Piling Pipes: The Unsung Heroes of Construction

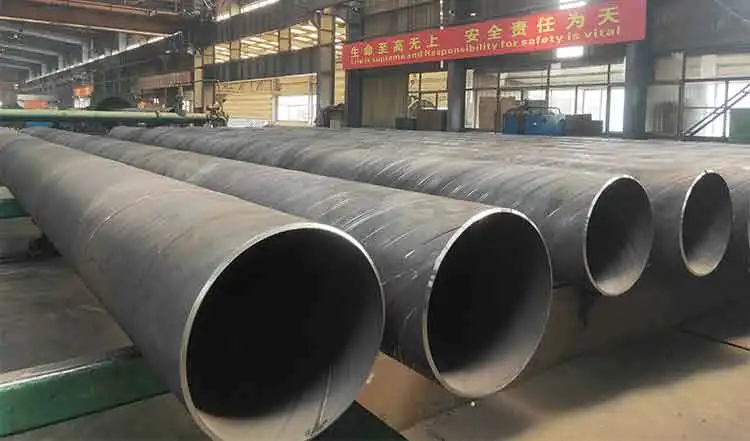

Piling pipes, often overlooked, play a crucial role in modern construction. These unassuming elements have revolutionized how we establish strong foundations for various projects. From towering skyscrapers to humble residential structures, piling pipes have become the backbone of construction endeavors, providing reliability and durability.

In this article, we will explore the world of piling pipes, discussing their versatile applications, the driving factors behind their adoption, and the significant benefits they bring to construction projects of all sizes. Through the expertise of dedicated piling pipe suppliers, we will uncover the pivotal role of piling pipes and recognize why they have become an indispensable asset in contemporary construction practices.

|

Material

|

Q195, Q235,Q345,X42, X52,X60 and so on

|

|

Standard

|

API,ASTM A53,bs,API5L,ASTM A500,ASTMA501,EN10219,EN10210,GB/T6728,GB/T9711,GB/T3094,GB/T3091,JIs G3466

|

|

Shape

|

round

|

|

Thickness

|

5mm – 28mm

|

|

Length

|

3-12m

|

|

External diameter

|

219mm – 2020mm

|

|

Certification

|

API

|

|

Technology

|

|

The Building Blocks Of Modern Infrastructure: Uses Of Piling Pipes

Gone are the days when traditional foundation techniques were the only option. Piling pipes have carved a niche for themselves in numerous settings. They are commonly used in large-scale construction projects such as skyscrapers, bridges, and offshore platforms. They are also prevalent in small residential structures that require a sturdy foundation, especially in challenging soil conditions. Thanks to piling pipe suppliers, these materials have become more accessible, making them ubiquitous in various construction endeavors.

What Drives Their Use?

There are several reasons why piling pipes have become a staple in construction. Firstly, they offer unparalleled strength and durability, providing solid foundations that stand the test of time. Secondly, they can be easily driven into the ground, making the installation process swift and efficient. They are especially valuable when the existing soil conditions are less than ideal, as they can bypass weaker soil layers and rest on more robust ground.

More Than Just Metal: Qualities Stated By Piling Pipe Suppliers

While piling pipes can be made from various materials, steel piles have an edge in terms of strength and durability. Steel is highly resistant to rot, corrosion, and insect damage, making it a popular choice among reputable piling pipe suppliers and contractors. These qualities make steel piles a long-term investment, resulting in reduced maintenance and repair costs over the years.

The Unseen Benefits Of Using Piling Pipes

Let’s break down the significant benefits of using piling pipes in construction projects:

- Enhanced Bearing Capacity: The bearing capacity of the foundation is crucial for any construction project. Piling pipes offer superior bearing capacity, ensuring structures remain secure and stable for an extended period.

- Penetrating Stiff Layers or Boulders: Piling pipes can penetrate through hard layers of soil or even boulders, ensuring that the foundation rests on firm ground. This attribute makes them indispensable in regions with rocky or inconsistent soil compositions.

- Minimizing Soil Displacement: Piling pipes result in minimal soil displacement during installation. This feature is essential in crowded urban areas where space is limited, making piling pipes an eco-friendly and less disruptive option.

- Robust And Reliable: Withstanding Rough Handling: Construction sites can be harsh environments where materials need to withstand considerable abuse. Piling pipes endure rough handling, ensuring they retain their structural integrity throughout installation.

Opting For The Best: How To Choose Your Piling Pipe Supplier

Selecting the right supplier is as crucial as choosing the right materials. With the surge in demand for piling pipes, multiple suppliers have entered the market, offering a range of products that may vary in quality and cost. Here are a few factors to consider when making your selection:

- Quality Assurance: Choose a supplier that offers quality assurance through certifications or product testing. Poor-quality piling pipes can undermine the integrity of your entire project.

- Material Options: Look for a supplier that provides diverse options, whether you’re interested in steel or another material, to meet your specific needs.

- Customer Service: An effective piling pipe supplier should provide excellent customer service, from initial inquiry to final delivery. Communication is vital in any construction project, and a supplier committed to customer service will likely be a reliable partner in your endeavor.

- Competitive Pricing: While quality should never be compromised, consider the pricing offered by different suppliers. Ensure that the cost aligns with your budget without sacrificing quality.

In conclusion, piling pipes are the unsung heroes of construction, playing a crucial role in establishing strong foundations for various projects. Their versatility, strength, and durability make them an indispensable asset in modern construction practices. By choosing the right piling pipe supplier and understanding the benefits they bring, you can ensure the success and longevity of your construction projects.

The use of pipe piles in foundation construction has been a popular choice for many years. Pipe piles are used to transfer the load of a structure to a deeper, more stable layer of soil or rock.

Benefits of Pipe Trusses The use of pipe trusses in construction offers several notable advantages: Strength and Load-bearing Capacity: Pipe trusses are renowned for their high strength-to-weight ratio. The interconnected pipes distribute loads evenly, resulting in a sturdy and reliable structure. This allows for the construction of large spans without the need for excessive support columns or beams.

The standard for fluid-conveying seamless pipes depends on the country or region you are in, as well as the specific application. However, some widely used international standards for fluid-conveying seamless pipes are: ASTM A106: This is a standard specification for seamless carbon steel pipes for high-temperature service in the United States. It is commonly used in power plants, refineries, and other industrial applications where high temperatures and pressures are present. It covers pipes in grades A, B, and C, with varying mechanical properties depending on the grade. API 5L: This is a standard specification for line pipes used in the oil and gas industry. It covers seamless and welded steel pipes for pipeline transportation systems, including pipes for conveying gas, water, and oil. API 5L pipes are available in various grades, such as X42, X52, X60, and X65, depending on the material properties and application requirements. ASTM A53: This is a standard specification for seamless and welded black and hot-dipped galvanized steel pipes used in various industries, including fluid-conveying applications. It covers pipes in two grades, A and B, with different mechanical properties and intended uses. DIN 2448 / EN 10216: These are European standards for seamless steel pipes used in fluid-conveying applications, including water, gas, and other fluids. Read more

Fluid-conveying seamless pipes are designed to resist various types of corrosion depending on the material used and the specific application. Some of the most common types of corrosion that these pipes are designed to resist include: Uniform corrosion: This is the most common type of corrosion, where the entire surface of the pipe corrodes uniformly. To resist this type of corrosion, pipes are often made of corrosion-resistant materials, such as stainless steel or lined with protective coatings. Galvanic corrosion: This occurs when two dissimilar metals are in contact with each other in the presence of an electrolyte, leading to the corrosion of the more active metal. To prevent galvanic corrosion, pipes can be made of similar metals, or they can be isolated from each other using insulating materials or coatings. Pitting corrosion: Pitting is a localized form of corrosion that occurs when small areas on the pipe's surface become more susceptible to attack, leading to the formation of small pits. This type of corrosion can be prevented by using materials with high pitting resistance, such as stainless steel alloys with added molybdenum, or by applying protective coatings. Crevice corrosion: Crevice corrosion occurs in narrow spaces or gaps between two surfaces, such Read more

Wedge wire screens, also known as profile wire screens, are commonly used in various industries for their superior screening capabilities. They are constructed from triangular-shaped wire,

2 7/8in J55 K55 Perforated Well Casing Pipe is one of mainly products of we abter steel, they can be used for water, oil, gas well drilling fields. The thicknesss can be supplied from 5.51-11.18mm based on client's well depth and required mechanical properties. Normally they are provided with thread connection, like NUE or EUE, which will be easier to installed at site. The length of 3-12m perforated casing pipes are available for client's different drilling rigs height. The hole diameter and open area on the surface are also customized. The popular hole diameters are 9mm, 12mm, 15mm, 16mm, 19mm, etc.