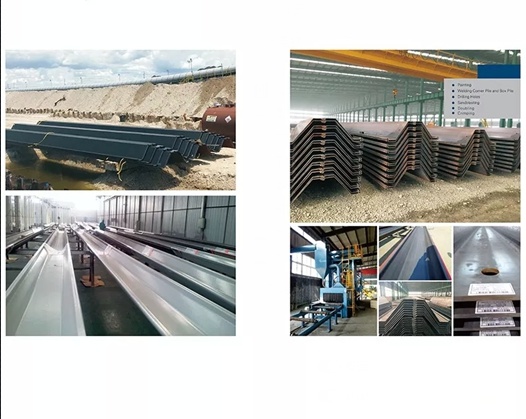

Z-type sheet piles are a versatile solution in civil engineering and construction due to their high strength, efficient design, and ease of installation. Here are some common applications where Z-shaped pile are used:

- Retaining Walls: These are structures designed to restrain soil to unnatural slopes. They are used to bound soils between two different elevations often in areas of terrain possessing undesirable slopes or in areas where the landscape needs to be shaped severely and engineered for more specific purposes.

- River Bank Protection: Z-type sheet piles are used to stabilize riverbanks and prevent soil erosion, especially in areas with high water flow or heavy wave action.

- Seawalls and Coastal Defenses: They are used to protect areas of human habitation, conservation, and leisure activities from the action of tides and waves. They prevent coastal erosion and provide flood protection.

- Port and Harbor Structures: They can be used to construct quay walls, jetties, and other harbor structures. They provide a durable and cost-effective solution for these types of marine infrastructure.

- Cofferdams: These are temporary structures built to exclude water from a work area in water bodies, allowing construction to take place. Z-type sheet piles can be driven into the seabed to form a watertight wall around the construction area.

- Flood Protection Walls: They can be used to construct flood defense walls to protect areas prone to flooding.

- Bridge Abutments: They are used to support the ends of bridges and to retain the soil at the bridge approaches.

- Basement and Underground Car Park Walls: In urban construction, they can be used to form the walls of basements and underground car parks.

- Tunnels: They are used in the construction of cut-and-cover tunnels, where the tunnel is first excavated and then covered over.

The use of Z-type sheet piles is not limited to these applications. They can be used in any situation where a strong, durable retaining structure is required.

Product Description

|

Products Name

|

china mild steel q235 q345 cold formed z type sheet pile sheet piling price

|

|||

|

Brand Name

|

Lukun

|

|||

|

Certificate

|

ISO9001

|

|||

|

Grade |

Q235 Q195 A36 A106 Q345,Q390. All Chinese Standard, EN Standard, ASTM Standard and other standard material are available on request.

|

|||

|

Technique

|

cold formed

|

|||

|

Type

|

Z type

|

|||

|

Length

|

any length as customer’s request

|

|||

|

Application

|

flood project, construction project, bridge etc.

|

|||

|

Package

|

bundle in bulk,seaworthy packing or as customer’s request

|

|||

|

Place of origin

|

China mainland

|

|||

|

Shipment

|

bulk vessel or container

|

|||

|

Delivery

|

In 15 days after receipt of L/C or TT

|

|||

|

|

Detailed specifications of china mild steel q235 q345 cold formed z type sheet pile sheet piling

1.More durable interlocks: This allows the sheets to be driven and pulled many times before the interlocks are worn out

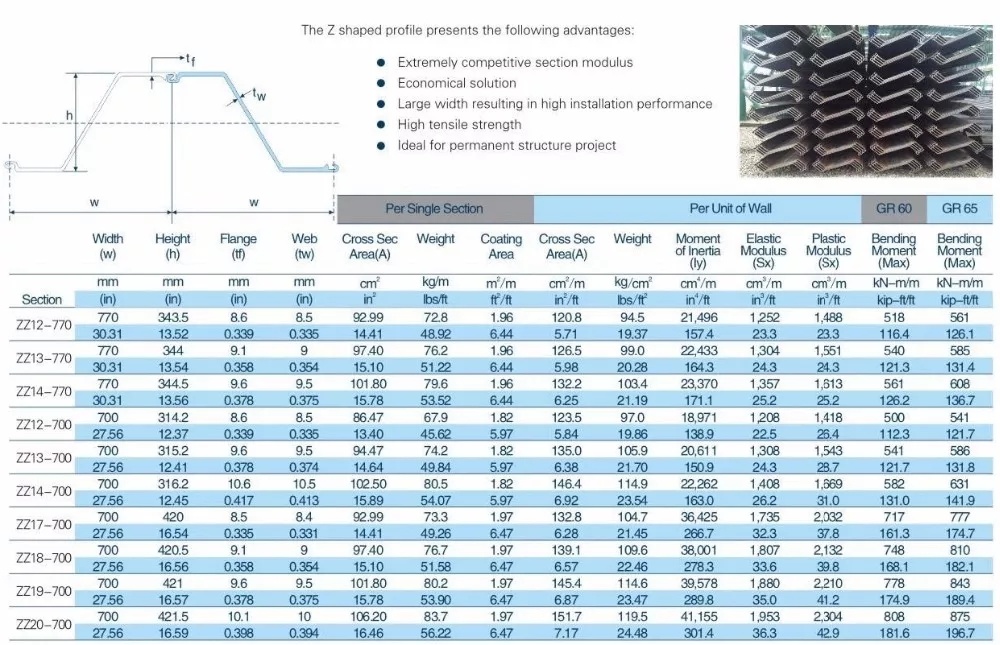

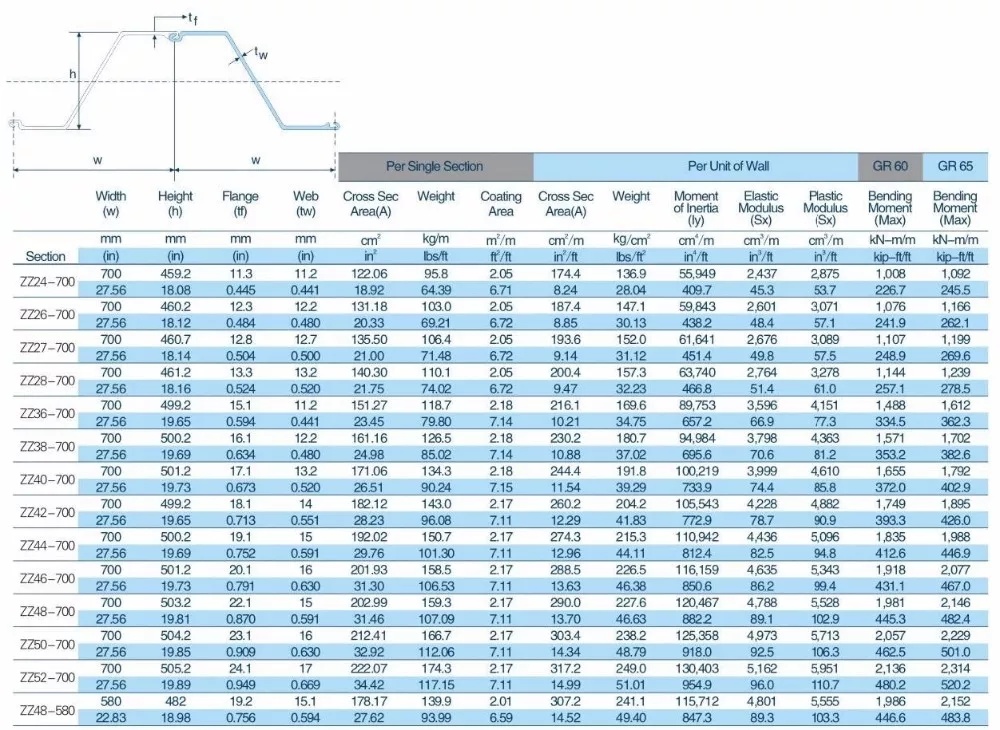

Extremely competitive section modulus

Economical solution

Large width resulting in high installation performance

High tensile strength

Applications

|

|