Outline for “Z-Shaped Steel Sheet Piles for Construction”

| Main Topics | Subtopics |

|---|---|

| Introduction to Z-Shaped Steel Sheet Piles | – What are Z-shaped steel sheet piles? – Importance in construction |

| Features of Z-Shaped Steel Sheet Piles | – Design and geometry – Durability and material composition |

| Applications of Z-Shaped Steel Sheet Piles | – Retaining walls – Cofferdams – Marine and port construction – Bridge abutments |

| Advantages of Z-Shaped Steel Sheet Piles | – Structural strength – Easy installation and reusability – Cost-effectiveness |

| Comparison Between Z-Shaped and U-Shaped Sheet Piles | – Key design differences – Strength and performance comparison – Applications suited for each |

| Material Composition of Z-Shaped Steel Sheet Piles | – Types of steel used – Role of coatings in corrosion resistance |

| Manufacturing Process of Z-Shaped Steel Sheet Piles | – Hot rolling vs cold rolling – Quality control measures |

| Installation Methods for Z-Shaped Steel Sheet Piles | – Driving techniques: impact driving, vibratory driving, hydraulic pressing – Equipment required |

| Challenges in Using Z-Shaped Steel Sheet Piles | – Handling and transportation – Installation difficulties in specific soil types |

| Maintenance of Z-Shaped Steel Sheet Piles | – Regular inspections – Repair techniques – Extending lifespan through coatings and treatments |

| Cost Analysis of Z-Shaped Steel Sheet Piles | – Initial costs – Long-term benefits and savings – Cost comparison with other retaining systems |

| Case Studies of Z-Shaped Steel Sheet Piles in Construction | – Examples from marine construction – Usage in flood protection systems – Urban retaining wall projects |

| Environmental Impact of Z-Shaped Steel Sheet Piles | – Sustainable construction practices – Recycling and reusability – Mitigating ecological concerns |

| Design Considerations for Z-Shaped Steel Sheet Piles | – Load-bearing capacity – Soil interaction and geotechnical considerations – Compatibility with other construction materials |

| Future Trends in Z-Shaped Steel Sheet Pile Technology | – Innovations in design – Emerging materials – Improved installation techniques |

| FAQs on Z-Shaped Steel Sheet Piles | – Common questions answered about Z-shaped steel sheet piles |

Z-Shaped Steel Sheet Piles for Construction

Z-shaped steel sheet piles are an essential component in modern construction projects, offering unmatched versatility, durability, and structural strength. Whether used in retaining walls, cofferdams, or marine construction, these sheet piles provide the backbone of countless infrastructure projects worldwide. This article explores everything you need to know about Z-shaped steel sheet piles, from their features and applications to their installation and cost analysis.

Introduction to Z-Shaped Steel Sheet Piles

Z-shaped steel sheet piles are structural elements with a unique geometry resembling the letter “Z” when viewed in cross-section. This design allows for higher strength and interlocking capabilities, making them a preferred choice in construction projects where structural integrity is paramount.

Importance in Construction

Steel sheet piles are widely used for creating retaining walls, stabilizing soil, and protecting structures from water intrusion. The Z-shaped configuration provides higher resistance to bending forces, which is particularly useful in applications such as flood protection, marine structures, and deep foundations.

Features of Z-Shaped Steel Sheet Piles

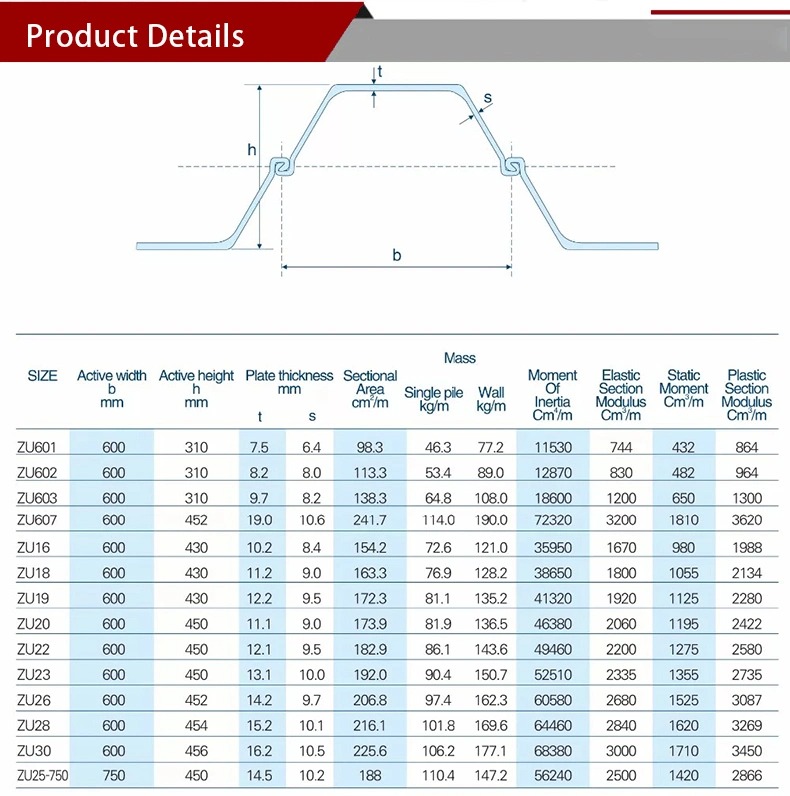

1. Design and Geometry

The Z-shaped configuration ensures that the centerline of the wall and the neutral axis align, leading to optimal load distribution. This feature makes them more efficient compared to other types of sheet piles like U-shaped piles.

2. Durability and Material Composition

Made from high-strength steel, Z-shaped piles can withstand extreme forces. Corrosion-resistant coatings further enhance their longevity, particularly in environments exposed to water or corrosive substances.

Applications of Z-Shaped Steel Sheet Piles

1. Retaining Walls

Z-shaped piles are ideal for retaining walls, preventing soil erosion and providing stability in urban and rural environments. They are widely used for slope stabilization and excavation support.

2. Cofferdams

Cofferdams made from Z-shaped steel sheet piles are essential in constructing bridges, docks, and other structures requiring a dry work environment within water bodies.

3. Marine and Port Construction

In marine environments, Z-shaped piles form robust seawalls and bulkheads, offering protection against waves and tidal forces.

4. Bridge Abutments

Z-shaped steel sheet piles provide support for bridge abutments, ensuring structural integrity even in challenging geotechnical conditions.

Advantages of Z-Shaped Steel Sheet Piles

1. Structural Strength

The interlocking design of Z-shaped piles ensures high load-bearing capacity and resistance to lateral forces.

2. Easy Installation and Reusability

Z-shaped steel sheet piles can be driven into the ground using vibratory hammers or impact drivers, making installation quick and efficient. They can also be extracted and reused in different projects.

3. Cost-Effectiveness

Due to their durability and reusability, Z-shaped piles offer a cost-effective solution for long-term projects.

Comparison Between Z-Shaped and U-Shaped Sheet Piles

| Aspect | Z-Shaped Piles | U-Shaped Piles |

|---|---|---|

| Design | Z-shaped with continuous interlocks | U-shaped with paired interlocks |

| Strength | Higher bending moment resistance | Lower bending moment resistance |

| Applications | Ideal for large-scale and deep projects | Suitable for light-duty applications |

| Cost | Generally higher initial cost | More affordable for smaller projects |

Material Composition of Z-Shaped Steel Sheet Piles

1. Types of Steel Used

Z-shaped piles are typically made from high-grade structural steel with excellent tensile strength. Common steel grades include ASTM A572 and EN 10248.

2. Role of Coatings

To prevent corrosion, Z-shaped steel sheet piles are often coated with protective layers like galvanized zinc, epoxy, or polyurethane.

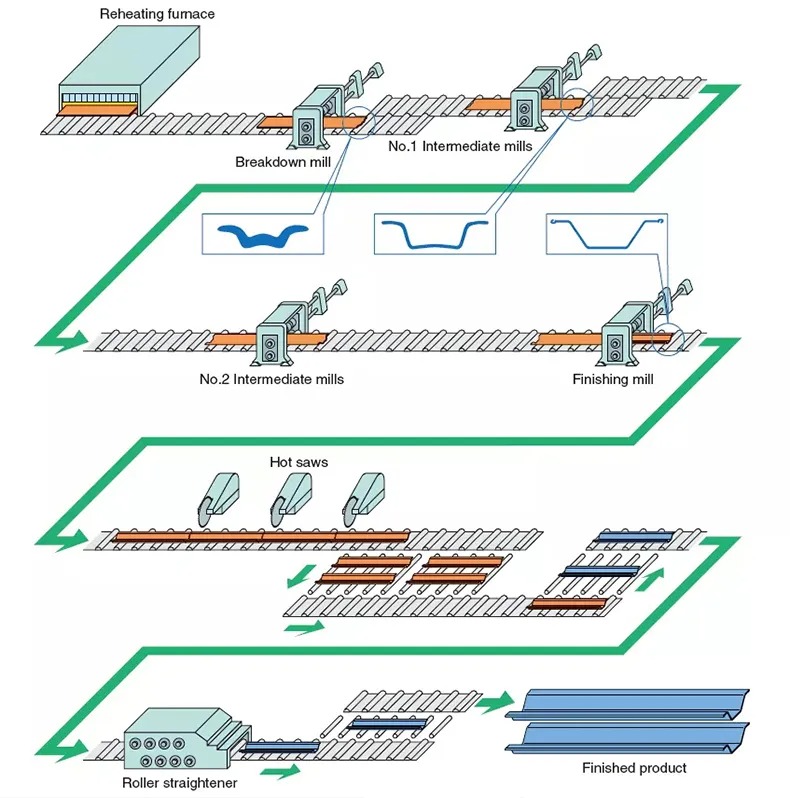

Manufacturing Process of Z-Shaped Steel Sheet Piles

1. Hot Rolling vs Cold Rolling

Hot rolling produces thicker, stronger sheet piles suitable for heavy-duty applications, while cold rolling is used for lightweight and cost-effective alternatives.

2. Quality Control Measures

Strict quality checks, including ultrasonic testing and dimensional inspections, ensure that the piles meet construction standards.

Installation Methods for Z-Shaped Steel Sheet Piles

1. Driving Techniques

- Impact Driving: Uses a pile-driving hammer to embed the sheet pile into the ground.

- Vibratory Driving: Vibratory hammers create vibrations to ease the pile into the soil.

- Hydraulic Pressing: A quieter method suitable for noise-sensitive areas.

2. Equipment Required

Specialized equipment like cranes, driving rigs, and hammer attachments are essential for proper installation.

Challenges in Using Z-Shaped Steel Sheet Piles

1. Handling and Transportation

The large size and weight of Z-shaped piles require careful handling to prevent damage.

2. Installation in Difficult Soil Types

Dense or rocky soils may hinder the installation process, requiring additional pre-drilling or soil treatment.

Maintenance of Z-Shaped Steel Sheet Piles

Regular inspections help identify issues like corrosion or joint wear. Coatings and cathodic protection systems can extend the lifespan of the piles.

Cost Analysis of Z-Shaped Steel Sheet Piles

1. Initial Costs

While the upfront cost of Z-shaped piles may be higher than alternatives, their durability and reusability often make them a more economical choice in the long run.

2. Long-Term Savings

Reduced maintenance and repair costs contribute to significant savings over the lifespan of the project.

Case Studies of Z-Shaped Steel Sheet Piles in Construction

1. Marine Construction

Z-shaped piles were used to create a seawall protecting a coastal city from tidal surges.

2. Flood Protection Systems

A major flood protection project utilized Z-shaped piles to create a robust retaining wall system.

Environmental Impact of Z-Shaped Steel Sheet Piles

Steel sheet piles are highly recyclable, reducing waste in construction. Their durability minimizes the need for frequent replacements, further enhancing sustainability.

Design Considerations for Z-Shaped Steel Sheet Piles

Key factors include load-bearing capacity, soil conditions, and compatibility with other construction materials.

Future Trends in Z-Shaped Steel Sheet Pile Technology

Emerging materials like high-performance steel alloys and improved manufacturing processes are set to revolutionize the industry.

FAQs on Z-Shaped Steel Sheet Piles

1. What are Z-shaped steel sheet piles used for?

They are used for retaining walls, cofferdams, marine construction, and flood protection systems.

2. What makes Z-shaped piles different from U-shaped piles?

Z-shaped piles have higher strength and better load distribution, making them suitable for large-scale projects.

3. How are Z-shaped piles installed?

They are installed using techniques like vibratory driving, impact driving, or hydraulic pressing.

4. Are Z-shaped piles reusable?

Yes, they can be extracted and reused in different projects.

5. What coatings are applied to prevent corrosion?

Common coatings include galvanized zinc, epoxy, and polyurethane.

6. How do Z-shaped piles contribute to sustainability?

Their recyclability and long lifespan reduce environmental impact.

Z-shaped steel sheet piles are a cornerstone of modern construction, offering unmatched versatility, durability, and performance in a wide range of applications. Their unique design allows for higher load-bearing capacity and better interlocking capabilities compared to other sheet pile designs, making them the preferred choice for demanding projects like marine construction, flood protection systems, and deep excavation support.

By understanding their features, manufacturing process, installation methods, and environmental impact, construction professionals can make informed decisions when choosing Z-shaped sheet piles for their projects. As advancements in material technology and manufacturing processes continue, the future of Z-shaped steel sheet piles looks promising, with innovations set to further enhance their performance, efficiency, and sustainability.

Whether you’re a contractor, an engineer, or a project manager, investing in Z-shaped steel sheet piles can ensure the success and longevity of your construction projects while contributing to sustainable practices in the industry.