1. Nota: DELES 304 SUS304L, SUS316, SUS316L, ou aço carbono

2. Tamanho do slot: 0.02mm ~ 15 mm

3. Padrão: DA AISI ASTM

4. Certificação: ISO 9001, API 5CT

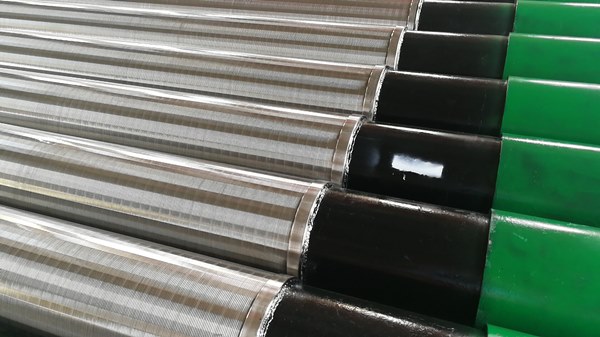

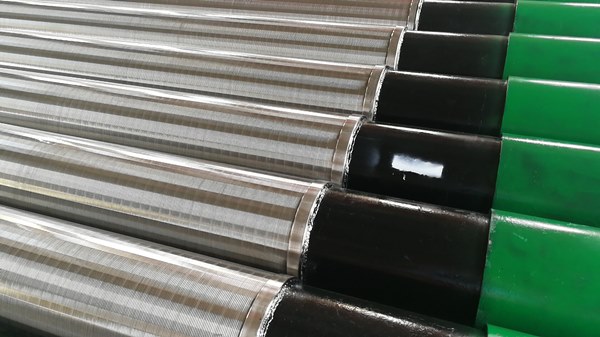

5.As telas de poço baseadas em tubos consistem em tubo de base,tela de arame em cunha totalmente soldada e haste de suporte. O tubo de base é um tubo de revestimento API perfurado ou com fenda,o tubo de base pode ser de aço inoxidável ou aço carbono API 5CT. As telas de arame em cunha totalmente soldadas são soldadas junto com o tubo de base pela haste de suporte.

6.Recursos de telas de poço baseadas em tubos:

1)Maior precisão de filtragem: telas de arame em cunha totalmente soldadas como revestimento de tela com design de abertura em V tornam a precisão da filtragem maior,que pode controlar melhor a areia.

2)Excelente resistência e resistência à deformação: O tubo base dentro,o exterior pode ser protegido com a jaqueta de proteção adicionada de acordo com os requisitos,a resistência integrada do tubo de base perfurado diminui apenas 2 a 3% em comparação com o revestimento padrão/tubulação de óleo,portanto, as telas de poço baseadas em tubos têm resistência integrada suficiente para resistir à pressão causada pelos estratos. Mesmo que alguma parte das telas de poço seja deformada,o slot desta parte não será ampliado,o que torna maior confiabilidade no controle de areia

3)Mais escolhas: o material da capa da tela pode ser aço inoxidável ou aço carbono,o material pode ser escolhido conforme a necessidade do cliente.

4)O slot menor aumentará a produção de petróleo e gás.

PARÂMETRO DE TUBO

Faixa de comprimento 6-13m

Padrão: API 5CT

Certificação: API 5CT, GOST, ISO 9001, ISO14001, OHSMS18000

Material: H40, M65, J55, K55, N80, L80, L90,C90,T95,P110,Q125, V150

Tipo de tópico: STC,LTC,Bitcoin,XC,NÃO,UE, Prémio XBY

|

4 1/2

|

114.30

|

11.60

|

17.26

|

J55 K55 N80

|

6.35

|

|

13.50

|

20.09

|

J55 K55 N80

|

7.37

|

|

5

|

127.00

|

15.00

|

22.32

|

J55 K55 N80

|

7.52

|

|

18.00

|

26.79

|

N80 P110

|

9.29

|

|

21.40

|

31.85

|

N80 P110

|

11.10

|

|

5-1/2

|

139.70

|

17.00

|

25.30

|

J55 K55 N80

|

7.72

|

|

20.00

|

29.76

|

N80

|

9.17

|

|

23.00

|

34.23

|

N80

|

10.54

|

|

7

|

177.80

|

23.00

|

34.23

|

J55 K55 N80

|

8.05

|

|

26.00

|

38.69

|

J55 K55 N80

|

9.19

|

|

29.00

|

43.16

|

N80

|

10.36

|

|

9-5/8

|

244.48

|

43.50

|

64.74

|

N80

|

11.05

|

|

47.00

|

69.94

|

N80

|

11.99

|

|

10-3/4

|

273.05

|

40.50

|

60.27

|

H40 J55 K55N80

|

8.89

|

|

51.00

|

75.90

|

J55 K55 N80

|

11.43

|

|

13-3/8

|

339.73

|

54.50

|

81.80

|

J55 K55

|

9.65

|

|

68.00

|

101.19

|

J55 K55 N80

|

12.19

|

|

16

|

406.40

|

65.00

|

96.73

|

J55 K55 N80

|

9.53

|

|

75.00

|

111.61

|

11.13

|

|

18-5/8

|

473.10

|

87.50

|

130.21

|

J55 K55 N80

|

11.05

|

O que é o invólucro de óleo de tela de poço API 5CT?

API 5CT tela bem invólucro de óleo é um tipo de equipamento de campo petrolífero usado para separar óleo, gás, água, e outros materiais do poço. É instalado dentro ou fora do poço para evitar que o fluido entre e danifique o ambiente circundante. É uma parte importante do sistema de produção do campo petrolífero.

O revestimento de óleo da tela de poço API 5CT é fabricado a partir de uma variedade de materiais, incluindo aço carbono, aço inoxidável, e ligas não corrosivas. O material utilizado depende da aplicação específica e do ambiente operacional. O revestimento é projetado para fornecer uma barreira resistente à pressão entre o poço e o ambiente circundante, bem como para evitar que fluidos e gases entrem no poço.

O revestimento de óleo de tela de poço API 5CT é normalmente instalado em uma variedade de configurações e tamanhos, dependendo do tipo de sistema de produção do campo petrolífero e do tamanho e formato do poço. A caixa pode ser reta ou cônica, dependendo do tipo de poço. A caixa também está disponível em vários tamanhos, de pequeno diâmetro a grande diâmetro, e é projetado para se adequar ao poço específico.

O revestimento de óleo de tela de poço API 5CT geralmente é instalado no poço por uma equipe de perfuração. O revestimento é então conectado ao equipamento de superfície, como a cabeça do poço, usando um cabide de revestimento. O suporte da carcaça é usado para segurar a carcaça no lugar e evitar que ela seja deslocada pelas forças do fluido. O revestimento é então conectado à cabeça do poço por meio de uma vedação de revestimento ou espaçador de revestimento, que sela a conexão entre o revestimento e a cabeça do poço.

Uma vez instalada a caixa, é testado para garantir que é capaz de suportar as pressões e temperaturas do sistema de produção do campo petrolífero. Isso é feito usando um teste de pressão, que mede a pressão e a temperatura do fluido dentro do poço. Se o invólucro falhar neste teste, ele deve ser removido e substituído.

O revestimento de óleo de tela de poço API 5CT foi projetado para fornecer uma barreira confiável e durável entre o poço e o ambiente circundante. Ele também foi projetado para evitar que o fluido entre no poço e danifique o ambiente circundante.. O revestimento é normalmente fabricado para atender aos requisitos específicos do sistema de produção do campo petrolífero e ao tamanho e formato do poço.

Depois que o invólucro estiver instalado, é testado para garantir que pode suportar as pressões e temperaturas do sistema de produção do campo petrolífero. O revestimento é então conectado ao equipamento de superfície, como a cabeça do poço, por meio de um suporte de caixa. O suporte da carcaça é usado para segurar a carcaça no lugar e evitar que ela seja deslocada pelas forças do fluido. O revestimento é então conectado à cabeça do poço por meio de uma vedação de revestimento ou espaçador de revestimento, que sela a conexão entre o revestimento e a cabeça do poço.

Depois que o invólucro estiver instalado e testado, é inspecionado quanto a quaisquer danos ou defeitos. Se algum dano ou defeito for encontrado, a carcaça deve ser substituída. A carcaça também deve ser inspecionada quanto a quaisquer sinais de corrosão ou desgaste. Se forem encontrados quaisquer sinais de corrosão ou desgaste, a carcaça deve ser substituída.

O revestimento de óleo da tela de poço API 5CT é um componente importante do sistema de produção de campos petrolíferos. Fornece uma barreira confiável e durável entre o poço e o ambiente circundante, bem como evitar que fluidos e gases entrem no poço. O revestimento é normalmente fabricado para atender aos requisitos específicos do sistema de produção do campo petrolífero e ao tamanho e formato do poço. Além disso, o revestimento geralmente é testado para garantir que seja capaz de suportar as pressões e temperaturas do sistema de produção do campo petrolífero.

Postagens relacionadas

Tubo de tela de poço de água | Tela de controle de areia

A tela do poço de água é um componente importante de um poço que permite que a água flua para dentro do poço, evitando a entrada de sedimentos e outros detritos. A tela normalmente está localizada na parte inferior do poço, perto do aquífero. Isto é feito para garantir que apenas água limpa seja coletada e que qualquer sedimento ou sujeira seja filtrado.. A tela é normalmente feita de um tubo perfurado ou outro tipo de material que possui pequenas aberturas para permitir a passagem da água enquanto bloqueia a entrada de sedimentos. A tela Abter Well é fabricada com uma fenda contínua em forma de V para reduzir a velocidade de entrada da água e as taxas de incrustação. Além do mais, A tela do poço Filson tem uma grande área de superfície sem obstruir, proporcionando assim um desempenho de filtragem superior. A seleção do tamanho do slot da tela é uma etapa crítica, normalmente com base na análise de tamanho de partícula da amostra de formação. Com a faixa de tamanho de slot padrão de 0,005” a 0,5”, A tela do poço Filson pode controlar perfeitamente partículas de areia e lodo do poço. Vantagens das telas de poço de água 1. O plano de seção em forma de V das telas de poços de água cria a fenda contínua, o que pode evitar o bloqueio e garantir a água desimpedida. Consulte Mais informação

Tela baseada em tubo geotérmico | Tela de poço baseada em tubo sem areia

Especificação de tela de poço baseada em tubo geotérmico PARÂMETRO: Diâmetro nominal do tubo OD(milímetros) Peso lb/ftW.T[milímetros] Tamanho do furo em furos por pé Área total de furos em 2/pés OD da tela (em) 2-3/8 60 4.6[4.83] 3/8 96 10.60 2.86 2-7/8 73 6.4[5.51] 3/8 108 11.93 3.38 3-1/2 88.9 9.2[6.45] 1/2 108 21.21 4.06 4 101.6 9.5[5.74] 1/2 120 23.56 4.55 4-1/2 114.3 11.6[6.35] 1/2 144 28.27 5.08 5 127 13[6.43] 1/2 156 30.63 5.62 5-1/2 139.7 15.5[6.99] 1/2 168 32.99 6.08 6-5/8 168.3 24[8.94] 1/2 180 35.34 7.12 7 177.8 23[8.05] 5/8 136 42.16 7.58 7-5/8 194 26.4[8.33] 5/8 148 45.88 8.20 8-5/8 219 32[8.94] 5/8 168 51.08 9.24 9-5/8 244.5 36[8.94] 5/8 188 58.28 10.18 10-3/4 273 45.5[10.16] 5/8 209 64.79 11.36 13-3/8 339.7 54.5[9.65] 5/8 260 80.60 14.04 O que é tela de poço geotérmico? As telas de poço geotérmico são um componente essencial de um sistema de poço geotérmico. Eles são usados para filtrar e proteger o poço geotérmico contra detritos e outros contaminantes que podem ser prejudiciais ao sistema.. As telas de controle de areia são projetadas para serem duráveis e confiáveis, fornecendo proteção de longo prazo para o poço. A tela de poço geotérmico é um tubo cilíndrico feito de metal perfurado ou material plástico. As perfurações são projetadas para permitir Consulte Mais informação

Tela bem pré-embalada | Tela de areia pré-embalada enrolada em fio

Tela de areia pré-embalada contém tubo de base perfurado, revestimentos de tela internos e externos e areia graduada entre os revestimentos. É uma modificação da tela enrolada em arame que é usada em areia bem selecionada ou completação autônoma. Areia graduada, com ou sem revestimento de resina, é considerado um filtro para partículas do reservatório. A tela de areia pré-embalada pré-embalada é usada em poços onde o empacotamento convencional de cascalho não é viável ou econômico. A espessura da camada de cascalho pode ser variada para atender a requisitos especiais. Qual é a função do pacote de cascalho? O empacotamento de cascalho é uma das técnicas populares de controle de areia usadas em petróleo, poços de água e gás. Estabiliza o furo e filtra a areia do fluxo, permitindo apenas partículas muito finas. Tela de areia pré-embalada A tela de areia enrolada em arame coloca-a em ação total na maximização da produção, bem como no controle da areia. Diâmetro: 168mm Material: aço inoxidável,Aço carbono,etc Slot: 0.2mm Conexão final: fio,acoplamento,etc espessura: 10Tela de areia pré-embalada mm ESPECIFICAÇÕES DO PRODUTO Tela de perfuração de pacote de cascalho de tubo base OD (em.) ID (em.) Peso (libras.) DE do acoplamento (em.) Espessura (em.) Tamanho (em.) Furos/pés. DE (em.) Área do Cilindro (quadrado. pol./pé) 006 Área de entrada GA (quadrado. pol./pé) 1.9 1.61 2.75 Consulte Mais informação

Tubo de revestimento com fenda | Tela de poço de revestimento com fenda – API 5CT

1. Introdução do tubo de revestimento com fenda O tubo de revestimento é um tubo de grande diâmetro que serve como retentor estrutural para as paredes de poços de petróleo e gás, ou poço perfurado. Ele é inserido em um poço e cimentado no local para proteger as formações subterrâneas e o poço contra o colapso e para permitir que o fluido de perfuração circule e a extração ocorra. O tubo de revestimento com fenda é um tipo de tubo de revestimento que possui ranhuras usinadas em sua superfície. Essas ranhuras são usadas para ajudar a controlar o fluxo de água, óleo, e gás em um poço. O tubo de revestimento com fenda foi projetado para permitir que a água, óleo, e gás fluam através das ranhuras, evitando que areia e outros detritos entrem no poço. O tubo de revestimento com fenda é comumente usado em poços de petróleo e gás, poço de água, e poços geotérmicos. 2. Tipos de tubo de revestimento com fenda Existem dois tipos principais de tubo de revestimento com fenda: slot aberto e slot perfurado. O tubo de revestimento com ranhura aberta possui ranhuras que são cortadas na superfície do tubo em linha reta. Esses slots geralmente são espaçados uniformemente e normalmente têm cerca de 1/4 polegada de largura e 1/4 polegada de profundidade. Slot perfurado Consulte Mais informação

Tubo de revestimento perfurado | Tubulação de tela de poço perfurada

Aplicações de tubo perfurado: A tela de poço perfurado é um tipo de filtro usado em poços de petróleo e gás. Ele é projetado para controlar o fluxo de petróleo e gás do poço, evitando que areia e outros detritos entrem no poço. perfuração no contexto de poços de petróleo refere-se a um furo feito no revestimento ou revestimento de um poço de petróleo para conectá-lo ao reservatório. Criar um canal entre a zona de pagamento e o poço para fazer com que o petróleo e o gás fluam facilmente para o poço. Em completações de furos revestidos, o poço será perfurado além da seção da formação desejada para produção e terá revestimento ou revestimento separando a formação do furo do poço. A etapa final da conclusão envolverá a execução de canhões perfurantes, uma série de cargas moldadas, até a profundidade desejada e disparando-os para perfurar o revestimento ou revestimento. Uma arma de perfuração típica pode transportar dezenas de cargas explosivas. Geralmente, as armas de perfuração funcionam na linha E, pois é tradicional usar sinais elétricos da superfície para disparar as armas. Em poços mais altamente desviados, tubulação espiralada pode ser usada. Tecnologias mais recentes Consulte Mais informação

Tubo de tela de poço de slot personalizado | Tela de poço perfurado com fenda para revestimento

Produto Tela contínua de slot bem, tela de arame, Tamanho do slot da tela Johnson(milímetros) 0.10, 0.15, 0.2, 0.25, 0.30-3, também alcançado mediante solicitação do cliente. Material Baixo Carbono ,Aço galvanizado de baixo carbono (LCG), Aço inoxidável( 304,etc.) Comprimentos até 6 metros de diâmetro 89 mm para 1200 mm Conexão final Extremidades chanfradas lisas, anéis de soldagem, flanges ou roscados ( Acoplamento rosca macho/fêmea ) . Os dados apenas para referência, podemos projetá-lo como o pedido do cliente. A tela de poço de ranhura contínua é feita por um fio laminado a frio enrolado em V ou em cunha em torno de uma matriz interna de hastes de suporte longitudinais. A tecnologia totalmente soldada mundialmente avançada é usada em cada ponto de interseção desses fios soldados por fusão, o que cria a construção robusta e excelente desempenho mecânico. O fio de perfil em forma de v ou cunha envolve as hastes de suporte em todo o comprimento da tela, criando uma abertura de fenda contínua, portanto, a tela permite que água ou óleo entrem livremente em seu poço em grandes quantidades, ao mesmo tempo que mantém a maior parte da areia e cascalho fora do poço. Todas as ranhuras devem estar limpas e livres de rebarbas e cortes e podem ser trocadas de acordo com a necessidade do cliente. Aplicativo: Para água, poços de petróleo e gás, principalmente indústria de poços de água. Consulte Mais informação