1. Introduction of Slotted Casing Pipe

Casing pipe is a large-diameter pipe that serves as the structural retainer for the walls of oil and gas wells, or well bore. It is inserted into a well bore and cemented in place to protect both subsurface formations and the wellbore from collapsing and to allow drilling fluid to circulate and extraction to take place.

Slotted casing pipe is a type of casing pipe that has slots machined into its surface. These slots are used to help control the flow of water, oil, and gas in a well bore. The slotted casing pipe is designed to allow water, oil, and gas to flow through the slots while preventing sand and other debris from entering the well bore. Slotted casing pipe is commonly used in oil and gas wells, water wells, and geothermal wells.

2. Types of Slotted Casing Pipe

There are two main types of slotted casing pipe: open slot and perforated slot. Open slot casing pipe has slots that are cut into the surface of the pipe in a straight line. These slots are usually spaced evenly apart and are typically about 1/4 inch wide and 1/4 inch deep. Perforated slot casing pipe has slots that are punched into the pipe in a circular pattern. These slots are typically about 3/8 inch in diameter and 1/4 inch deep.

3. Benefits of Slotted Casing Pipe

Slotted casing pipe has several benefits over other types of casing pipe. The slots in the pipe allow for increased fluid flow, which helps to reduce the pressure on the formation and the well bore. This can help to prevent the formation from collapsing, which can lead to costly repairs or even well abandonment. The slots also act as a filter, preventing sand and other debris from entering the well bore, which can damage the pump and reduce the production rate of the well.

4. Applications of Slotted Casing Pipe

Slotted casing pipe is used in a variety of different applications. It is commonly used in oil and gas wells, water wells, and geothermal wells. It is also used in tunnels and underground chambers, such as those used for storing hazardous materials or for mining operations. Slotted casing pipe can even be used in agricultural applications, such as for irrigation or drainage.

5. Advantages of Slotted Casing Pipe

Slotted casing pipe has several advantages over other types of casing pipe. It is extremely durable and can withstand high pressure and temperatures. It is also easy to install and can be adapted to fit any size well bore. The slots in the casing pipe also help to reduce the amount of time and money spent on well repairs, as they can reduce the pressure on the formation and prevent sand and other debris from entering and damaging the pump.

7. Conclusion

Slotted casing pipe is a type of casing pipe that has slots machined into its surface. These slots are used to help control the flow of water, oil, and gas in a well bore and can also act as a filter, preventing sand and other debris from entering the well bore. Slotted casing pipe is used in a variety of different applications, including oil and gas wells, water wells, and geothermal wells. It has many benefits, such as increased fluid flow, reduced pressure on the formation, and prevention of sand and debris entering the well bore.

Main technical data:

Material: stainless steel, carbon steel

Categories of pipes: petroleum casing pipe, oil pipe

Length of pipe (single): ≤15m

Outside diameter of pipe: 50 to 200mm

Wall thickness ≤16mm

Width of slot: (0.10-0.40)mm±0.03mm

Number of slots: according to order

Distribution types of slots: parallel, crisscross, spiral

Distance of slots: according to order

Slotted Liner Well Screen

Technical Details:

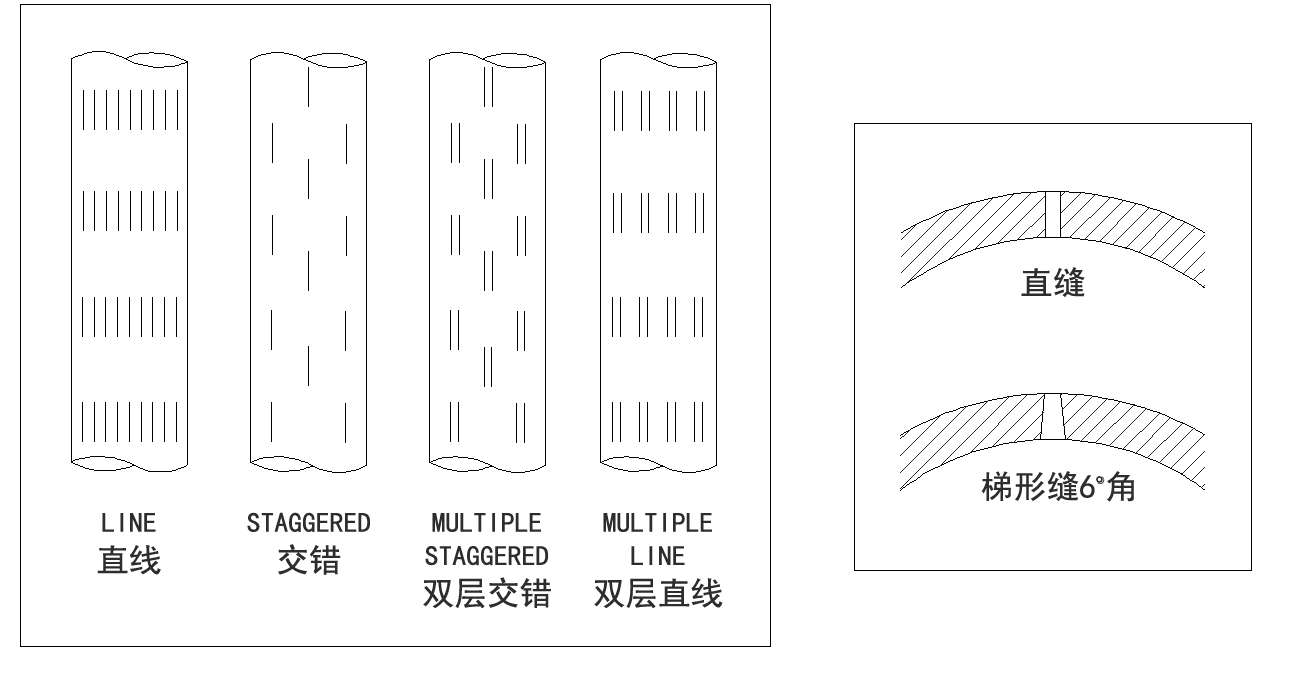

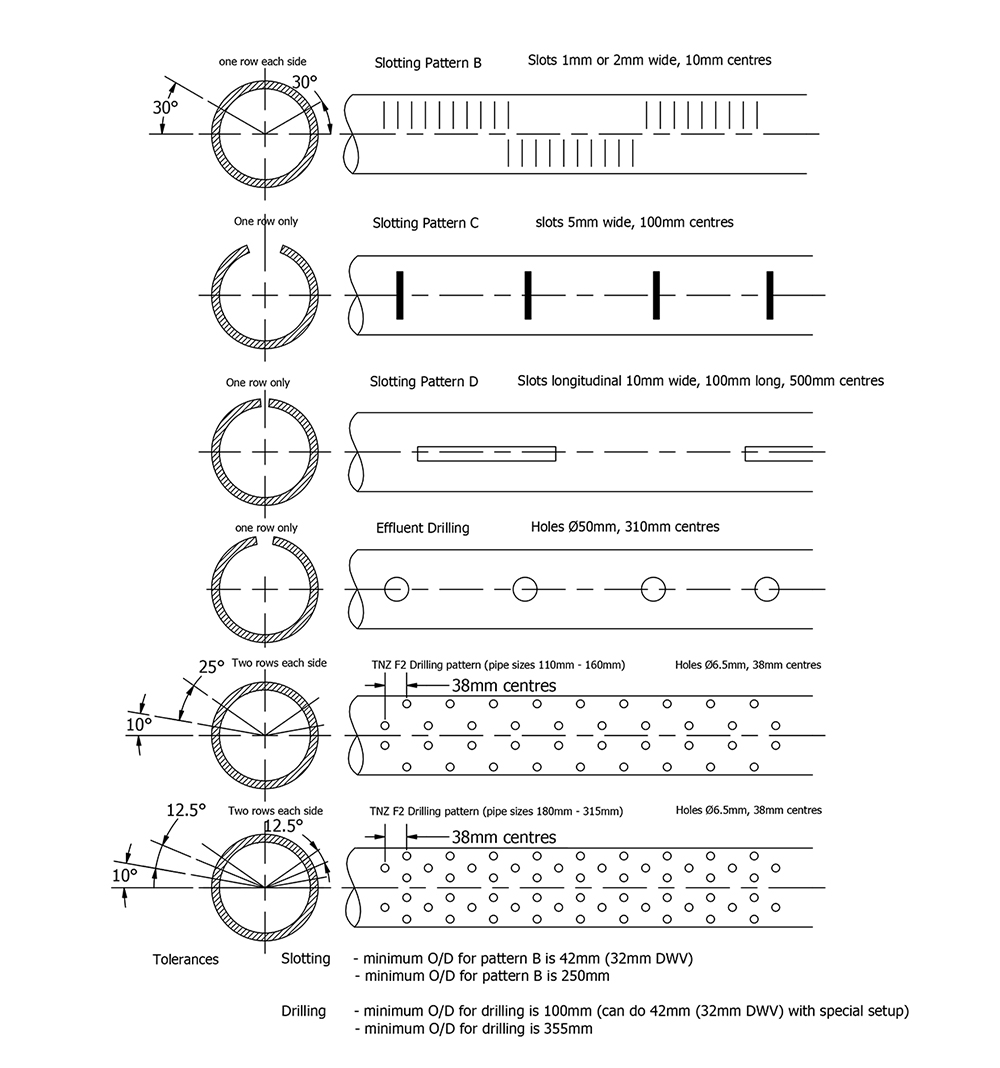

Slotted liner patterns illustration:

Three slot patterns are designed for different characteristics (shown below). Compared to staggered and straight slot patterns, gang slot pattern has superiorities over installation torque-loading capacity and substantially improves the liner’s resistance to lateral bucking and collapse pressures.

| Slotted Liner Patterns | ||

| Staggered Slotted Liner | Gang Slotted Liner | Straight slotted liner |

|

|

|

| Staggered slots features alternate slot evenly spaced around the circumference with offset. | Gang slots feature multiple slots evenly spaced around circumference in a staggered pattern. | Straight slotted liner features slot columns spaced evenly around the circumference without offset. |

Slot profiles

Slot profile poses great importance on sand control and plugging performance. According to its different geometry, there are two slots – straight cut slot and seamed keystone slot. In almost horizontal completions in SAGD, seamed keystone slot performs much better than typical straight cut slot, and cost a little more.

| Slot Shapes | |

| Straight Cut Slot | Seamed Keystone Slot |

|

|

| Straight cut slots are designed for the same width through ID to OD. Straight slots feature more wear-resistant than seamed keystone slot. | Seamed keystone slot – width at the liner surface is narrower than width on the pipe interior. It features anti-plugging and self-cleaning. |

Slot density

Slot density refers to the number of slots per foot of pipe. It is determined by the open area of the pipe’s outer surface. Open area is an important factor of reducing the sand control capacity of a slotted liner. Generally speaking, open area ranges from 2% to 4%.

When the open area, the slot width and the diameter of the liner are determined, the slot density per foot can be calculated by the following formula:

| N = | 12πD C |

| 100 W L |

N stands for slot density or the number of slots per foot

D stands for outside diameter of the liner in inch

C stands for open area, percentage

W stands for slot width in inch

L stand for the length of slot in inch

Example: For a 4.5” slotted liner, its open area is 3%, the slot width is 0.02 inch, the slot length is 1.5’, so what is the number of slot per foot?

According to the formula above, the required Number of slots is shown below:

| N = | 12×π×4.5×3 | = 172 |

| 100×0.020×1.5 |

Note: This formula is just a conventional calculation for either straight slot or seamed keystone slot.

Adverse factors on plugging of slotted liner.

Anti-plugging is a vital element for the evaluation of slotted liners. Four factors which are probably cause plugging are found.

Slot Profile

It is proven by more and more living examples that seamed keystone slot is superior to straight slot.

Formation wettability influence on slot plugging and sand production is especially apparent when the wetting phase is in motion.

Clay concentration

Usually, clay is the main factor of slot plugging. When both granular sand and clay are present, the possibility of severe plugging is extraordinarily high.

Fluid pH is another important factor of slot plugging. Lower pH working conditions have less plugging problems. HCl solution is a good resolution of removing existing plugs.

| Standard | Grade | Chemical compositions(%) | |||||||||

| API SPEC 5CT | J55 | C | Si | Mn | P | S | Cr | Ni | Cu | Mo | V |

| K55 | 0.34~0.39 | 0.20~0.35 | 1.25~1.50 | ≤0.020 | ≤0.015 | ≤0.15 | ≤0.20 | ≤0.20 | / | / | |

| N80 | 0.34~0.38 | 0.20~0.35 | 1.45~1.70 | ≤0.020 | ≤0.015 | ≤0.15 | / | / | / | 0.11~0.16 | |

| L80 | 0.15~0.22 | ≤1.00 | 0.25~1.00 | ≤0.020 | ≤0.010 | 12.0~14.0 | ≤0.20 | ≤0.20 | / | / | |

| P110 | 0.26~0.395 | 0.17~0.37 | 0.40~0.70 | ≤0.020 | ≤0.010 | 0.80~1.10 | ≤0.20 | ≤0.20 | 0.15~0.25 | ≤0.08 | |

Mechanical Properties

| Grade | Type | Total elongation under load (%) | Yield strength (min) | Yield strength (max) | Tensile strength min Mpa | Hardness Max (HRC) | Hardness Max(HBW) |

| J55 | – | 0.5 | 379 | 552 | 517 | – | – |

| K55 | – | 0.5 | 379 | 552 | 655 | – | – |

| N80 | 1 | 0.5 | 552 | 758 | 689 | – | – |

| N80 | Q | 0.5 | 552 | 758 | 689 | – | – |

| L80 | 1 | 0.5 | 552 | 655 | 655 | 23 | 241 |

| L80 | 9Cr | 0.5 | 552 | 655 | 655 | 23 | 241 |

| L80 | 13Cr | 0.5 | 552 | 655 | 655 | 23 | 241 |

| C90 | – | 0.5 | 621 | 724 | 689 | 25.4 | 255 |

| C95 | – | 0.5 | 655 | 758 | 724 | – | – |

| T95 | – | 0.5 | 655 | 758 | 724 | 25.4 | 255 |

| P110 | – | 0.6 | 758 | 965 | 862 | – | – |

| Q125 | All | 0.65 | 862 | 1034 | 931 | – | – |

| API Casing pipe |

ID |

Length |

Slot Length |

Slot No. |

Slot width |

Slot |

Valid Filter |

Max. |

||

|

Spec mm |

Thickness |

Per Weight |

||||||||

|

60.32 |

5 |

6.84 |

50.3 |

3 |

80 |

200 |

0.3 |

±50 |

48 |

512.54 |

|

73.02 |

5.5 |

9.15 |

62 |

240 |

57.6 |

688.55 |

||||

|

88.9 |

6.5 |

13.22 |

75.9 |

280 |

67.2 |

995.1 |

||||

|

101.6 |

6.5 |

15.22 |

88.6 |

300 |

72 |

1151.2 |

||||

|

114.3 |

7 |

18.47 |

100.3 |

10 |

320 |

76.8 |

1400.4 |

|||

|

127 |

7.52 |

22.13 |

112 |

340 |

81.6 |

1673.8 |

||||

|

139.7 |

7.72 |

25.11 |

124.3 |

360 |

86.4 |

1900.2 |

||||

|

9.17 |

29.48 |

121.4 |

360 |

86.4 |

2232.4 |

|||||

|

168.3 |

8.94 |

35.09 |

150.4 |

400 |

96 |

2672.95 |

||||

|

177.8 |

8.05 |

33.68 |

161.7 |

440 |

105.6 |

2559.2 |

||||

|

9.19 |

38.19 |

159.4 |

440 |

105.6 |

2940.7 |

|||||

| Sreen pipe dimension (in) | OD(mm) | Wall thickness(mm) | ID (mm) | Stitch number of each circle | Slot width(mm) | Slot length (mm) | Length(mm) |

| 2-3/8″ | 60.3 | 4.83 | 50.64 | 12~18 | 0.2~0.8 | 45~100 | 1000~12000 |

| 2-7/8″ | 73 | 5.51 | 61.98 | 20~24 | 45~100 | ||

| 3-1/2″ | 88.9 | 6.45 | 76 | 24~28 | 45~100 | ||

| 4″ | 101.6 | 6.65 | 88.29 | 24~30 | 45~100 | ||

| 4-1/2″ | 114.3 | 5.69 | 102.92 | 24~30 | 45~100 | ||

| 6.35 | 101.6 | 45~100 | |||||

| 7.37 | 99.57 | 45~100 | |||||

| 8.56 | 97.18 | 45~100 | |||||

| 5″ | 127 | 5.59 | 115.82 | 28~36 | 0.25~0.8 | 45~100 | |

| 6.43 | 114.15 | 45~100 | |||||

| 7.52 | 111.96 | 45~100 | |||||

| 9.19 | 108.61 | 45~100 | |||||

| 5-1/2″ | 139.7 | 6.2 | 127.3 | 30~38 | 45~100 | ||

| 6.99 | 125.73 | 45~100 | |||||

| 7.72 | 124.26 | 45~100 | |||||

| 9.17 | 121.36 | 45~100 | |||||

| 10.54 | 118.62 | 45~100 | |||||

| 7″ | 177.8 | 6.91 | 163.98 | 36~50 | 45~100 | ||

| 8.05 | 161.7 | 45~100 | |||||

| 9.19 | 159.41 | 45~100 | |||||

| 10.36 | 157.07 | 45~100 |

1. Our perforated pipe use J55/K55/N80 casing and tubings of API standard, with High overall strength, not so easy to deformation.

2. The edge of the slot is vertical, smooth, without burrs, and the slot is uniformity.

3. The perforated pipe is suitable for sandy well, which the diameter of the sand greater than 0.3mm.

4. The slot can be longitudinal and transverse, the section of the slot can be parallel and trapezoidal types, with a wide open area.

5. Slotted screen pipe has a big inner diameter.