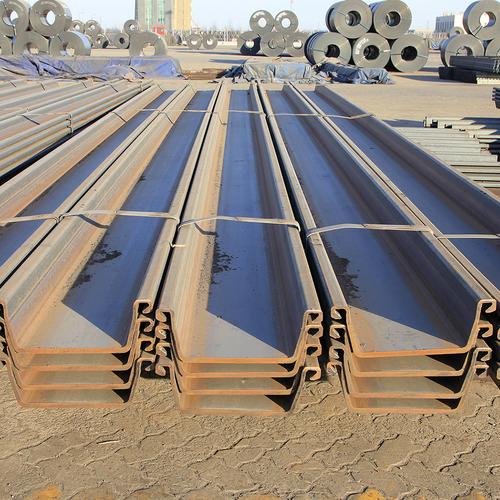

U-type steel sheet piles are a type of steel piling material used in construction. They are long, vertical sections made of steel that interlock with each other, forming a continuous wall to retain soil or water. The “U” shape allows these piles to be driven into the ground and form a strong, sturdy wall.

Here’s a more detailed explanation:

U-type Steel Sheet Piles

U-type steel sheet piles have a U-type cross-section, which helps to increase their strength and rigidity. They are typically made of high-grade steel, which provides excellent resistance to corrosion and degradation.

These piles are driven into the ground using a vibrating hammer, impact hammer, or a press-in machine. Once installed, they form a continuous wall which can be used for several purposes:

- Retaining Walls: They can be used to form retaining walls in construction sites, creating a stable and safe area for construction work.

- Flood Protection: In areas prone to flooding, these piles can be used to create barriers that prevent water intrusion.

- Ports and Harbors: They are used to construct the walls of ports and harbors, protecting them from water erosion.

- Tunnels and Bridges: These piles can also be used in the construction of bridges and tunnels, providing structural support.

Benefits of U-type Steel Sheet Piles

The use of U-type steel sheet piles offers several advantages:

- Strength and Durability: They are made of high-quality steel, which makes them highly durable and resistant to corrosion.

- Versatility: They can be used in a variety of construction projects, from retaining walls to tunnels.

- Efficiency: The interlocking design makes the installation process quick and efficient.

- Cost-Effective: They can be reused in different projects, reducing the overall cost.

Limitations and Considerations

Like all construction materials, U-type steel sheet piles also have their limitations:

- Installation Noise and Vibration: The installation process can cause noise and vibration which may be disruptive in populated areas.

- Limitation in Hard Soil or Rocks: Driving these piles into very hard soil or rock can be challenging and time-consuming.

- Design Complexity: Designing a structure with these piles requires sophisticated engineering tools and expertise.

Overall, U-type steel sheet piles are a versatile and robust solution for many construction needs. However, their use should be carefully planned and executed by experienced professionals.