benefits of space pipe trusses. Their innovative design and numerous advantages make them a compelling choice for architects, engineers, and project owners alike. Embrace the possibilities of space pipe trusses and unlock a world of architectural and structural possibilities.

Carbon Steel Roofing Steel Pipe Truss

Carbon steel roofing steel pipe truss offers a strong, durable, and versatile solution for roofing systems. Its combination of carbon steel and the pipe truss design provides exceptional structural integrity, design flexibility, and longevity. With applications in commercial, residential, sports, agricultural, and industrial buildings, carbon steel roofing steel pipe truss proves to be a reliable choice for various projects. Its fire resistance, energy efficiency, and sustainability further enhance its appeal. Consider carbon steel roofing steel pipe truss for your next roofing project and enjoy the benefits of a robust and visually appealing roofing system.

Roofing Steel Pipe Truss Structure

The carbon steel roofing steel pipe truss is a reliable and robust solution for roofing systems. Its combination of carbon steel and the pipe truss design provides exceptional strength, durability, and load-bearing capacity. With applications in various industries and buildings, including airports, stadiums, and leisure facilities, the steel truss offers a versatile and efficient solution. Consider utilizing carbon steel roofing steel pipe truss in your next construction project to ensure a strong and reliable roofing system.

Pipe Truss for Steel Structures Remarkable Mechanics and Features

Explore the future potential of pipe truss in steel structures and ongoing advancements in the industry.

Discuss the continuous research and development efforts to optimize the performance and sustainability of pipe truss systems.

Steel Pipe Trusses Structure: Innovation in Structural Design

Large Span Prefabricated Building Metal Frame Shed Warehouse Steel Structure ,Steel material

Structural steel Q235B, Q345B, or others as buyers' requests.

Purlin

C or Z purlin: Size from C120~C320, Z100~Z20

Bracing

X-type or other type bracing made from angle, round pipe

What type of steel is used for roof truss?

These Aluminum Bolt Square Truss are always used as background frame and for light lighting .Connect each truss with pin part and easy to set up .Length or thickness can be customized according to customer’s requirement. Truss Material Aluminum alloy 6082-T6 Light duty truss 200*200mm 220*220mm Medium duty truss 290*290mm 300*300mm 350*350mm 400*400mm 450*450mm 400*600mm...

Pipe Truss Steel Structure

Pipe trusses, also known as tubular trusses, are structural frameworks composed of interconnected pipes. These trusses form a triangular or quadrilateral shape to provide stability and distribute loads evenly, allowing for the construction of large and complex structures. The pipes used in pipe trusses are typically made of steel or aluminum due to their high strength-to-weight ratio and durability.

Large Span Steel Pipe Trusses Structure

Roofing Systems: Pipe trusses are commonly used as roofing systems in commercial, industrial, and even residential buildings. The triangular or quadrilateral shape of the trusses provides excellent load-bearing capacity, allowing for large spans without the need for intermediate supports. This design feature creates expansive interior spaces and facilitates efficient use of the building.

Steel Pipe Roof Trusses for construction

Advantages of Tubular Truss Steel Structure: Compared with space truss structure, pipe truss structure eliminates vertical bar and space truss bottom chord node, which can meet the requirements of various architectural forms, especially arch and arbitrary curved shape construction is more advantageous than space truss structure. Its stability is different and material consumption is saved....

pipe trusses for construction

In the realm of construction, finding the right structural solution is crucial for ensuring the safety, strength, and efficiency of a building. One such versatile and reliable option gaining popularity in recent years is the use of pipe trusses. These trusses, constructed from interconnected pipes, offer numerous advantages in terms of strength, flexibility, and cost-effectiveness. In this article, we will explore the concept of pipe trusses, their applications, and the benefits they bring to construction projects.

Water well screen

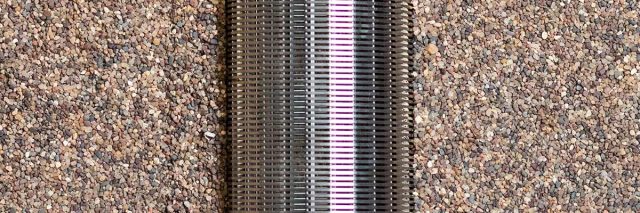

Water Well Screens – WELL PACK SAND & GRAVEL

Water Well Screens: Comprehensive Guide to Abter’s Premium Products Water well screens are crucial components in various water and oil well applications, ensuring efficient filtration and protection of the well casing. Abter, a leading manufacturer, offers a wide range of water well screens tailored to meet different needs and specifications. This article delves into...

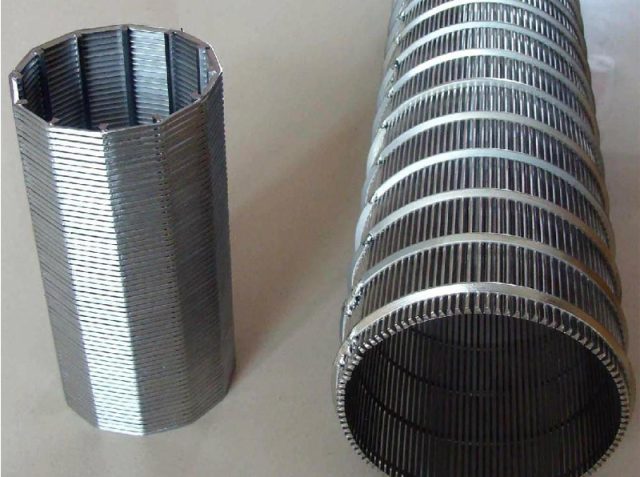

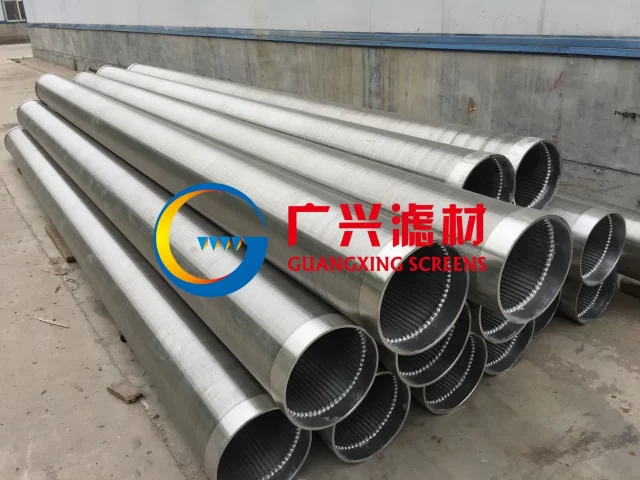

Well Screen Supply: Wedge Wire Screens for Sand Control in Water Wells

Wedge wire screens for sand control in water wells are essential tools for ensuring the longevity and efficiency of water wells. Made from high-quality stainless steel, these screens are durable, corrosion-resistant, and capable of filtering out sand and debris without clogging. Their customizable dimensions and slot sizes ensure they are suited for a wide range of applications, from municipal water supply systems to industrial geothermal wells. With their high mechanical properties, wedge wire screens provide reliable, long-lasting solutions for efficient groundwater extraction.

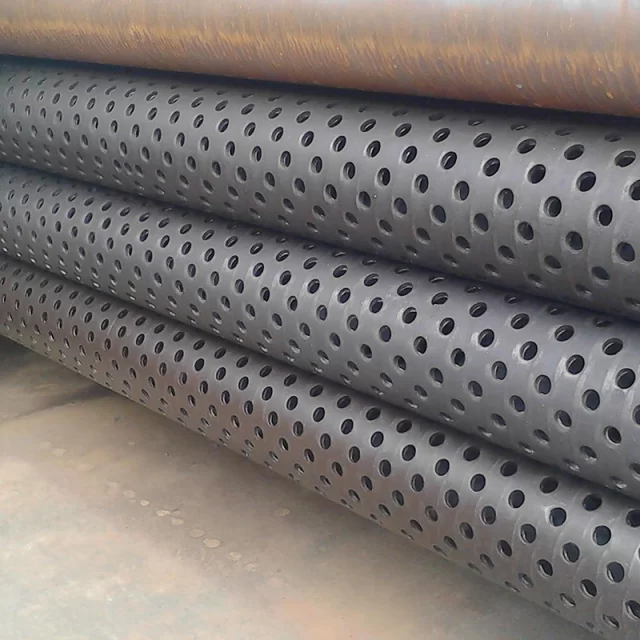

Perforated Casing Pipe: A Comprehensive Analysis of Products, Manufacturing, and Applications

Choosing the right perforated casing pipe requires careful consideration of factors such as formation characteristics, well depth, material strength, corrosion resistance, and regulatory requirements. When selected and installed properly, perforated casing pipes can significantly enhance production efficiency, ensure wellbore integrity, and minimize environmental impact.

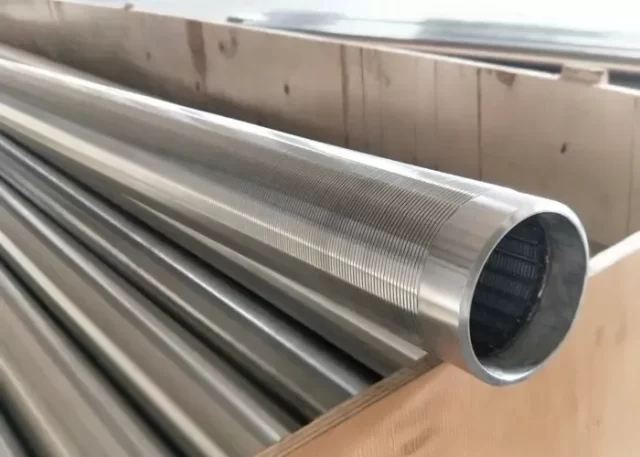

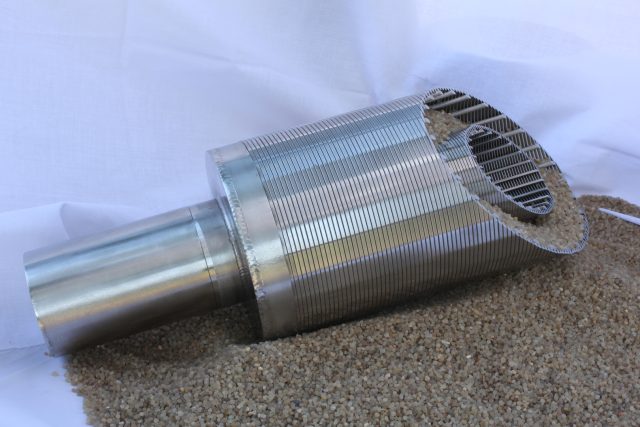

Analysis of Steel Pipe Base Well Screen

Steel pipe base well screens are a highly effective solution for filtration and sand control in modern oil and gas production wells. With their superior strength, accurate slot openings, and self-cleaning design, these screens offer significant advantages over other screen types like slotted liners. Their ability to handle sand-free production in both vertical and horizontal wells makes them a versatile choice for a wide range of well completion applications.

With customizable materials and specifications, pipe base screens provide an efficient, long-lasting solution for optimizing well productivity and ensuring the smooth operation of oil and gas production systems. As demands for increased production efficiency and enhanced sand control continue to grow, the importance of high-quality pipe base screens in well completions cannot be overstated.

Well Screens and Gravel Packs: Boosting Efficiency with Top Features & Superior Design

Learn how well screens and gravel packs improve productivity, offer sand-free operations, resist corrosion, and enhance efficiency with their advanced features and designs.

V-Wire Wedge Water Well Screen

Whether used in municipal water wells, oil and gas wells, or geothermal wells, stainless steel 304 V-wire wedge screens offer durability, corrosion resistance, and customizability, making them a reliable and cost-effective solution for well completion. By selecting the right slot size, material, and design, well operators can ensure that their wells operate efficiently and have a long service life.

Stainless Steel Water Well Screens

Stainless steel well screens are an essential component in a variety of industries, from water wells to oil and gas production. Their durability, corrosion resistance, and strength make them the material of choice for well screens in harsh environments. By selecting the right screen for your project and maintaining it properly, you can ensure optimal performance and longevity

For more information on stainless steel well screens, be sure to consult with a professional who can help guide you through the selection and design process

The Perforated Casing Pipe and What You Need to Know

Perforated casing pipes are indispensable components in various industries, providing essential support and fluid flow capabilities in well construction. Understanding their design, applications, and manufacturing processes is crucial for selecting the right pipe for specific needs. By considering factors such as well conditions, flow requirements, and corrosion resistance, operators can optimize the performance and longevity of perforated casing pipes. As technology continues to advance, new materials and manufacturing techniques will further enhance the capabilities of these vital components, ensuring their continued relevance in the ever-evolving landscape of drilling and well construction.

High Precision Wedge Wire Screen Filter Pipe

With these detailed characteristics and specifications, high precision wedge wire screen filter pipes offer reliable and efficient solutions for a wide range of industrial filtration needs. Their customizable features and durable construction ensure optimal performance in even the most demanding environments.

Johnson Wedge Wire Screen (V Wire Panel)

Johnson wedge wire screens (V wire panels) are a versatile and reliable solution for various industrial filtration applications. Their unique design, high efficiency, and durability make them suitable for use in water treatment, mining, food and beverage, pulp and paper, oil and gas, and architectural applications. Customizable slot sizes and dimensions ensure that these screens can meet specific filtration requirements, providing long-lasting and low-maintenance performance.

Galvanized Bridge Slot Screen Pipe

Galvanized Bridge Slot Screen Pipe is a reliable and efficient filtration solution that offers enhanced corrosion resistance and durability. With its bridge slots and galvanized coating, it provides optimal filtration performance while withstanding harsh environments. Whether it's for water wells, oil and gas operations, mining, or environmental protection, Galvanized Bridge Slot Screen Pipe is a valuable asset. Consider utilizing this specialized pipe for your filtration needs and experience its benefits in ensuring efficient and reliable filtration.

V Wire Wrap Well Screen Pipe: A Reliable Solution for Filtration

V Wire Wrap Well Screen Pipe offers a reliable and efficient solution for filtration needs. Its high-quality construction, precise slot design, and customizable options make it a versatile choice for various industries and applications. Whether it's for residential or industrial use, the V Wire Wrap Well Screen Pipe provides optimal flow rates, durability, and excellent filtration performance. Consider using V Wire Wrap Well Screen Pipe for your filtration needs and experience its benefits firsthand.

Sand Control Well Screen | Bridge Slotted Screen pipe

Bridge slotted screen pipes are a valuable tool in sand control for wells across different industries. Their ability to effectively prevent sand production, provide high flow rates, and maintain structural integrity makes them a preferred choice for many well operators. Whether it's an oil and gas well, a water well, or an environmental remediation project, bridge slotted screen pipes offer a versatile and reliable solution. Consult with a well professional to determine if bridge slotted screen pipes are suitable for your specific well needs and ensure the long-term productivity and efficiency of your well system.

When Should Replace well screen casing pipe ?

The wire wrapped screen from abterstee provides a reliable and effective method of preventing gravel-pack sand from entering the pipe, while allowing production fluids to flow into the well.The product acts as a sand-retaining device placed in the well. Compared to normal slotted tube, inflow area of the same opening sand screen mesh size is 30 times larger, which prolongs the well life.

Johnson Type Water Well Screens – Maximizing Water Well Performance with : Innovative Solutions for Reliable Water Supply

Johnson Type Water Well Screens offer various unit arrangements to accommodate different project needs. The protective shroud can be customized with perforations or louvers and is designed to accommodate a fiber-optic cable. The wire jacket is available in stainless steel or alloy/carbon steel material, and for special applications, a direct wrap option can be utilized, eliminating the need for welding to the base pipe. These features ensure the reliability and efficiency of Johnson Type Water Well Screens for a wide range of water well applications.

Johnson Stainless Steel Well Screens: Empowering Reliable and Efficient Water Wells

Advantages of Slot Wire Wrapped Water Well Screen Pipe

1. Better filter function

2. Prolong life of well

3. Long service life

4. High pressure-resistant

5. Customized Specifications

How to Clean a Stainless Steel Well Screen

Stainless Steel Water Well Screens and Accessories

abter well Screens is one of the largest manufacturers of stainless steel water well screens in the world. With a high open

area, allowing for better access to the entire formation around the screen; fines and drilling fluid are removed quickly

and completely, resulting in a better well development.

Custom Slot Well Screen Pipe | Slotted Perforated Well Screen for Casing

Product Continuous slot well screen, wire screen, Johnson screen Slot Size(mm) 0.10, 0.15, 0.2, 0.25, 0.30-3, also achieved upon customer request. Material Low Carbon ,Low Carbon Galvanized steel (LCG), Stainless Steel( 304,etc.) Lengths up to 6 meters Diameter 89 mm to 1200 mm End Connection Plain beveled ends, welding rings, flanges or threaded ( Thread...

Perforated Casing Pipe | Perforated Well Screen Piping

Applications of Perforated Pipe: Perforated well screen is a type of filter used in oil and gas wells. It is designed to control the flow of oil and gas from the well, while preventing sand and other debris from entering the well. perforation in the context of oil wells refers to a hole punched in...

Slotted Casing Pipe | Slotted Liner Well Screen – API 5CT

1. Introduction of Slotted Casing Pipe Casing pipe is a large-diameter pipe that serves as the structural retainer for the walls of oil and gas wells, or well bore. It is inserted into a well bore and cemented in place to protect both subsurface formations and the wellbore from collapsing and to allow drilling...

Well Screen Oil Casing , Pipe Based ,Sand Control,API 5CT

1. Grade: SUS 304 SUS304L, SUS316, SUS316L, or carbon steel 2. Slot Size: 0.02mm~15mm 3. Standard: DIN AISI ASTM 4. Certification: ISO9001, API 5CT 5.Pipe based well screens consist of base pipe,all-welded wedge wire screen and supporting rod.The base pipe is perforated or slotted API casing pipe,the base pipe can be stainless steel or carbon...

Pre-packed well screen | Wire Wrapped Pre Packed Sand Screen

Pre Packed Sand Screen contains perforated base pipe, inner and outer screen jackets and graded sand between the jackets. It is a modification of wire wrapped screen which is used in well sorted sand or stand-alone completion. Graded sand, with or without resin coating, is considered as a filter for reservoir particles. Wire wrapped pre...

Geothermal Pipe Based Screen | Sand Free Pipe Based Well Screen

PARAMETER Geothermal Pipe based well screen specification: Nominal Diameter Pipe OD(mm) Weight lb/ftW.T[mm] Hole size In Holes per foot Total Areaofholes in2/ft Screen OD (in) 2-3/8 60 4.6[4.83] 3/8 96 10.60 2.86 2-7/8 73 6.4[5.51] 3/8 108 11.93 3.38 3-1/2 88.9 9.2[6.45] 1/2 108 21.21 4.06 4 101.6 9.5[5.74] 1/2 120 23.56 4.55 4-1/2 114.3...

Water well screen pipe | Sand Control Screen

The water well screen is an important component of a well that allows water to flow into the well while preventing sediment and other debris from entering. The screen is typically located at the bottom of the well, near the aquifer. This is done to ensure that only clean water is collected and that...