Z-shaped steel sheet piles are a type of steel piling material that are used in construction, similar to U-shaped piles. The primary difference is their shape – Z-shaped piles have a Z-shaped cross section, which allows for greater swing or rotation during installation, resulting in a tighter interlock. This makes Z-shaped piles particularly useful for retaining walls and other structures that require significant lateral load resistance.

Here’s a more detailed overview:

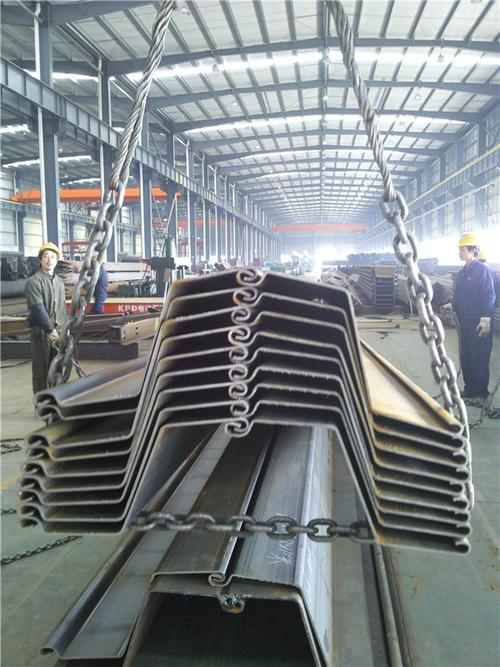

Z-Shaped Steel Sheet Piles

Z-shaped steel sheet piles have a Z-shaped cross section, which gives them a unique set of benefits:

- Greater Load Resistance: The shape allows for greater resistance to bending. This makes Z-shaped steel sheet piles ideal for projects that require strong lateral load resistance.

- Tighter Interlock: The Z-shape allows for a tighter interlock between the piles, creating a more secure and sturdy wall after installation.

- Versatility: Z-shaped piles can be used in a variety of projects, such as retaining walls, cofferdams, and sea walls.

- Durability: Like U-shaped piles, Z-shaped steel sheet piles are made from high-quality steel, making them durable and resistant to corrosion.

Advantages of Z-Shaped Steel Sheet Piles

- Strength and Rigidity: The Z-shaped cross section provides a high moment of inertia, resulting in a sheet pile with great strength and rigidity.

- Effective Interlock: The interlock on Z-shaped sheet piles is located at the extreme ends of the wall, away from the neutral axis. This means that up to 50% higher load can be transferred to the surrounding soil, providing a more efficient use of steel.

- Versatility: They can be used in nearly any type of soil and are suited for both temporary and permanent applications.

Z-shaped pile

Limitations and Considerations

Like all construction materials, Z-shaped steel sheet piles also have their limitations:

- Installation Complexity: The installation of Z-shaped piles can be more complex due to their shape. This can increase the time and cost of installation.

- Design Complexity: Designing a structure with these piles requires careful planning and expert engineering.

- Potential for Higher Costs: While Z-shaped piles offer greater load resistance and a tighter interlock, these benefits may come at a higher cost compared to other types of piles.

Overall, Z-shaped steel sheet piles are a robust and versatile solution for a variety of construction needs, particularly in situations that require significant lateral load resistance. However, their use should be carefully planned and executed, taking into account the complexity of installation and potential cost implications.

Hot Rolled steel sheet pile

| Section | width (mm) |

height (mm) |

Web (mm) |

Cross-Sectional Area | Weight | Section Modulus | Moment of Inertia (cm4/m) |

Coating Area | ||||

| (cm2/m) | (cm2/m) | Pile (kg/m) |

Wall (kg/m2) |

Elastic (cm3/m) |

Plastic (cm3/m) |

Both Sides of Single

(m2/m) |

Wall Surface (m2/m2) |

|||||

| JZ17-700 | 700 | 419.5 | 8.5 | 93.3 | 133.2 | 73.2 | 104.6 | 1731 | 2031 | 36304 | 1.86 | 1.33 |

| JZ18-700 | 700 | 420 | 9 | 97.7 | 139.5 | 76.7 | 109.5 | 1804 | 2120 | 37894 | 1.86 | 1.33 |

| JZ19-700 | 700 | 420.5 | 9.5 | 102.1 | 145.9 | 80.1 | 114.5 | 1878 | 2213 | 39485 | 1.86 | 1.33 |

| JZ20-700 | 700 | 421 | 10 | 106.5 | 152.2 | 83.6 | 119.4 | 1951 | 2302 | 41076 | 1.86 | 1.33 |

| JZ24-700 | 700 | 439 | 11 | 121.2 | 173.1 | 95.1 | 135.9 | 2432 | 2818 | 53379 | 1.93 | 1.38 |

| JZ26-700 | 700 | 440 | 12 | 130.6 | 186.6 | 102.5 | 146.5 | 2606 | 3030 | 57329 | 1.93 | 1.38 |

| JZ28-700 | 700 | 441 | 13 | 140 | 200 | 109.9 | 157 | 2779 | 3240 | 61279 | 1.93 | 1.38 |

| JZ36-700 | 700 | 499 | 11 | 150.5 | 215 | 118.1 | 168.8 | 3600 | 4111 | 89826 | 2.05 | 1.47 |

| JZ38-700 | 700 | 500 | 12 | 160.4 | 229.2 | 125.9 | 179.9 | 3800 | 4357 | 95004 | 2.05 | 1.47 |

| JZ40-700 | 700 | 501 | 13 | 170.3 | 243.3 | 133.7 | 191 | 3999 | 4604 | 100184 | 2.05 | 1.47 |

Contrast material

| Standard | Grade | Chemical composition | ||||||||||

| C | Si | Mn | P | S | Nb | V | Ti | Cu | N | free nitrogen | ||

| ≤ | ||||||||||||

| JIS A 5528 | SY295 | 0.04 | 0.04 | |||||||||

| SY390 | 0.04 | 0.04 | ||||||||||

| JIS A 5523 | SYW295 | 0.18 | 0.55 | 0.15 | 0.04 | 0.04 | 0.006 | |||||

| SYW390 | 0.18 | 0.55 | 0.15 | 0.04 | 0.04 | 0.006 | ||||||

| GB1591 | Q345B | 0.2 | 0.5 | 1.7 | 0.035 | 0.035 | 0.07 | 0.15 | 0.2 | 0.3 | 0.12 | |

| GB/T20933-2014 | Q295P | 0.16 | 0.5 | 1.5 | 0.035 | 0.035 | 0.06 | 0.15 | 0.2 | |||

| Q345P | 0.2 | 0.5 | 1.7 | 0.035 | 0.035 | 0.06 | 0.15 | 0.2 | ||||

| Q390P | 0.2 | 0.5 | 1.7 | 0.035 | 0.035 | 0.06 | 0.2 | 0.2 | ||||

| Q420P | 0.2 | 0.5 | 1.7 | 0.035 | 0.035 | 0.06 | 0.2 | 0.2 | ||||

| Q460P | 0.2 | 0.6 | 1.8 | 0.03 | 0.03 | 0.11 | 0.2 | 0.2 | ||||