Steel Pipe for Friction Pile: An Overview

Steel pipe piles are commonly used in construction projects, particularly in foundation systems such as friction piles. Friction piles rely on the frictional resistance between the pile and the surrounding soil to transfer the load to the ground. In this article, we will explore the use of steel pipe for friction piles, its advantages, specifications, and considerations for design and installation.

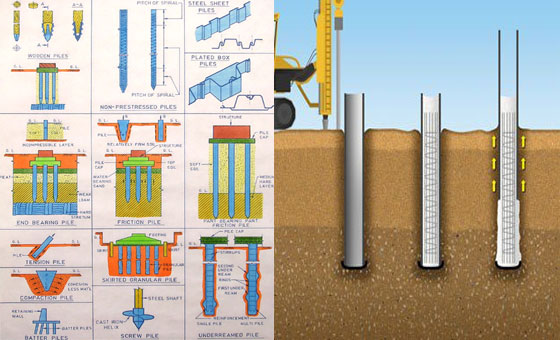

Friction piles, also known as floating piles, are an underground piling system designed to create a solid foundation for large structures like bridges, roads, and stadiums. These structures require a foundation that the topsoil alone cannot support. Friction piles rely on the frictional resistance between the pile surface and the surrounding soil to transfer the load of the superstructure. It is crucial for the friction force to be sufficient to ensure a strong and stable foundation.

Friction piles are commonly used for large structures and in situations where the soil may experience excessive settlement. These piles maximize their bearing capacity through shear stresses along the sides of the pile, making them particularly effective in complex soil layers that are economically challenging to reach. By relying on skin friction, friction piles effectively bear the load of the superstructure. They are typically constructed using long and slender elements, similar to columns. Materials such as steel, reinforced concrete, and even timber can be used to form friction piles. The length of the pile is usually at least three times the width of the structure and extends below the structure to a significant depth.

To determine the capacity of a friction pile, it is necessary to calculate the frictional resistance developed per unit area of the pile surface. This can be done by multiplying the pile surface area by the safe friction force. It is important to evaluate the required skin friction and consider safety factors when determining the pile’s capacity. Increasing the friction pile capacity can be achieved by adjusting factors such as diameter, number of piles, surface roughness, and depth.

Among the various materials used for friction piles, steel pipe piles are highly reliable and structurally sound. They offer a significant surface area that connects with the surrounding soil, providing powerful frictional load resistance. Steel-concrete composite piles are also popular for their durability and enhanced driveability. When it comes to friction pile construction, H-piles and wide flange beams are commonly used. H-piles are characterized by their broad shape and equal thickness in the rim and web, making them deep and suitable for friction pile applications.

In conclusion, friction piles play a crucial role in establishing a strong and stable foundation for large and heavy structures. By utilizing the frictional resistance between the pile surface and the surrounding soil, these piles effectively transfer the load of the superstructure. Steel pipe piles, particularly in combination with concrete, offer durability and versatility, making them a reliable choice for friction pile applications. When undertaking deep foundation projects, it is essential to consult with experts who can provide guidance on selecting the appropriate type of friction piles for optimal results.

Advantages of Steel Pipe for Friction Pile

Steel pipe piles offer several advantages when used as friction piles:

- Strength and Durability: Steel pipes are known for their high strength and durability, making them suitable for supporting heavy loads. They can withstand the stresses and strains imposed during installation and the service life of the structure.

- Corrosion Resistance: Steel pipes can be coated or galvanized to enhance their corrosion resistance. This is particularly important for friction piles that are exposed to moisture or corrosive environments, such as marine or industrial settings.

- Versatility: Steel pipes come in various sizes, lengths, and thicknesses, allowing for flexibility in design and installation. They can be easily cut, welded, and joined to meet specific project requirements.

- Ease of Installation: Steel pipe piles can be installed using various methods, including driving, drilling, or jetting. The installation process is relatively quick and efficient, saving time and labor costs.

- Cost-Effective: Steel pipe piles offer a cost-effective solution for foundation systems. They have a long service life and require minimal maintenance, resulting in reduced life-cycle costs.

Specifications for Steel Pipe Piles

When selecting steel pipe piles for friction pile applications, it is important to consider the following specifications:

- Pipe Material: The most commonly used material for steel pipe piles is ASTM A252 Grade 3, which is a structural-grade steel with a minimum yield strength of 45 ksi (310 MPa). Other materials, such as ASTM A500 or API 5L, may also be suitable depending on the project requirements.

- Pipe Size and Thickness: Steel pipe piles are available in various sizes and thicknesses, typically ranging from 8 inches to 120 inches in diameter. The thickness of the pipe wall should be selected based on the anticipated loads and soil conditions.

- Pipe Coating: To enhance corrosion resistance, steel pipe piles can be coated with protective coatings such as fusion-bonded epoxy (FBE), polyethylene (PE), or polyurethane (PU). The coating thickness should comply with industry standards and project specifications.

- Pipe Length: Steel pipe piles are typically manufactured in standard lengths of 40 feet (12 meters) or 60 feet (18 meters). Longer lengths can be achieved through splicing or welding multiple sections together.

Design and Installation Considerations

Designing and installing steel pipe piles for friction pile applications require careful consideration of the following factors:

- Soil Conditions: The frictional resistance between the pile and the surrounding soil is crucial for the load-bearing capacity of friction piles. Soil properties, such as cohesion, angle of internal friction, and soil stratification, should be evaluated to determine the appropriate pile diameter and length.

- Pile Spacing and Layout: The spacing and layout of steel pipe piles should be designed to distribute the load evenly and minimize differential settlement. Factors such as the magnitude and distribution of loads, soil bearing capacity, and pile group effects should be considered during the design process.

- Installation Method: The selection of the installation method depends on site conditions, pile length, and project requirements. Common methods include driving the piles using a pile hammer, drilling the piles into the ground, or jetting the piles with water or air.

- Quality Control and Testing: Quality control measures, such as pile integrity testing and pile load testing, should be implemented to ensure the proper installation and performance of steel pipe piles. These tests help verify the pile capacity, integrity, and load transfer characteristics.

FAQ

Q1: Can steel pipe piles be used in both onshore and offshore applications?

Yes, steel pipe piles are suitable for both onshore and offshore applications. However, additional considerations, such as corrosion protection and environmental factors, need to be taken into account for offshore installations.

Q2: What are the advantages of using coated steel pipe piles?

Coated steel pipe piles provide enhanced corrosion resistance, extending the service life of the piles. They are particularly beneficial in environments with high moisture, chemical exposure, or corrosive soils.

Q3: How are steel pipe piles connected or spliced together?

Steel pipe piles can be connected or spliced together using various methods, including welding, mechanical splicing, or using connectors such as flanges or couplings. The method of connection depends on the project requirements and the pile installation method.

Q4: What are the typical load-bearing capacities of steel pipe piles?

The load-bearing capacity of steel pipe piles depends on factors such as pile diameter, length, soil conditions,