Wedge wire screens, also known as profile wire screens, are commonly used in various industries for their superior screening capabilities. They are constructed from triangular-shaped wire, known as wedge wire or V-wire, which is welded onto support rods in a design that leaves open slots for filtration. The unique design of wedge wire screens allows for a high level of precision in separating solids from liquids, making them ideal for a range of applications including water treatment, food and beverage processing, petrochemical processing, and more.

Here are the different types of wedge wire screens:

- Flat Panels: These are used in a wide range of industrial applications for sizing, dewatering, and classification.

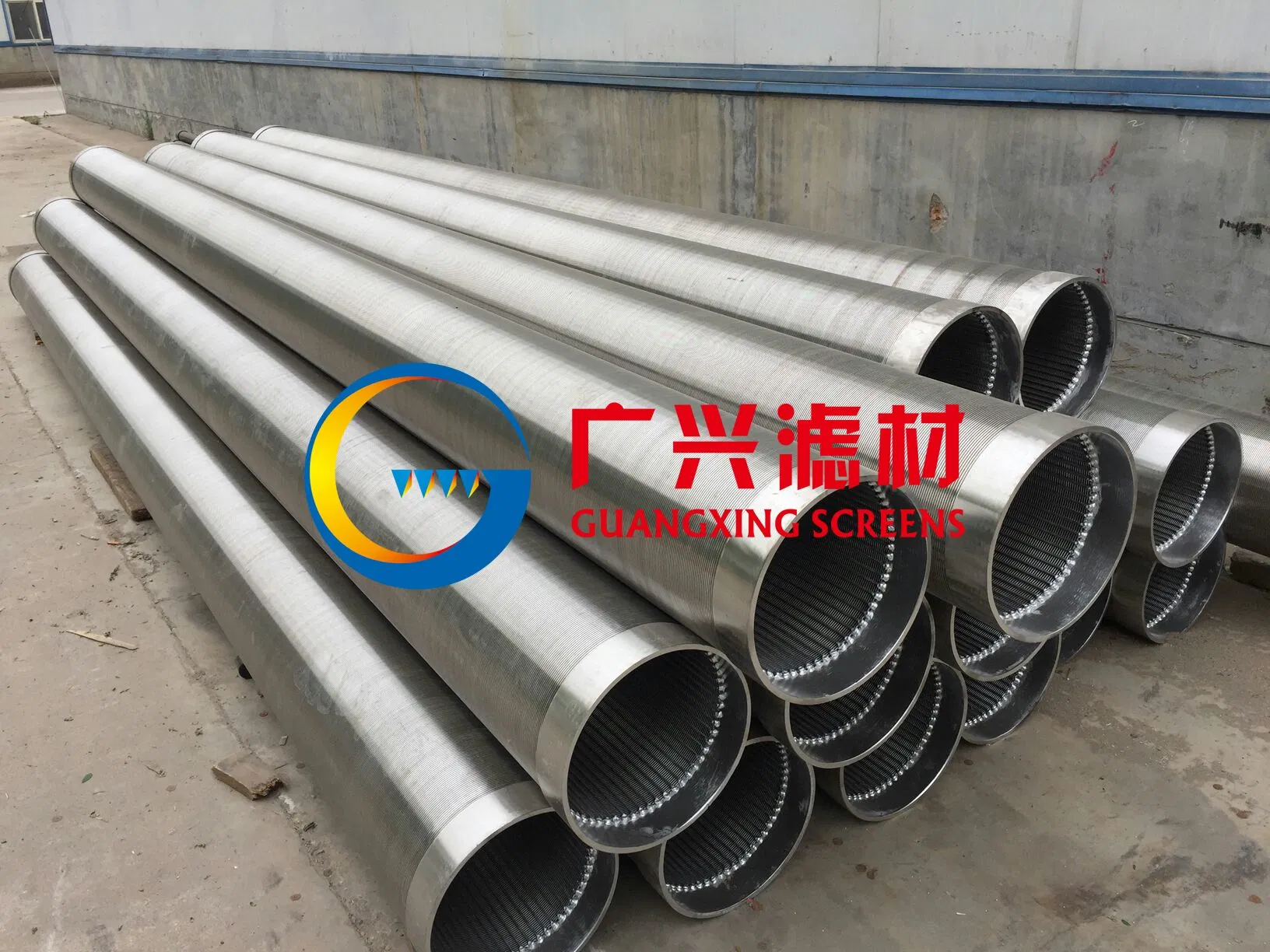

- Cylinder wedge wire screens: Also known as rotary screens, these are typically used in cylindrical applications, such as in screw press separators, classifiers, and centrifuges.

- Sieve Bend Screens: These have a curved screen design and are often used in static sieves for liquid/solid separation.

- Basket wedge wire screens: These are used in centrifuges, resin traps, and other applications that require a cylindrical screen with an open top and bottom.

- Laterals and Hub Radial Systems: These are used in under-drain systems for water treatment applications and are designed to distribute water evenly while removing particulates.

- Resin Traps: These are designed to capture media particles in water treatment systems and prevent them from escaping downstream.

- Conical Screens: These are used in brewing equipment, where they aid in the separation of solids from liquids during the brewing process.

Each type of wedge wire screens offers unique advantages in terms of flow rate, load capacity, and filtering precision, which makes them suitable for different applications. The type used depends on the specific requirements of the application, including the nature of the material being filtered, the desired flow rate, and the size of the particles to be separated.

What are the advantages of using wedge wire screens over other types of screens?

Wedge wire screens offer several advantages over other types of screens, making them a preferred choice in numerous industries for applications that require precise filtration. Here are some of the key advantages:

- High Precision Filtration: The unique wedge-shaped wire design allows for precise control over the size of particles that can pass through the screen, ensuring high-accuracy filtration.

- Non-Clogging Design: The triangular shape of the wires and the resultant slot design make wedge wire screens less prone to clogging, as particles are less likely to get stuck in the slots.

- High Structural Strength: The welding points of the wire provide high structural strength, which means the screens can withstand high pressures and loads.

- High Open Area: Wedge wire screens have a high percentage of open area, which allows for greater flow rates with lower pressure drops. This makes them more efficient in terms of energy use.

- Durability: Wedge wire screens are typically made from stainless steel or other durable materials, which makes them resistant to rust, corrosion, and wear. This results in a long service life and lower maintenance costs.

- Versatility: They can be custom made in a wide range of shapes, sizes, and configurations to meet specific application requirements.

- Easy to Clean: The smooth surface of the wedge wire and its non-clogging design make it easy to clean, further contributing to its long service life.

- Environmentally Friendly: Due to their durability and long service life, these screens are more environmentally friendly as they don’t need to be replaced as frequently.

Given these advantages, wedge wire screens are widely used in water treatment, food and beverage processing, waste treatment, petrochemical processing, and other industries that require solid-liquid separation or filtering.